Automatic leveling system and method suitable for steel pipe column working platform

A working platform and automatic leveling technology, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of slow leveling speed and different levels of consideration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

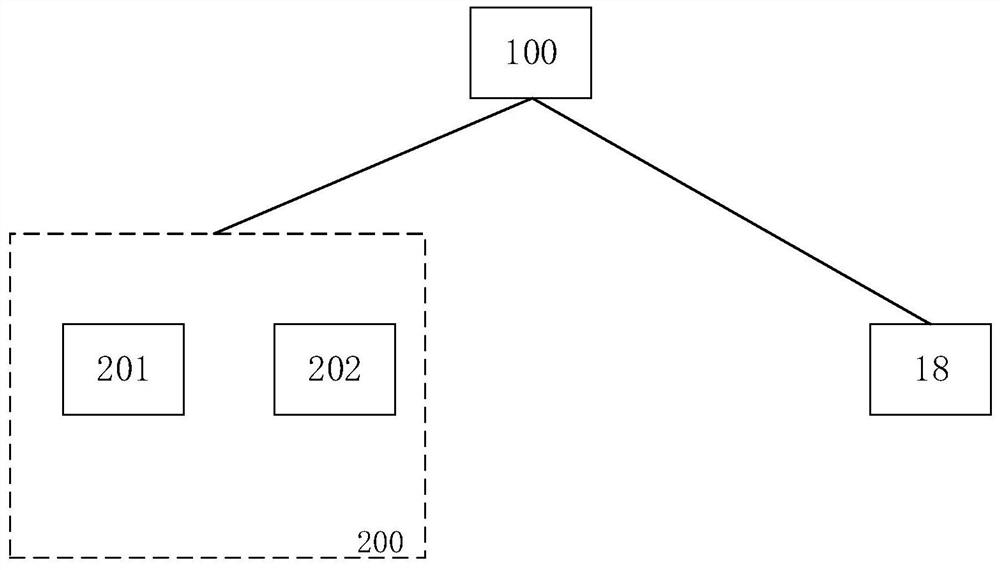

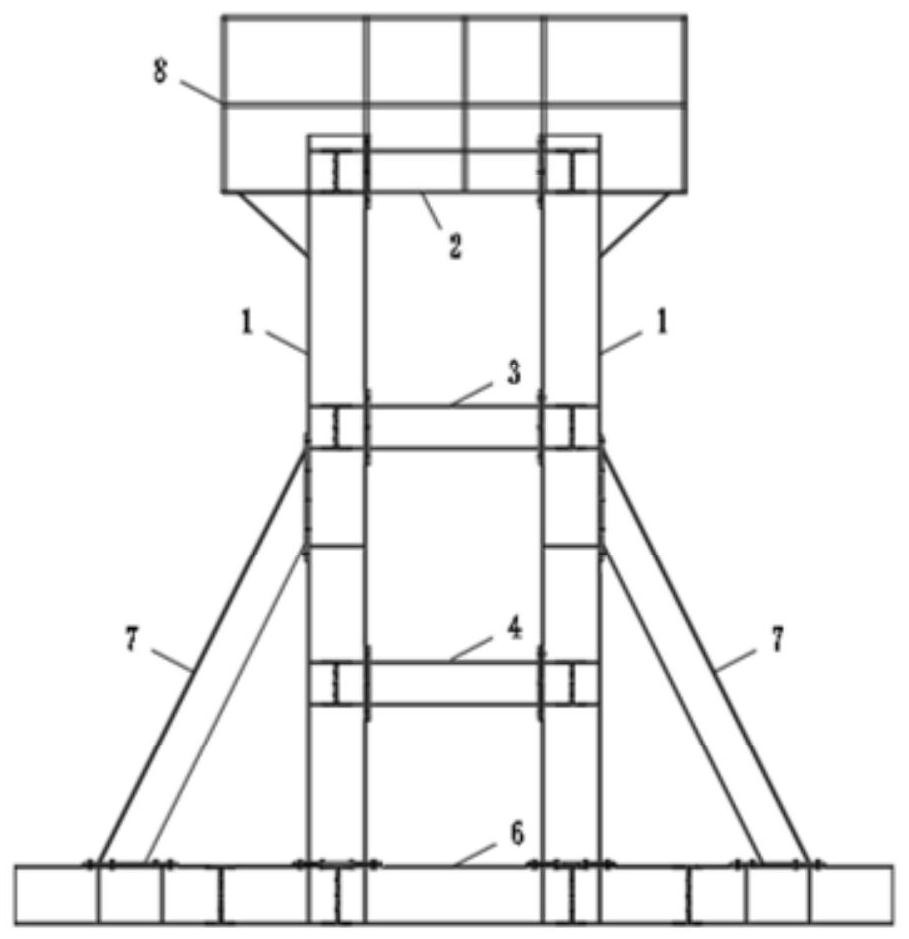

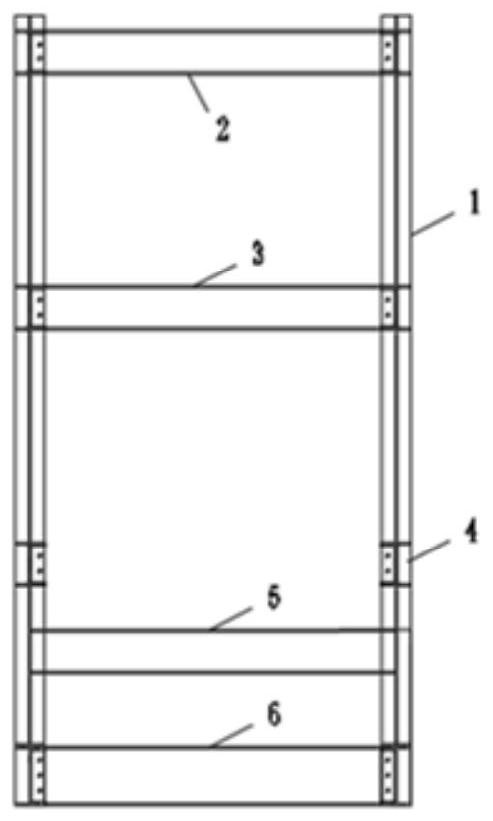

[0063] Such as figure 1 As shown, the present invention provides an automatic leveling system suitable for a steel pipe column working platform. The system comprises a control device 100 , a level monitoring device 200 and a leveling device 18 . The level monitoring device 200 includes a first level monitor 201 and a second level monitor 202 . The first level monitor 201 is used for monitoring the level of the first direction. The second level monitor 202 is used for monitoring the level of the second direction. The first direction may be the direction in which the length of the frame body 16 extends. The first direction and the second direction are perpendicular to each other. Preferably, the fourth cross brace 17 is perpendicular to the frame body 16 . The second direction may be the direction in which the length of the fourth cross brace 17 extends. Preferably, the first level monitor 201 is disposed at the frame body 16 . The second horizontal monitor 202 is dispose...

Embodiment 2

[0072] This embodiment is a further improvement / supplement to Embodiment 1, and repeated content will not be repeated.

[0073] In the leveling process of Embodiment 1, after leveling the first direction / second direction of the working platform, it still needs to be re-measured by the level monitoring device 200 to verify whether the level of the working platform meets the requirements. However, in actual engineering construction, the condition of the natural floor is complicated, and factors such as the flatness of the ground and the degree of hardening may cause the horizontal deviation of the first direction / second direction of the working platform to change again, so it is still necessary to repeatedly monitor the horizontal deviation Level and adjust the degree of horizontal deviation through the leveling device 18, and then if you want to meet the construction accuracy requirements, you still need a lot of time for leveling. Based on this problem, this embodiment improve...

Embodiment 3

[0086] This embodiment is a further improvement / supplement to Embodiments 1 and 2, and repeated content will not be repeated.

[0087] Further, the control device 100 is configured to control at least one leveling device 18 in a time-sharing and asynchronous manner to adjust the horizontal deviation degrees of the base 6 in the first direction and the second direction respectively. This process is a rough adjustment process, which may result in a relatively large leveling range of the leveling device 18 . On the one hand, although the vertical body 301 is equipped with a counterweight body 3012 to reduce shaking, the large leveling range may still cause the vertical body 301 to swing repeatedly, and cannot be in a natural vertical state quickly. On the other hand, the large leveling range results in that the light emitted by the light emitting element 3013 of the vertical body 301 cannot be aligned with the first optical element 3021 on the photosensitive area 302 in a short t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com