Camera module and assembling method

A technology of camera module and assembly method, which is applied in the field of electronics, can solve problems such as large eccentricity of the camera module, and achieve the effects of avoiding assembly tolerance, improving poor vision, and improving the problem of poor vision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

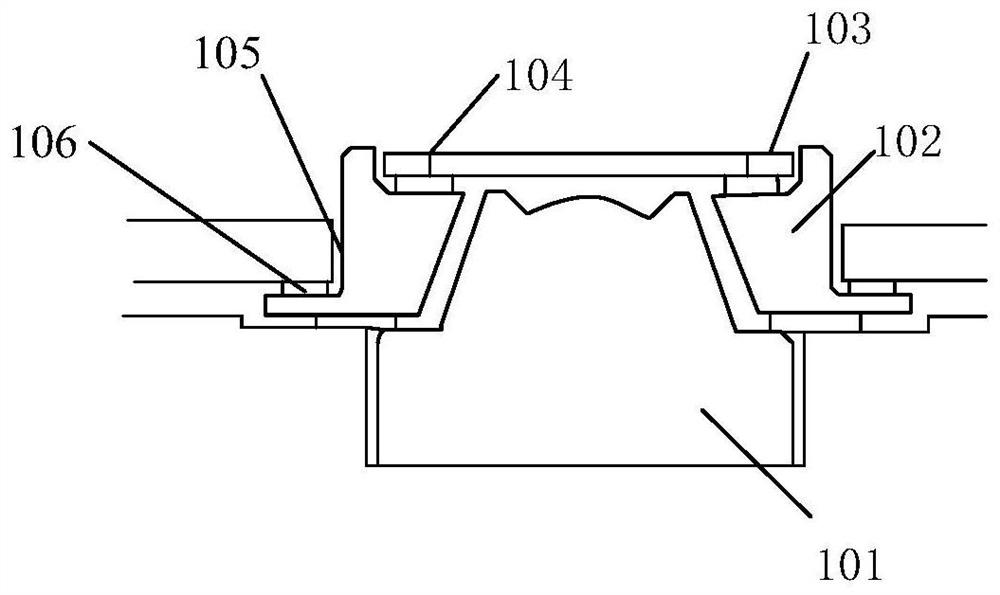

Image

Examples

other Embodiment approach

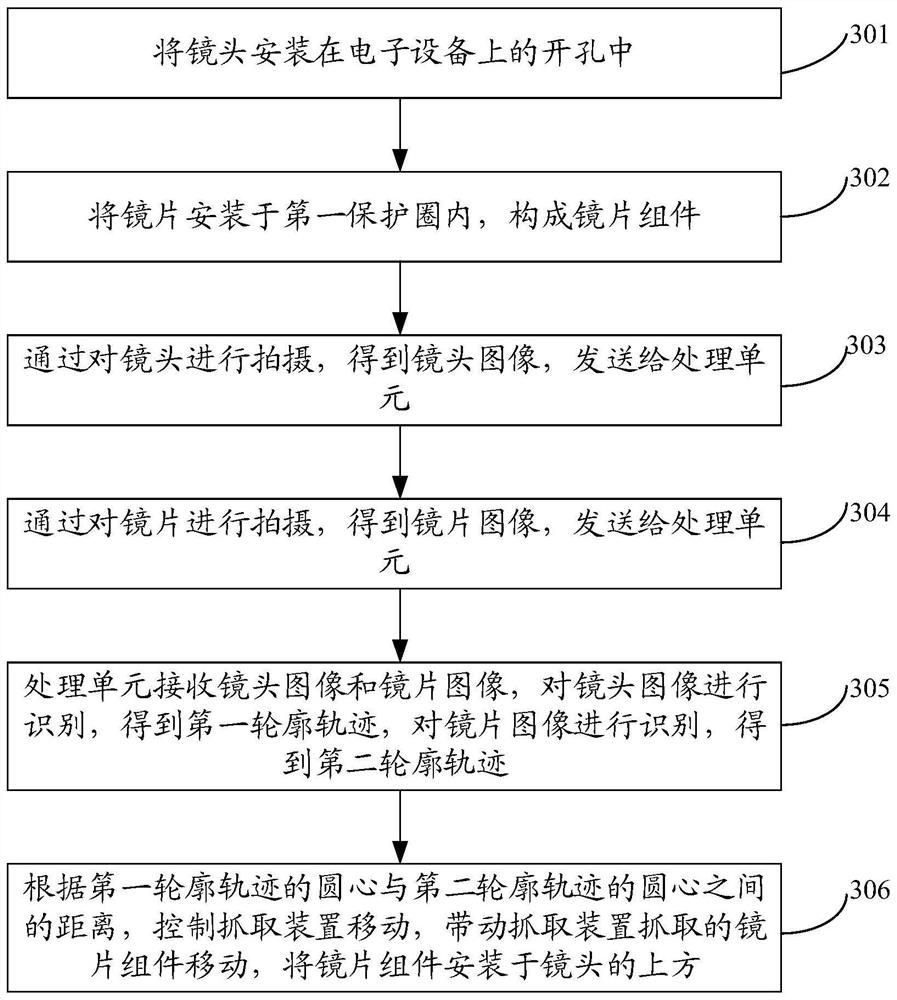

[0134] Other implementation manners are similar to the implementation manner of step 301 in the foregoing embodiment.

[0135] 502. Obtain a lens image by shooting the lens 601, and send it to the processing unit.

[0136] The implementation is similar to the implementation of step 303 in the above-mentioned embodiment, the difference is that in the embodiment of the present disclosure, when the lens 601 is photographed, the lens assembly is actually photographed to obtain an image of the lens assembly, the image includes the lens image, and the The image is sent to a processing unit, which extracts the lens image from the image.

[0137] 503. Obtain a lens image by photographing the lens 604, and send it to the processing unit.

[0138] The implementation manner is similar to the implementation manner of step 304 in the foregoing embodiment.

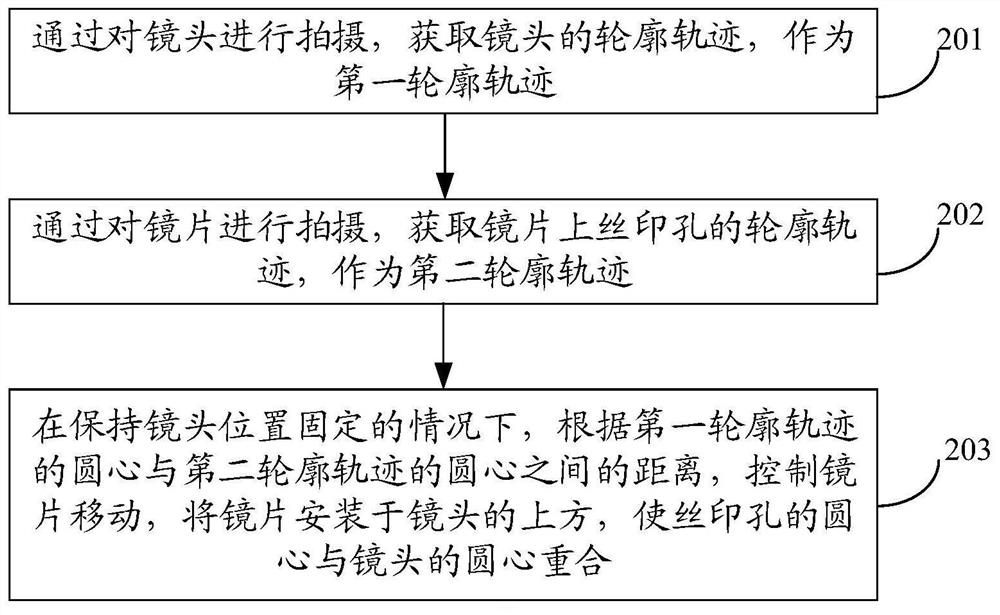

[0139] 504. The processing unit receives the lens image and the lens image, recognizes the lens image to obtain a first contour trajec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com