Swallowing and spitting type impurity removing device for fabric desizing process

A desizing and crafting technology, applied in the field of throughput cleaning device, can solve problems such as dyeing and finishing processing difficulties, affecting printing and dyeing effects, waste of water resources, etc., and achieve the effects of ingenious structure, improved practicability, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

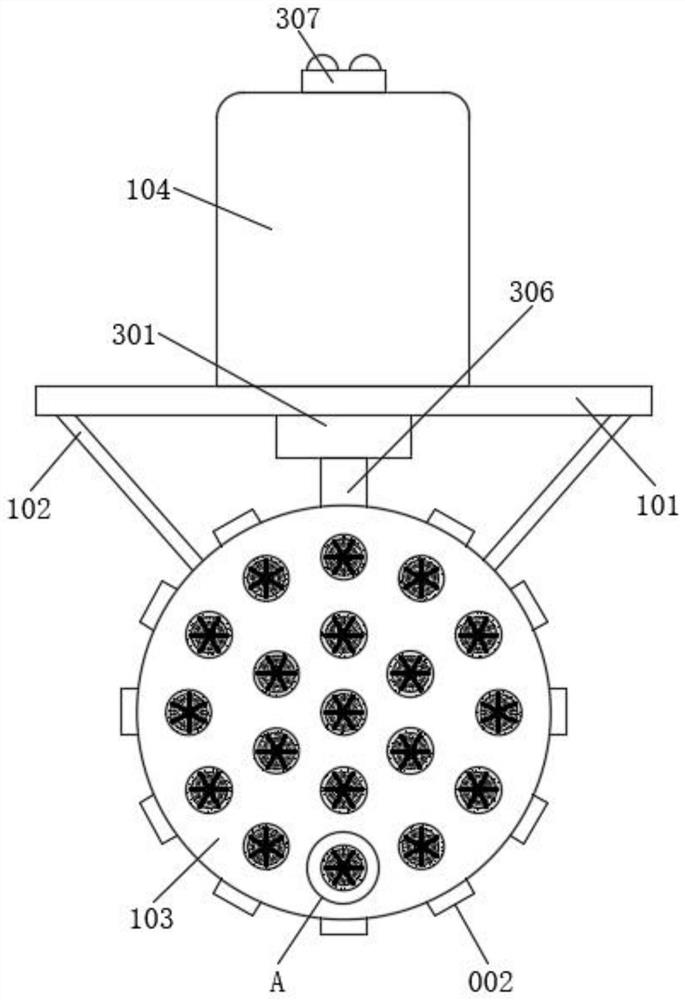

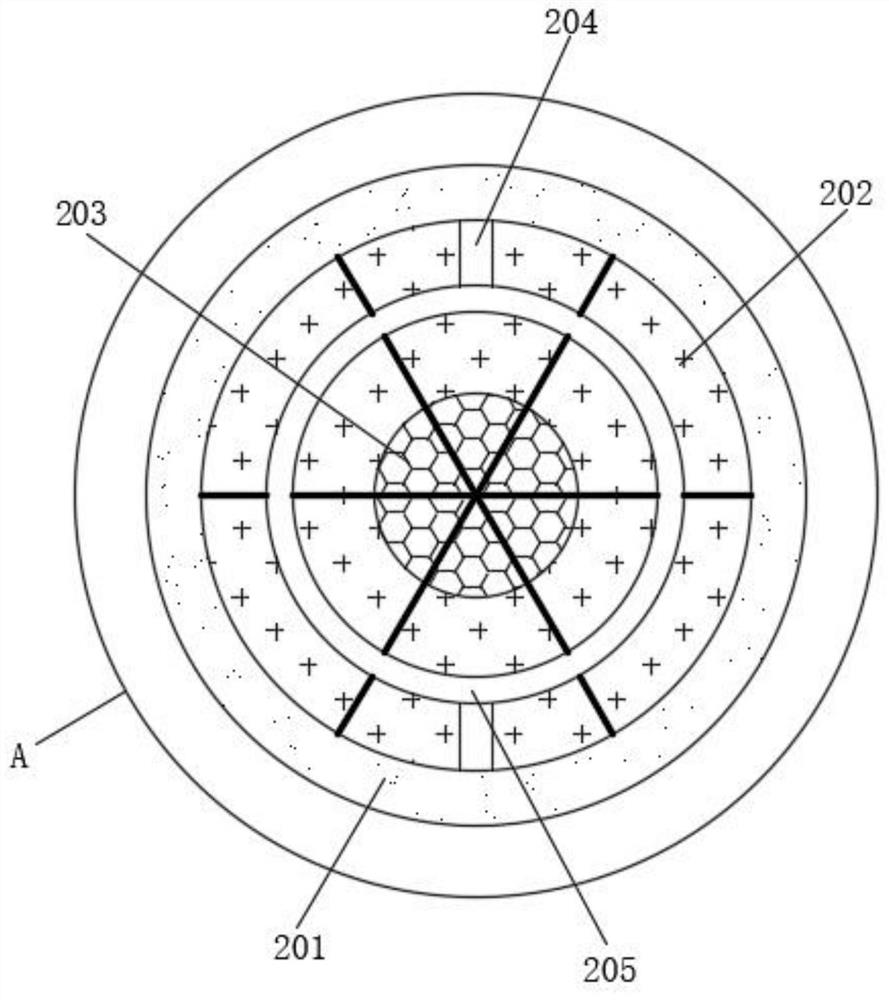

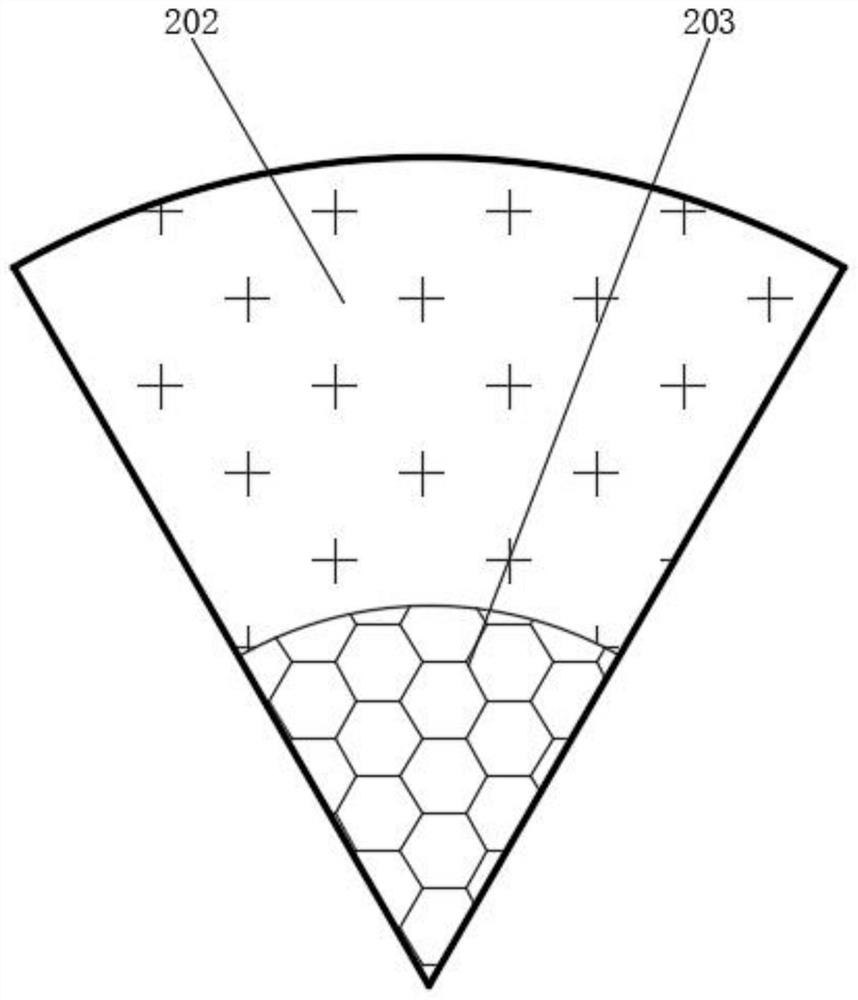

[0039] see Figure 1-4 , a throughput cleaning device for fabric desizing process, including a balance floating plate 101, the lower part of the balance floating plate 101 is fixedly connected with a support spherical shell 103 through two suspenders 102, and the outer wall of the support spherical shell 103 is set There are a plurality of throughput filter pipes 002, and the plurality of throughput filter pipes 002 are evenly distributed along the spherical surface of the supporting spherical shell 103. The throughput filter pipes 002 include the water inlet and outlet pipes 201 fixedly penetrating through the outer wall of the supporting spherical casing 103, and the inner walls of the water inlet and outlet pipes 201 are fixedly connected There are a plurality of fan-shaped filter sheets, and the plurality of fan-shaped filter sheets are evenly distributed in a ring shape, and the sides of two adjacent fan-shaped filter sheets are adjacent to each other. The fan-shaped filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com