A Single Controller and Detection Algorithm for an Electric-driven Corn Precision Seeder

A detection algorithm and controller technology, which is applied in the field of agricultural machinery, can solve the problems of low function integration, unfavorable expansion of the number of lines, and high cost, and achieve the effect of alleviating the pressure of information processing, facilitating the expansion of the number of lines, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038]The present invention will be further described in detail below in conjunction with the accompanying drawings.

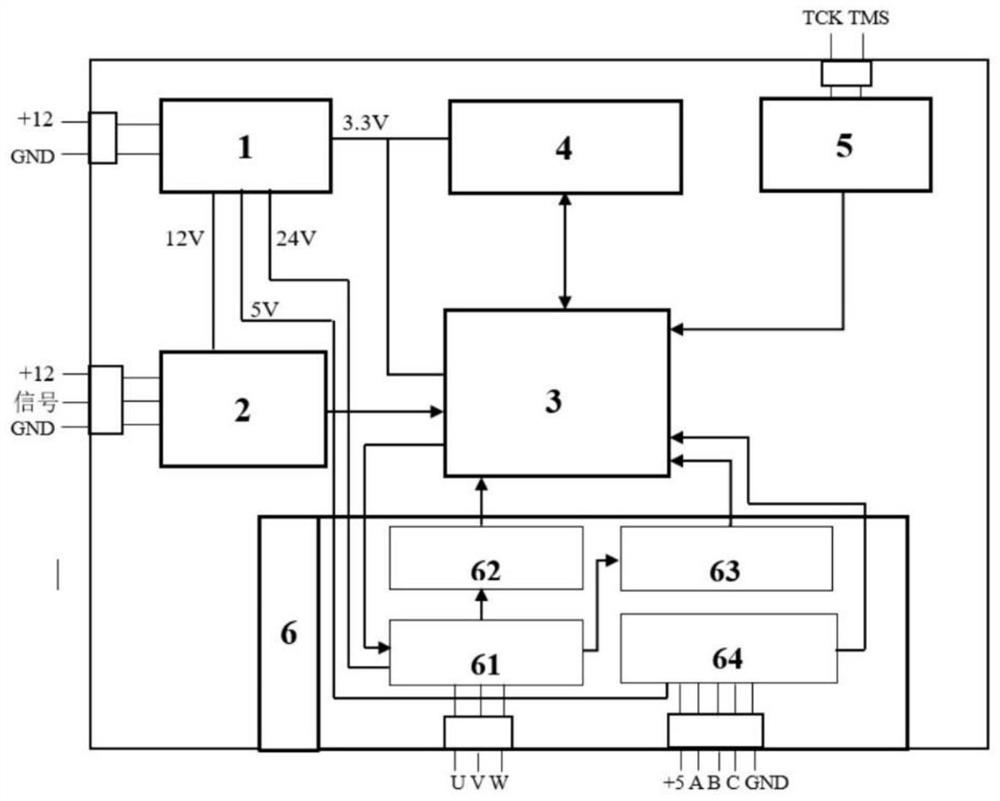

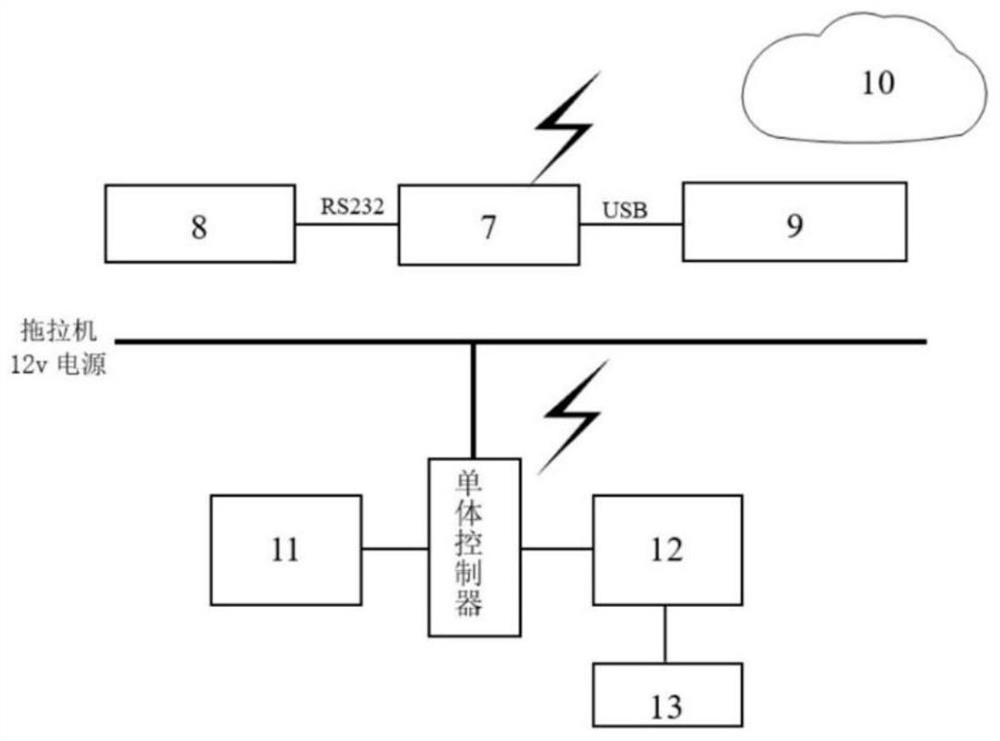

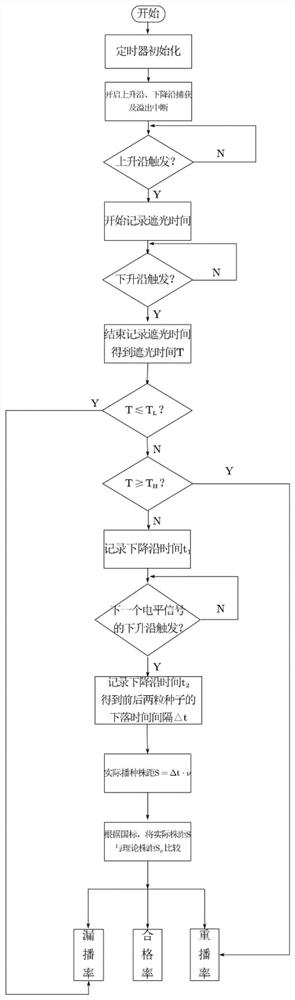

[0039] Such as figure 1 In the shown embodiment of the present invention, the single controller is composed of a power supply circuit 1, an STM32 minimum system circuit 3, a motor drive circuit 6, a seeding quality monitoring circuit 2, a Zigbee communication circuit 4, and a program debugging circuit 5; wherein the power supply circuit 1 The input end is connected with the tractor 12v storage battery, and the power supply circuit 1 is provided with four output ends of 12v output, 24v output, 5v output and 3.3v output to supply power for each circuit; wherein the 12v output is connected with the sowing quality monitoring circuit 2, and the 24v output is connected with the sowing quality monitoring circuit 2 The full-bridge drive circuit 61 of the motor drive circuit 6 is connected, the 3.3v output is connected with the Zigbee communication circuit 4 , and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com