Static elimination monitoring equipment and monitoring method

A technology for monitoring equipment and static electricity elimination, which is applied to structural parts of electrical equipment, static electricity, electrical equipment shells/cabinets/drawers, etc., which can solve the problems affecting the service life of monitoring equipment, the heat of monitoring equipment is not easy to dissipate, and the monitoring effect is not good. problem, achieve the effect of preventing accidental rotation, preventing excessive temperature and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

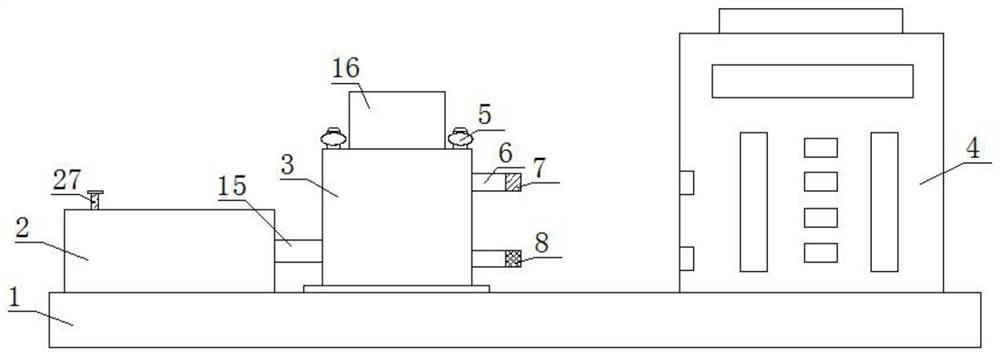

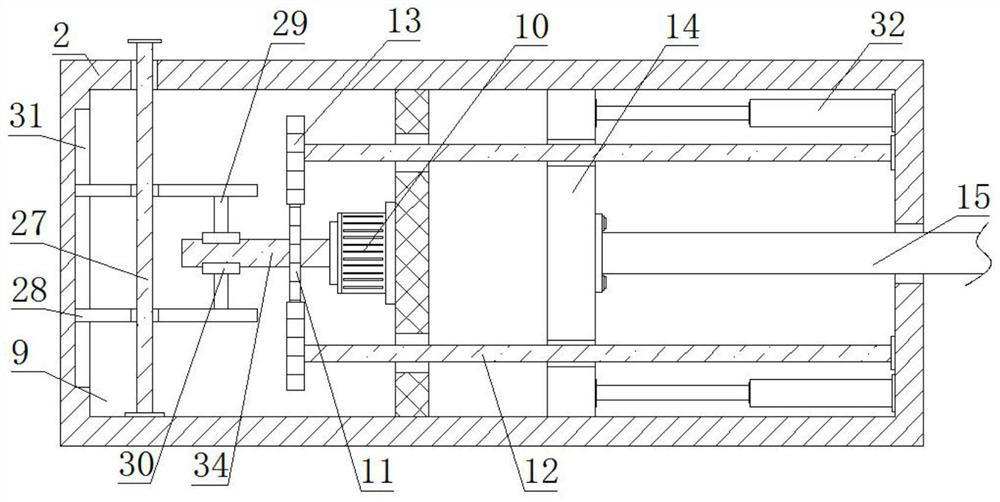

[0031] refer to Figure 1-5 In this embodiment, a static elimination monitoring device is proposed, including a base 1, the top of the base 1 is fixedly connected with a fixed seat 2 and a static elimination device 4, and the top of the base 1 is slidably connected with a monitoring device main body 3, and the monitoring device main body 3 is located between the fixed seat 2 and the static elimination device 4, the fixed seat 2 is provided with a fixed chamber 9, the fixed chamber 9 is fixedly connected with a fixed plate, one side of the fixed plate is fixedly connected with a first motor 10, the first The output shaft of the motor 10 is fixedly connected with a driving shaft 34, the driving shaft 34 is fixedly sleeved with a driving gear 11, and the inner wall of one side of the fixed chamber 9 is symmetrically rotated and connected with two threaded shafts 12, the two threaded shafts 12 One end runs through the fixed plate and extends to one side of the fixed plate. One end...

Embodiment 2

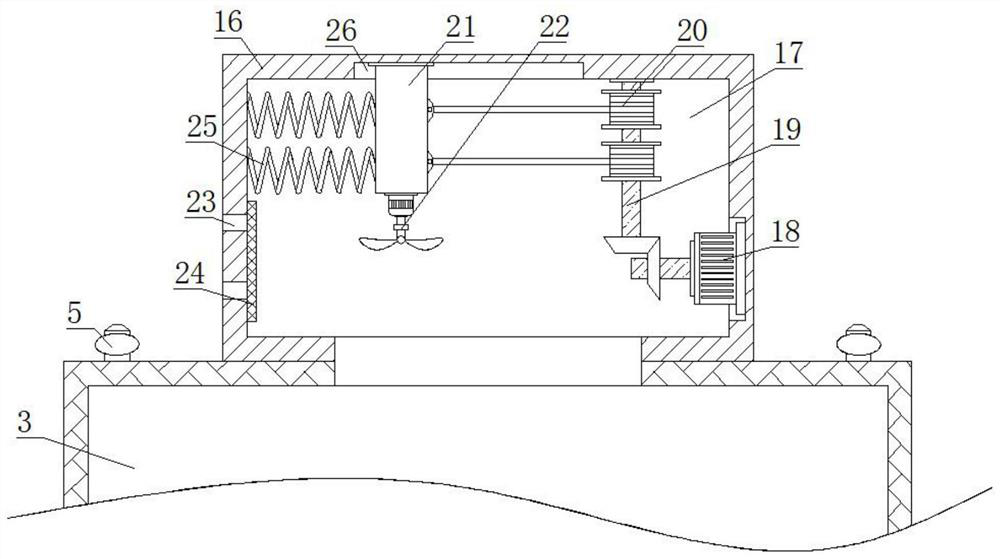

[0033] In this embodiment, the heat dissipation assembly includes an installation chamber 17 arranged on a rectangular seat 16, a groove is opened on one side of the inner wall of the installation chamber 17, and a second motor 18 is fixedly connected to one side of the inner wall of the groove. The top inner wall of the chamber 17 is rotatably connected with a connecting shaft 19, and the bottom end of the connecting shaft 19 and the output shaft of the second motor 18 are fixedly sleeved with bevel gears, and the two bevel gears are meshed, and the connecting shaft 19 is symmetrical. The fixed sleeve is provided with two reels 20, and a connecting rope is wound around the two reels 20. A sliding plate 21 is slidably connected to the inner wall of the top of the installation chamber 17, and a cooling fan is fixedly connected to the bottom of the sliding plate 21. 22. One end of the two connecting ropes is fixedly connected to one side of the sliding plate 21, the top of the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com