A blade-adjustable atomizing nozzle

An atomizing nozzle and adjustable technology, applied in fire rescue and other directions, can solve the problems of large loss of compressed gas, damage to protected objects, insufficient atomization degree of electrical equipment, etc., and achieve the effect of increasing the spraying distance and reducing the loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

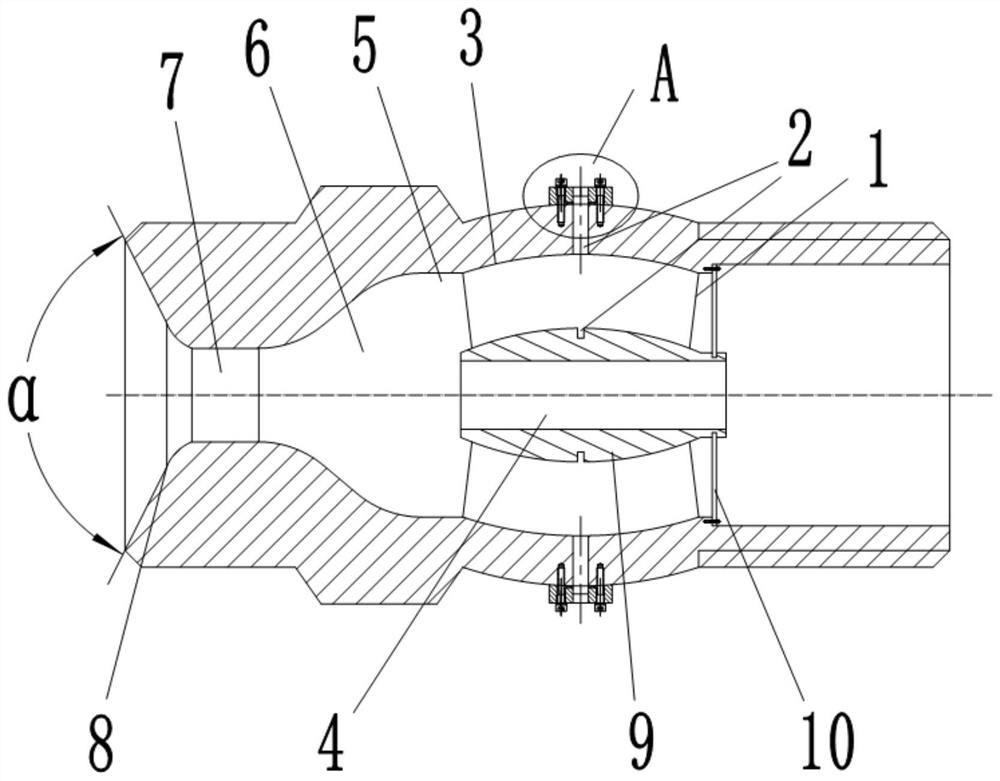

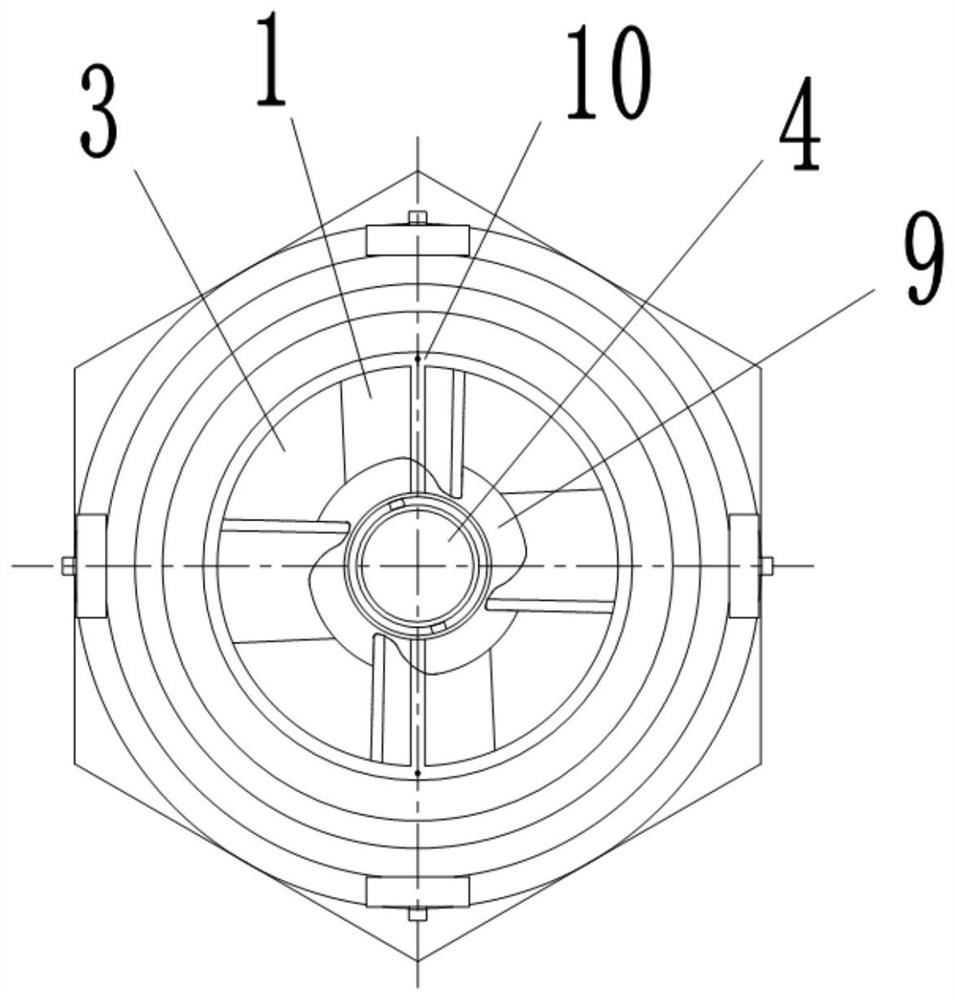

[0034] Append figure 1 Addition Image 6 As shown, a blade can be adjusted atomized nozzle, including a spray head housing, an inlet, a swirling chamber 3, and a water outlet, inlet and a swirl cavity 3, and in the swirl cavity 3 Isolation 9;

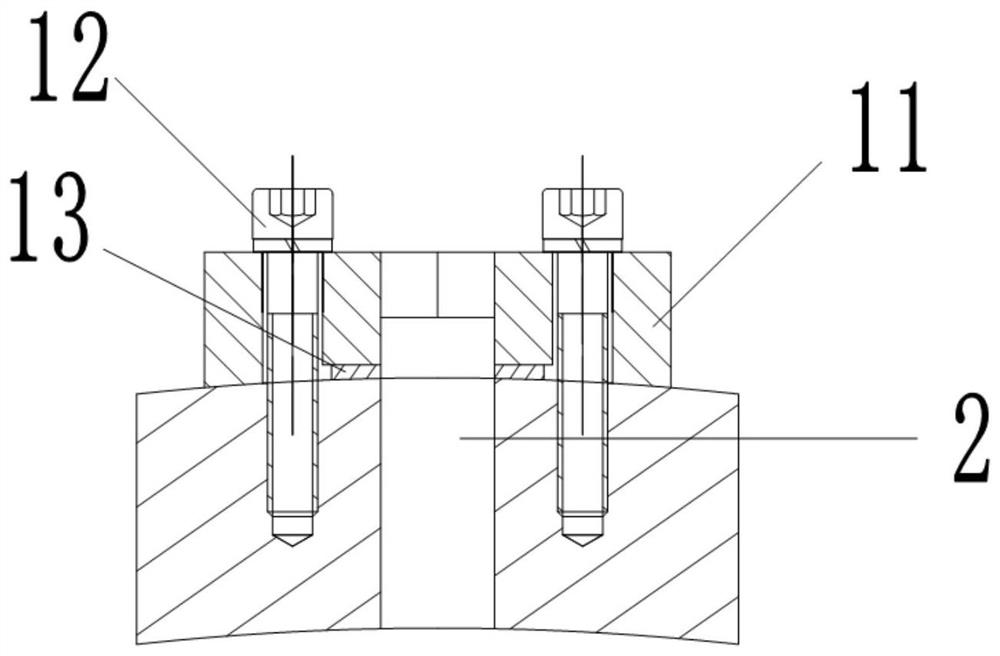

[0035] A plurality of twisted blades 1 are provided in the swirl chamber 3, and the twisted blades 1 feed edges are 15 mm from the air inlet inlet, and the twisting blade 1 is fixedly disposed, and the center rotation shaft 2 is inserted, the center rotation shaft 2 is inserted into the separator 9, the other end Pass through the spray head housing and the adjustment mechanism is connected.

[0036] The swirl chassis 1 is provided in the swirl chamber 3, and the fluid is formed to form a high speed swirl after the fluid passes through the swirling chamber 3, and since the action of the centrifugal force is atomized, the spray enlarged injection range is formed, and the twist blade 1 provides fluid to the fluid provides rotational performance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com