Efficient textile dedusting and disinfecting device

A technology for disinfection devices and textiles, applied in the field of textiles, can solve problems such as the occurrence of peculiar smell in textiles and disinfection devices, and achieve the effects of improving disinfection efficiency, ensuring a normal disinfection environment, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

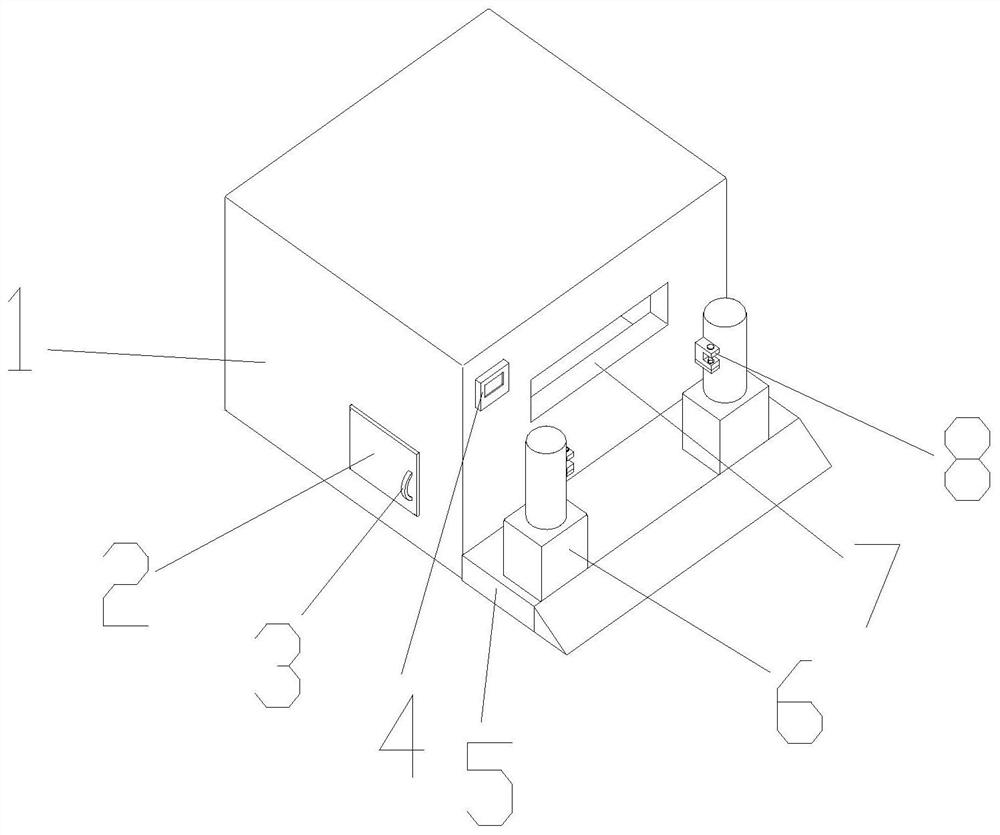

[0035] like Figure 1-2 , the present invention provides a technical solution: a high-efficiency dedusting and disinfection device for textiles, comprising a box body 1, the front middle part of the box body 1 is provided with a feeding port 7, and the front side of the box body 1 is located at the upper left side of the side of the feeding port 7 The controller 4 is fixedly connected, the front bottom of the box body 1 is fixedly connected with the bottom plate 5, the top and both sides of the bottom plate 5 are fixedly connected with the feeder 6, and the top of the feeder 6 is fixedly connected with the U Type clamping block 8, the left bottom position of box body 1 is provided with box door 2 near the position of bottom plate 5, and the front right middle part position of box door 2 is fixedly connected with handle 3.

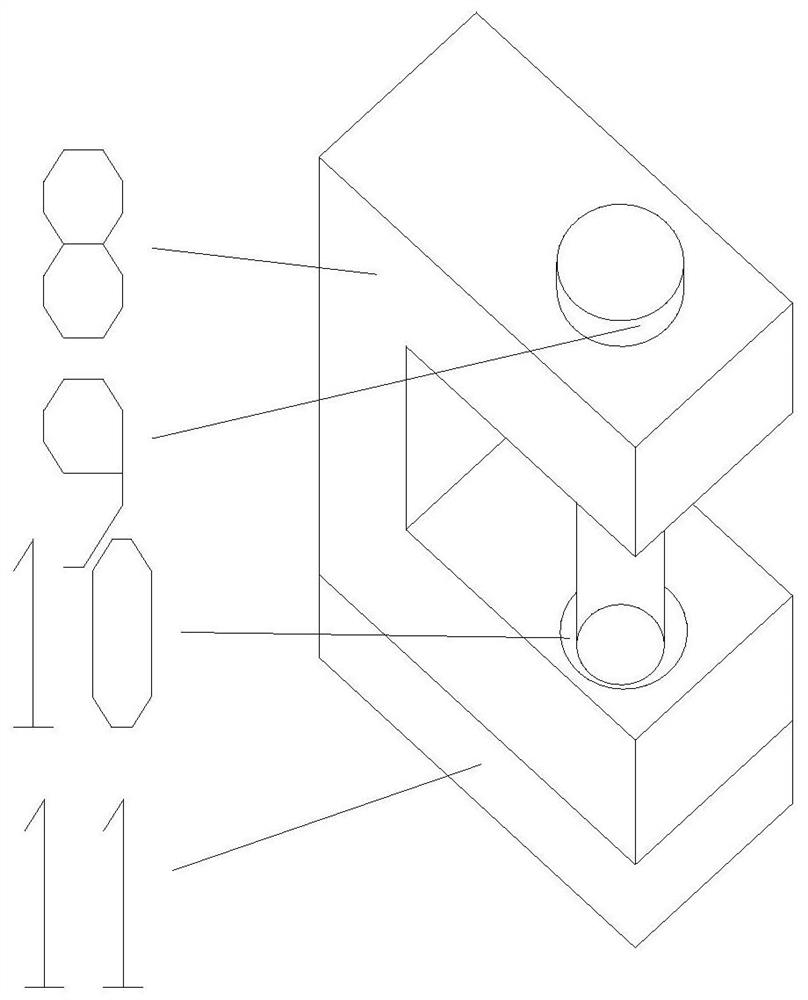

[0036] Wherein, the bottom of the U-shaped clamping block 8 is fixedly connected with the limit block 11, and the top of the U-shaped clamping block 8 is p...

Embodiment 2

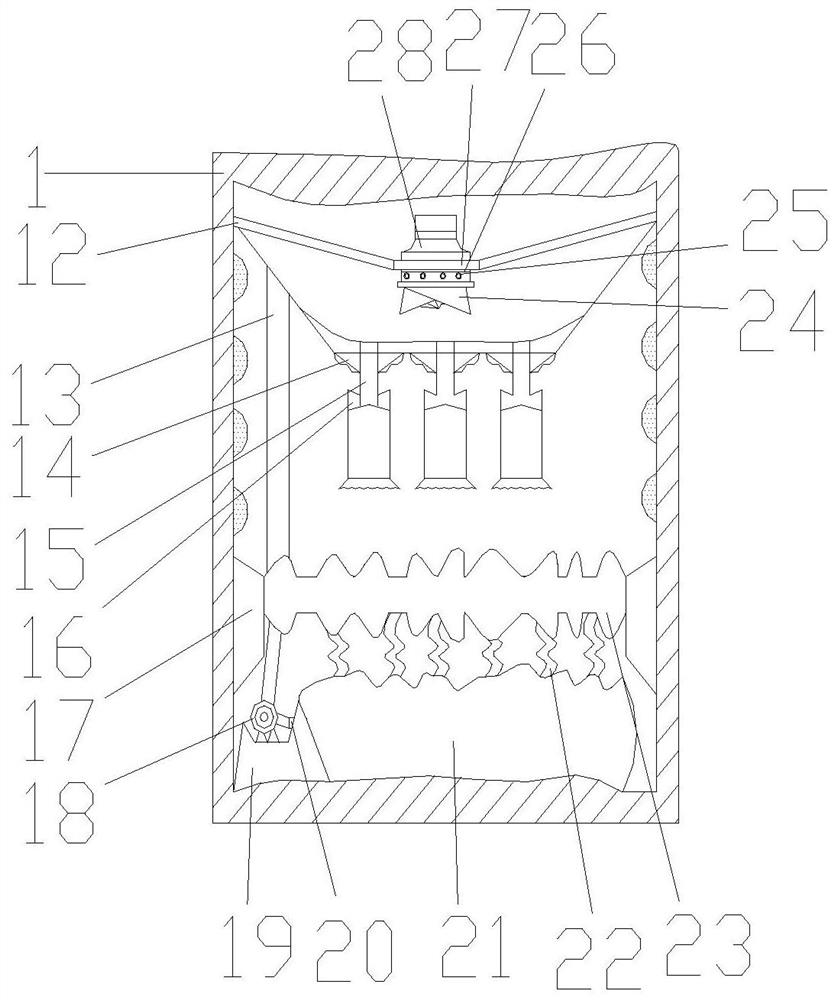

[0039] like Figure 1-3 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: a transition box 12 is fixedly connected to the top of the inner wall on both sides of the box body 1, and a delivery pipe 13 is arranged on the left side of the bottom of the transition box 12, and the transition box 12 The top middle position of the top is fixedly connected with a connecting piece 27, and the bottom of the connecting piece 27 is fixedly connected with a feeding tray 24, and the connecting piece 27 is provided with a sealing ring 26 between the feeding trays 24, and the top outer surface of the feeding tray 24 is provided with a fixed The screw 25 and the top of the connector 27 are fixedly connected with the bearing 28, the top of the bearing 28 communicates with the conveying pipe 13, the bottom of the transition box 12 communicates with the telescopic vacuum cleaner 15, and the bottom of the transition box 12 is located on both sides of the tel...

Embodiment 3

[0042] like Figure 1-5 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the top of the back of the inner cavity of the box body 1 is provided with a vent 29, and the inside of the vent 29 is provided with a cooling fan 30, and the box body The inner walls on both sides of 1 are located below the vent 29 and are fixedly connected with a fixed frame 31, and the side of the fixed frame 31 away from the vent 29 is fixedly connected with a disinfection device 32, and the middle position of the back of the inner cavity of the box body 1 is provided with a discharge port 33 The inner walls on both sides of the box body 1 are fixedly connected with a sealing layer 34 under the fixed frame 31, the bottom of the inner cavity of the box body 1 is fixedly connected with a support seat 36, and the top of the support seat 36 is fixedly connected with a balloon removal layer 35.

[0043] Wherein, the disinfection device 32 compris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com