Side suspension type supporting device for traction motor test

A side-suspended, support device technology, applied in the direction of motor generator testing, measuring device casings, etc., can solve the problems of bulkiness, large test support device, poor versatility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

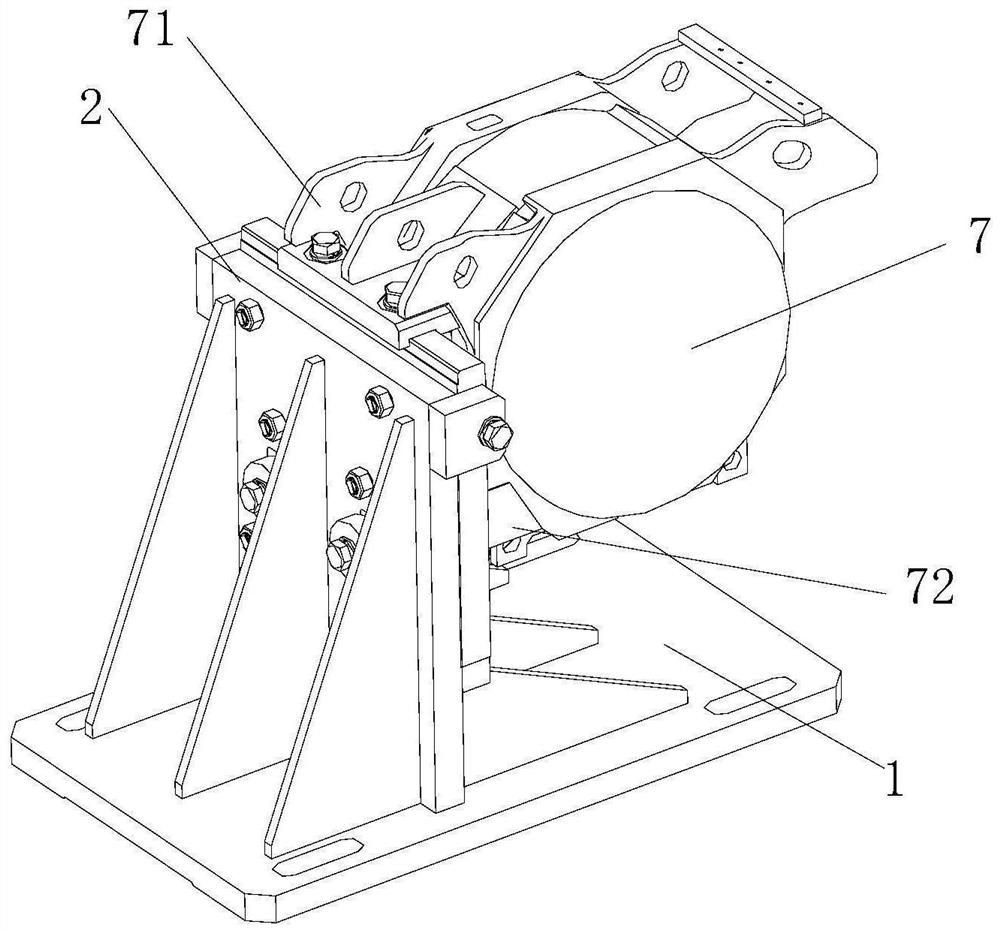

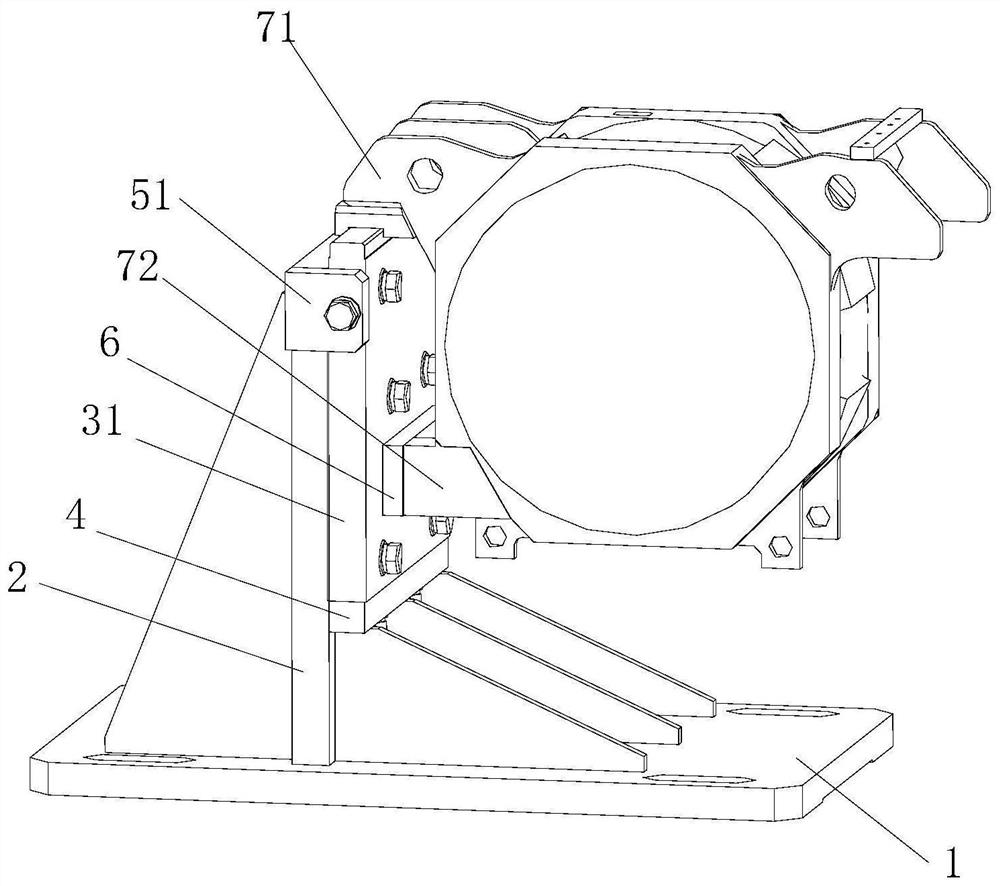

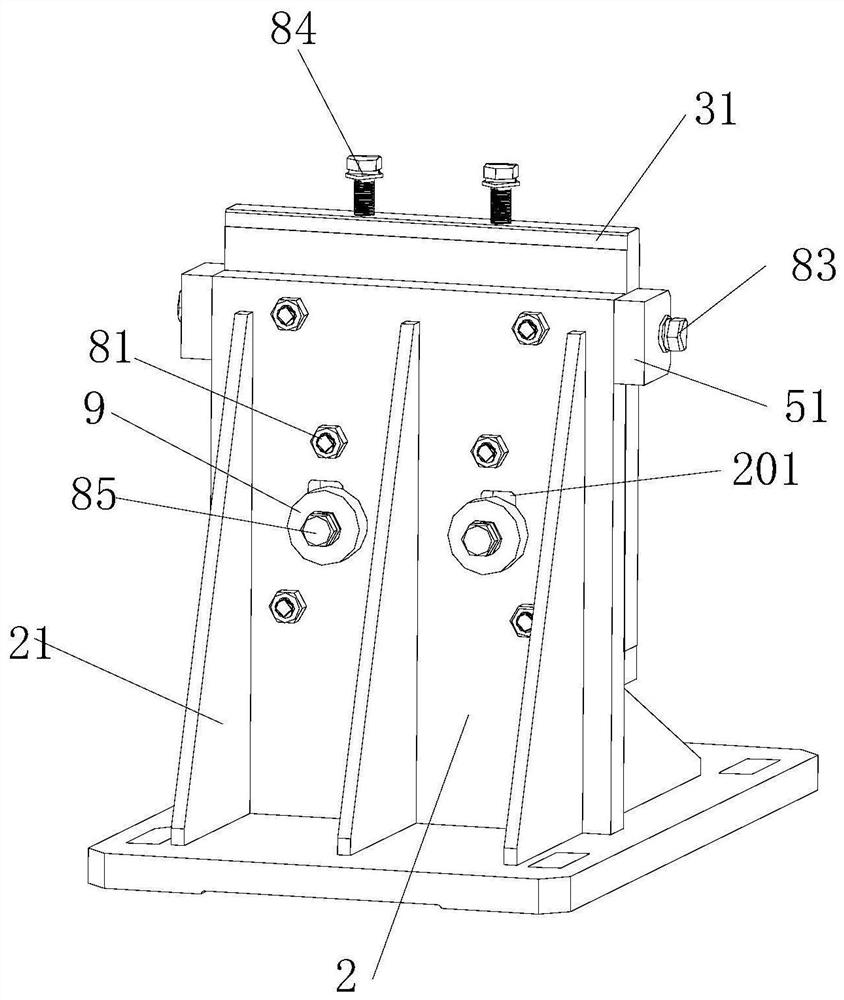

[0026]Such asFigure 1 to 4As shown, the traction motor test side suspension supporting means for the present embodiment, including the base 1, the frame 2, and the movable block 31, and the frame 2 is fixed to the base 1, and the movable block 31 is secured vertically through the first fastener. On the frame 2, the movable block 31 is remote from the side of the frame 2 to mount the motor, and the frame 2 is provided with a beam 4, and the upper end of the movable block 31 projects out of the rack 2, and the lower end is abutting on the beam 4, movable block 31 Between the beam 4, by the second fastener, the frame 2 is provided with a side stop 51 on both sides of the movable block 31, and the side stopper 51 is connected between the side stopper 51 and the movable blocks 31. 31 is located on one side of the frame 2, a block 6 is provided, and wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com