Scaffold connecting device for civil engineering

A connecting device and scaffolding technology, which is applied in the connection of scaffolding, construction, building construction, etc., can solve problems such as poor stability and safety, poor safety and stability, and complicated connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

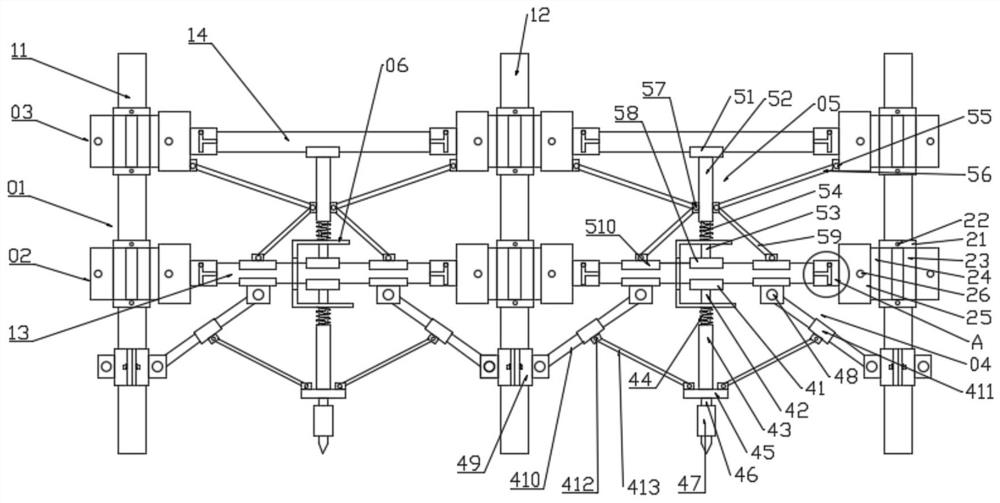

[0026] see Figure 1~5 , in an embodiment of the present invention, a scaffold connection device for civil engineering, including a frame body 01, the frame body 01 includes a first vertical bar 11, a second vertical bar 12, a first cross bar 13 and a second cross bar 14, wherein the first A cross bar 13 and a second cross bar 14 are arranged between the first vertical bar 11 and the second vertical bar 12 for connecting and supporting, and the first cross bar 13 is arranged below the second cross bar 14; The first cross bar 13 and the second cross bar 14 are respectively connected with the first vertical bar 11 and the second vertical bar 12 through the first connection assembly 02 and the second connection assembly 03, and then the first vertical bar 11 and the second vertical bar 12 are connected together, so that the first vertical bar 11 and the second vertical bar 12 have very good stability, and at the same time, it is convenient to install and disassemble. The structur...

Embodiment 2

[0035] The connecting plate 06 includes a first through hole 61 and a second through hole 62, wherein the first through hole 61 is inserted into the first cross bar 13, and the number of the second through hole 62 is two, which are respectively connected with the second fixing rod 53 and the first The fixed rod 42 is connected, and then the bottom connection assembly 04 and the middle connection assembly 05 can be connected together, so that the overall stability is higher.

[0036] The working principle of the present invention is: first adjust the distance between the first vertical bar 11 and the second vertical bar 12 as required, and then install the first cross bar 13 on the first vertical bar 11 and the second vertical bar 12 through the first connection assembly 02 Between the vertical bars 12, the whole is fixed on the ground by the bottom connection assembly 04, and then the middle connection assembly 05 is installed on the top of the first cross bar 13, and then the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com