Automatic feeding and color matching machine

A color matching machine and feeding technology, which is applied in the direction of mixers, dissolution, chemical instruments and methods, etc., can solve the problems of low mixing efficiency of materials, and achieve the effect of improving uniformity and color matching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

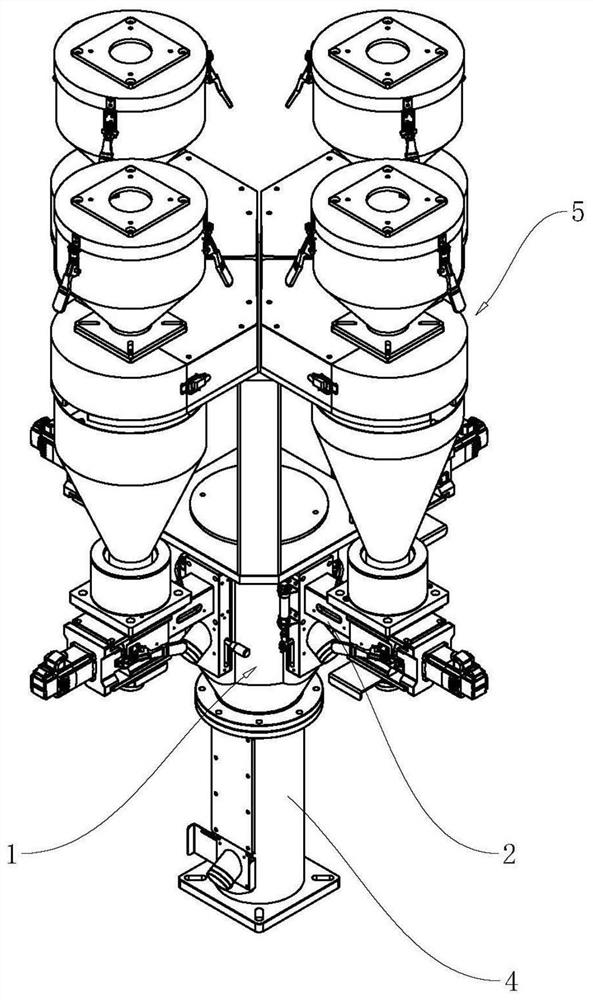

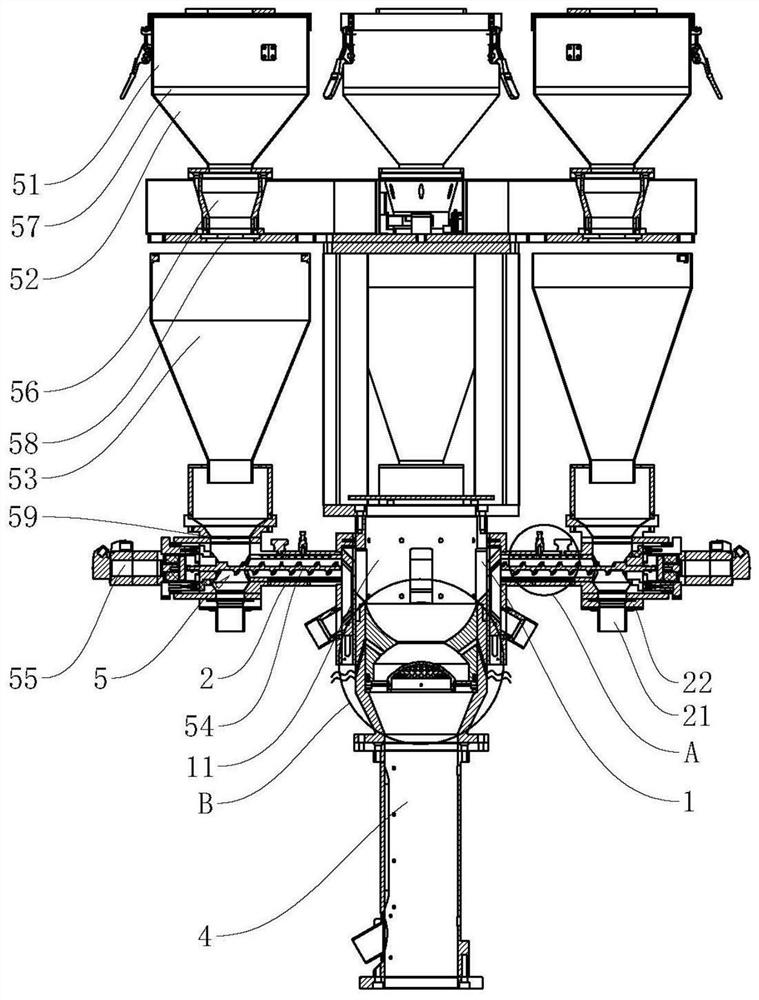

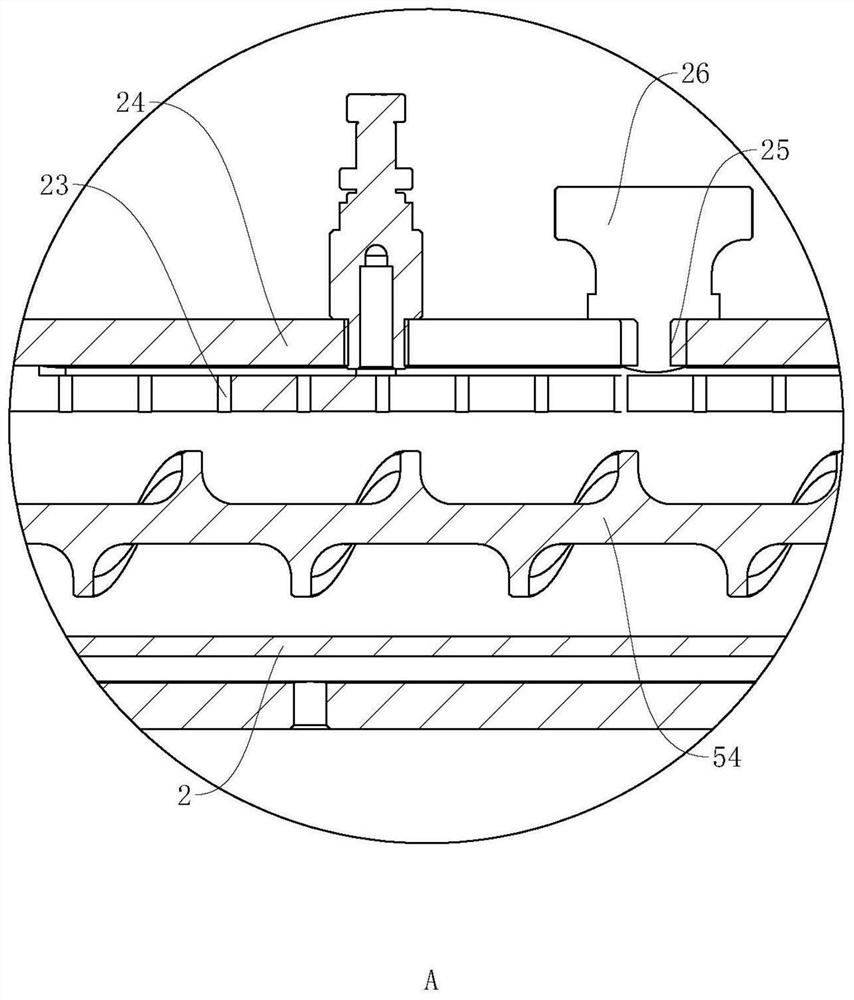

[0035] The following is attached Figure 1-4 The application is described in further detail.

[0036] The embodiment of the present application discloses an automatic feeding and color matching machine. refer to figure 1 with figure 2 , this kind of automatic feeding color matching machine includes a main mixing chamber 1, a main mixing chamber 11 is arranged in the main mixing chamber 1, and a plurality of feeding pipes 2 are arranged in communication with the main mixing chamber 11, and its characteristics In that: the main mixing chamber 1 is provided with a material distribution structure 3, and the bottom of the main mixing chamber 1 is connected with a storage bin 4, and the material flows into the main mixing chamber 11 through a plurality of the feeding pipes 2 In the main mixing chamber 11, the materials are mixed by the distribution structure 3 and then flow into the storage bin 4.

[0037] refer to figure 1 with figure 2 , there are at least four feed pipes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com