Improved leakage-proof universal half joint assembly

An improved technology of Huff joint, which is applied in the direction of connecting components, pipes/pipe joints/fittings, sleeves/sockets, etc. It can solve the problems of poor structural versatility, leakage of pipes, leakage of pipes, damage to devices, etc., and achieve installation Convenience, strong versatility, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

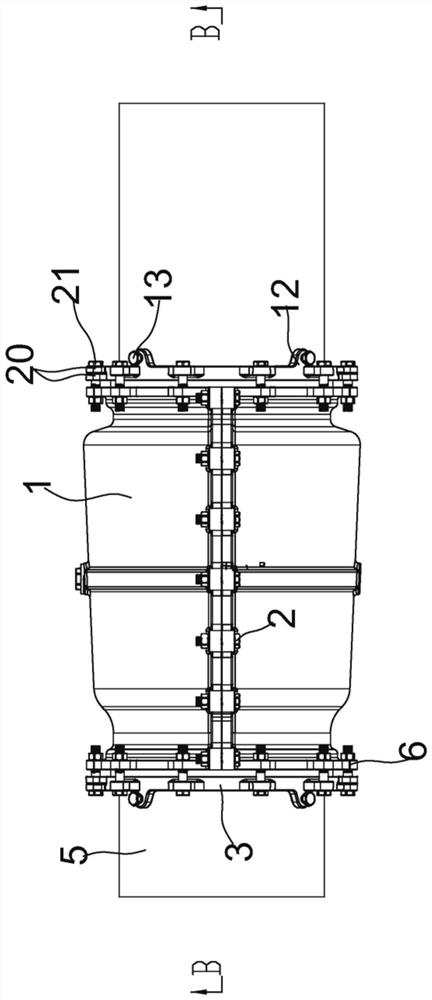

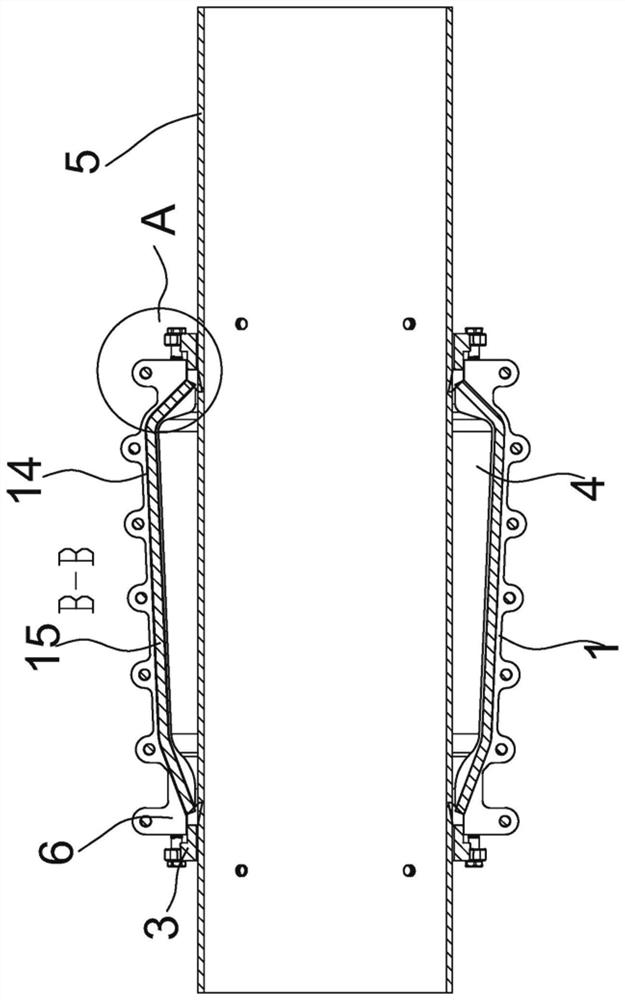

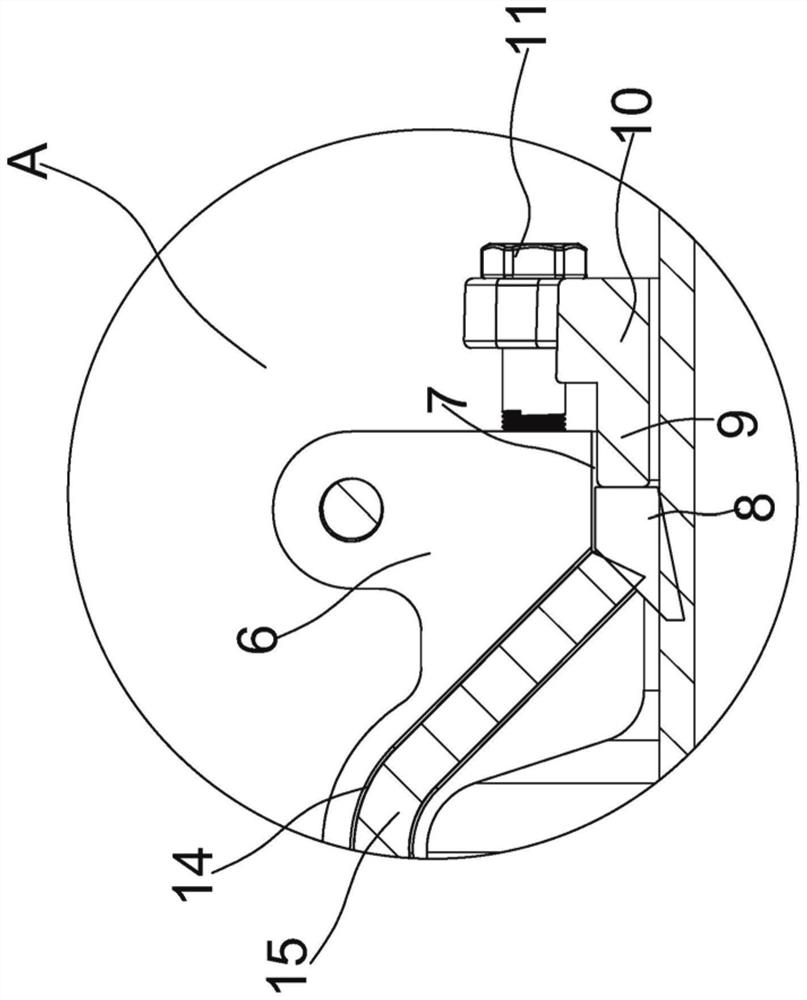

[0034] refer to Figure 1 to Figure 5As shown, what is disclosed in this embodiment is an improved leak-proof universal half-joint assembly, which includes two half-part half bodies 1 and several first connections for locking the two half-part half-parts 1 The bolt 2 is fixedly connected to the two socket joints 3 , that is, the two haf joint halves 1 through several first connecting bolts 2 . The socket joint 3 includes two socket halves 20 locked and enclosed by the third connecting bolt 21, the two socket halves 20 are enclosed together to form the socket joint 3, and the two socket halves 20 They are locked to each other by the third connecting bolt 21. The two haf joint halves 1 are provided with an accommodating cavity 4 through which the pipe 5 can pass. It should be noted that the pipe 5 is not part of the improved leak-proof universal half joint assembly in this embodiment, but It is the use object of the improved leak-proof universal half festival component in this...

Embodiment 2

[0042] refer to Figure 4 to Figure 7 As shown in Example 1, the embodiment of the present invention discloses an improved leak-proof universal half-joint assembly, which includes two half-joint halves 1 and several half-joint half-body 1 for locking the two half-joints. The first connecting bolt 2 and two socket joints 3, the socket joint 3 comprises two socket halves 20 closed by the third connecting bolt 21, and the two haf joint halves 1 are provided with The containment cavity 4 that can pass through the pipeline 5, the diameter of the middle part of the containment cavity 4 is greater than the diameter of the two ends, the diameters of the two ends of the containment cavity 4 are equal to and not smaller than the diameter of the pipeline 5, the left end and the right end of the two half-parts 1 Both parts are fixed with a first connecting flange 6, the first connecting flange 6 is integrally cast with the two haf joint halves 1, and the first connecting flange 6 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com