Automatic hot melting device for novel material and working method of automatic hot melting device

A new material, hot-melt technology, applied in the field of building material production, can solve the problems of low degree of automation and waste of manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

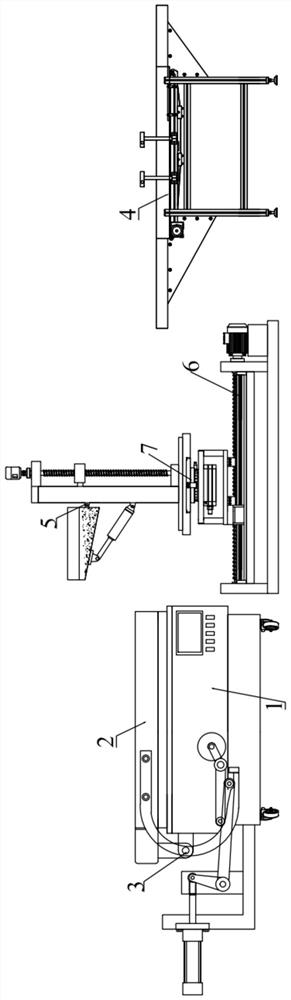

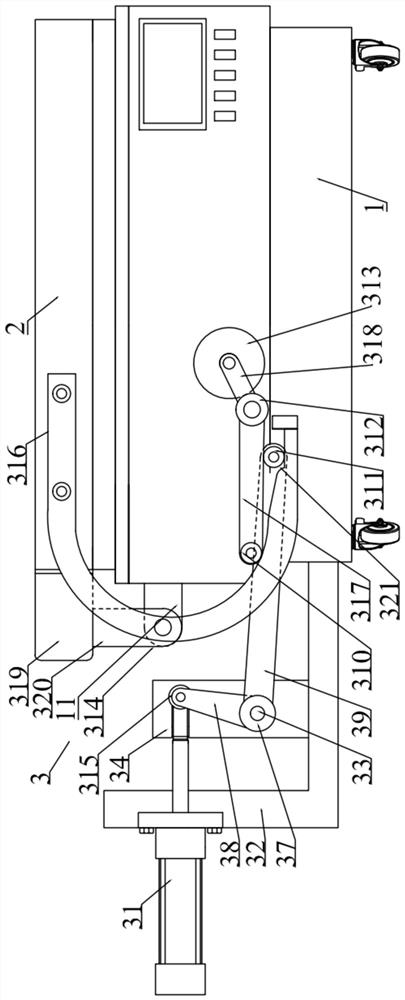

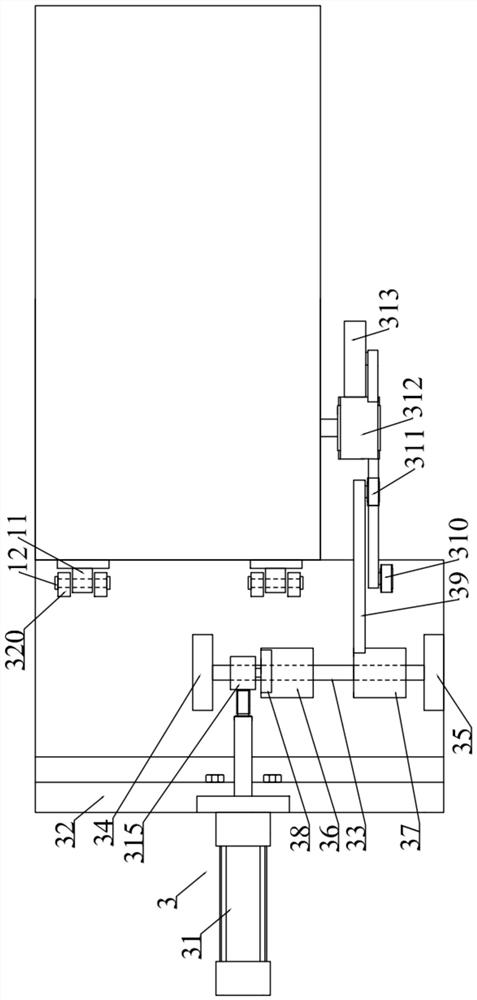

[0046] like figure 1 The shown automatic hot-melting equipment for new materials includes a hot-melting machine body 1, a hot-melting machine upper cover 2, a hot-melting machine automatic flip device 3, a raw material feeding device 4, a raw material transfer device 5, a transfer horizontal drive device 6 and a transfer device. Rotation drive device 7, the hot-melt machine automatic flip device 3 is arranged on the hot-melt machine body 1, and the hot-melt machine automatic flip device 3 is connected to the hot-melt machine upper cover 2, and the hot-melt machine upper cover 2 is covered in the hot-melt machine. At the opening of the upper end of the melter body 1, the raw material feeding device 4 and the transfer rotary drive device 7 are both located on one side of the hot melt machine body 1, and the transfer rotary drive device 7 is located at the raw material feeding device 4 and the hot melt machine body. 1, the transporting horizontal driving device 6 is set on the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com