Measuring method for correcting reference point coordinates based on thermal expansion coefficient

A technology of thermal expansion coefficient and measurement method, applied in measurement devices, instruments, etc., can solve the problems of inaccurate measurement results, theoretical reference point deviation, etc., to reduce measurement errors, reduce fitting errors, and make measurement results more realistic and reliable. letter effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] As the basic embodiment of the present invention, the present invention includes a method of measuring the coordinates of the reference point based on thermal expansion coefficient correction, including the following steps:

[0023] a. Determine the origin of the coordinates: establish a measurement coordinate system, and use the point G of the center of gravity of the part as the origin (0,0,0) of the measurement coordinate system.

[0024] b. Conversion of the original reference point coordinates: according to the coordinates of the center of gravity position G point on the actual part, a series of original reference point coordinates on the part are converted into coordinate points relative to the center of gravity position G point in the measurement coordinate system, the original The reference point A is (x, y, z).

[0025] c. Correction of reference point coordinates: After demoulding, the original reference point A (x, y, z) becomes the correction reference point...

Embodiment 2

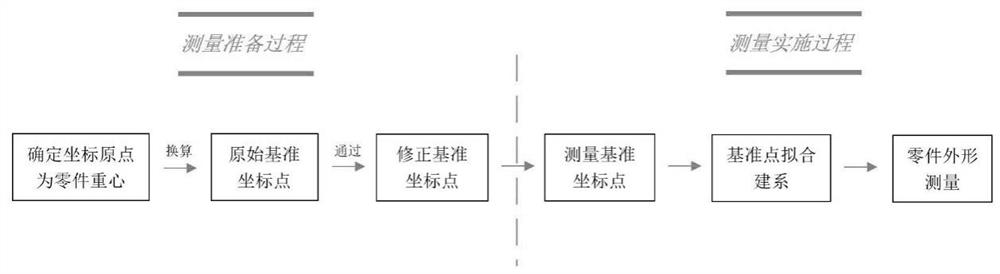

[0031] As the best implementation mode of the present invention, with reference to the attached figure 1 , the present invention includes a measurement method for correcting reference point coordinates based on coefficient of thermal expansion, including a measurement preparation process and a measurement implementation process. The measurement preparation process includes: determining the coordinate origin as the center of gravity of the part, converting the coordinates of the original reference point, and correcting the coordinates of the reference point. The measurement implementation process includes: measuring the coordinates of the actual reference point, fitting the reference point and establishing a system, and measuring the shape of the part.

[0032] The measurement method specifically includes the following steps:

[0033] a. Determine the coordinate origin: establish a measurement coordinate system, and use the center of gravity position G on the part as the origi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com