Troubleshooting analysis method of aircraft system

An analysis method and aircraft system technology, applied in the field of aviation, can solve problems such as lack of normative standards for troubleshooting analysis methods, achieve the effect of saving troubleshooting time and cost, and improving troubleshooting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

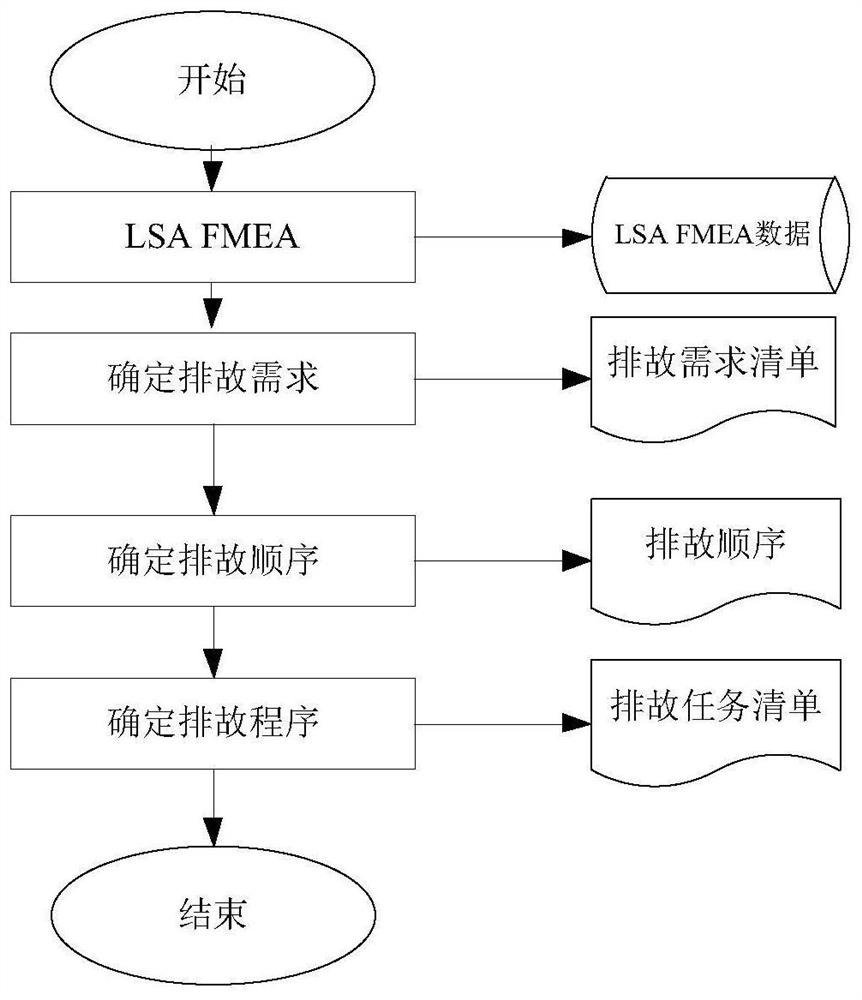

[0069] Step 1: Conduct LSA FMEA

[0070] One LSA FMEA failure mode integration table for each replaceable unit

[0071] Table A1 LSA FMEA failure mode integration table

[0072]

[0073]

[0074]

[0075]

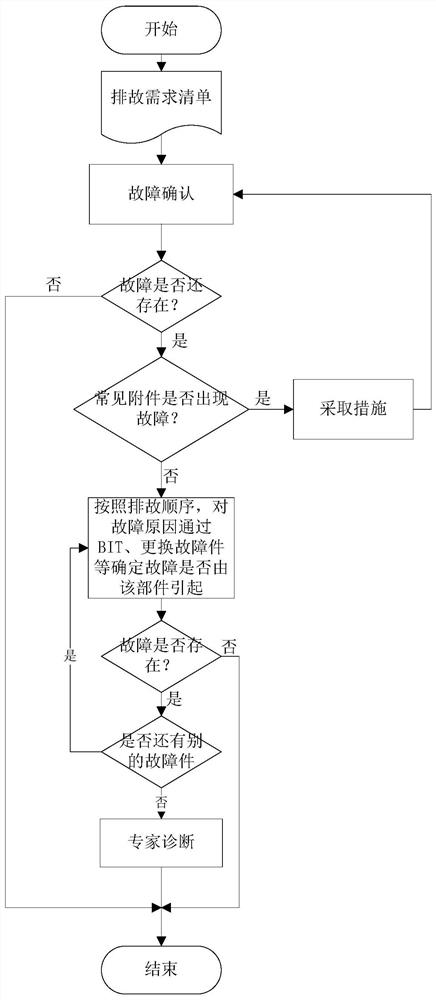

[0076] Step Two: Determine Troubleshooting Needs

[0077] According to the fault mode integration table, the indication / observation faults in the detection method are extracted in different LRUs as troubleshooting requirements.

[0078] Table A2 Fault Fuzzy Group Table List

[0079]

[0080] Step Three: Determine the Troubleshooting Sequence

[0081] According to the failure rate λ1=0.82, λ2=0.22 in the failure mode integration table, the troubleshooting time of the deicing controller is T1=0.5h, and the troubleshooting time of the heating automatic drain valve is T2=0.3h. See the table below for the order of calculation and troubleshooting:

[0082] Table A3 Fault Isolation Sequence Policy

[0083]

[0084] Select scheme 1 with the lowest total mean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com