Novel OLED screen protective film and preparation method and application thereof

A technology of screen protection film and protective film, which is applied in the direction of adhesive type, film/sheet release liner, film/sheet adhesive, etc., which can solve the strict requirements of static electricity, lack of OLED display protective film, etc. Problems, to achieve the effect of low static voltage of tear film, excellent exhaust, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

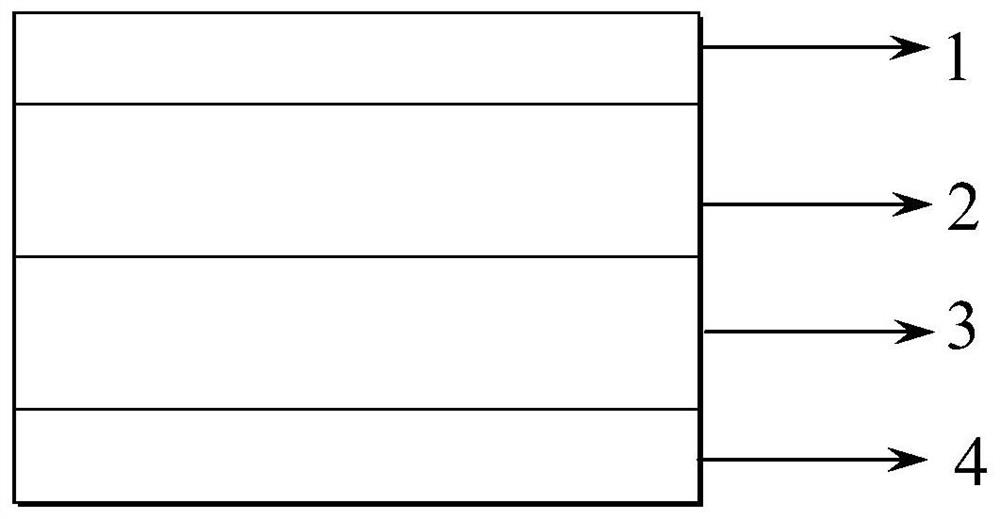

Image

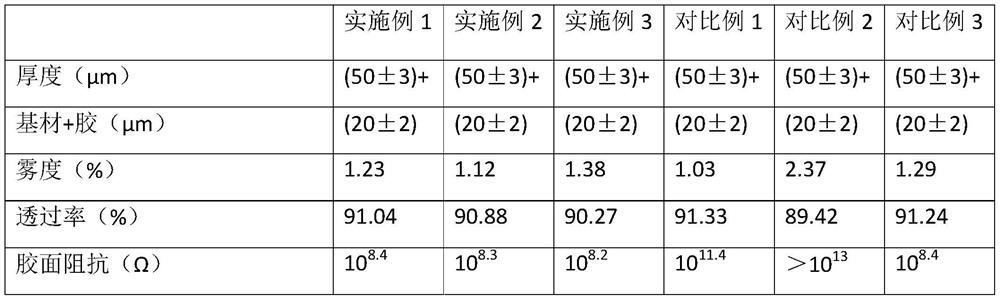

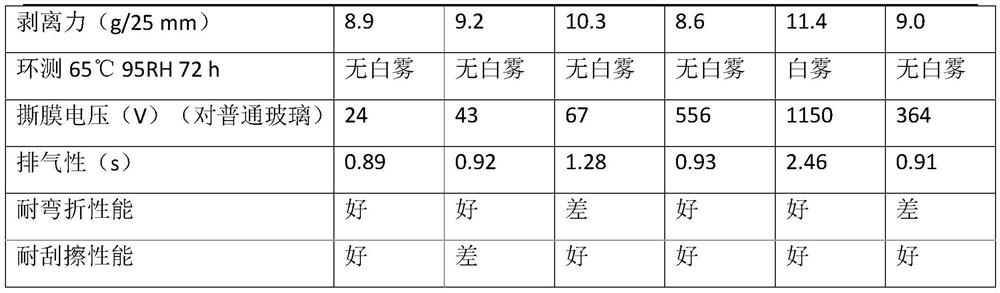

Examples

Embodiment 1

[0033] S1. The hardness of TPU is set to 45-50HD, and anti-ultraviolet and anti-static TPU film is used;

[0034] S2. The production process of the thermosetting TPU layer is the slit coating method, the speed of the vehicle is 20m / min, the drying temperature of the coating machine oven is set at 55-105°C, and 6 baking stages are set in sequence during the drying process. Section 55°C, 75°C, 95°C, 105°C, 95°C, 75°C;

[0035] S3, remove the release film of one side of TPU, and apply hardening solution;

[0036] S4. The production process of the hardened layer is the coating method, the vehicle speed is 25m / min, the drying temperature of the front oven is set at 60-110°C, and the drying process is set with 4 baking sections of 65°C, 80°C, 95°C, and 105°C , the back-end UV curing energy is set to 480mj / cm 2 ;The thickness of the hardened layer is 2-5μm, and the hardness of the hardened layer is greater than 3H;

[0037] S5, remove the release film on the other side of the TPU,...

Embodiment 2

[0042] S1. The hardness of TPU is set to 45-50HD, and anti-ultraviolet and anti-static TPU film is used;

[0043] S2. The production process of the thermosetting TPU layer is the slit coating method, the speed of the vehicle is 20m / min, the drying temperature of the coating machine oven is set at 55-105°C, and 6 baking stages are set in sequence during the drying process. Section 55°C, 75°C, 95°C, 105°C, 95°C, 75°C;

[0044]S3, remove the release film on one side of TPU, use TPU as the coating base material, and coat PU glue;

[0045] S4. The production process of PU glue is the coating method, the speed of the vehicle is 21m / min, the drying temperature of the coating machine oven is set at 85-135°C, and six baking sections of 85°C and 105°C are set in turn during the drying process. ℃, 125℃, 135℃, 125℃, 105℃;

[0046] S5. The release film bonded with PU glue is an antistatic release film;

[0047] S6. After the sample is completed, it needs to be aged at 80°C for 24 hours....

Embodiment 3

[0049] S1. Adjust the hardness of the TPU layer to 90HD, and use anti-ultraviolet and anti-static TPU film;

[0050] S2. The production process of the thermosetting TPU layer is the slit coating method, the speed of the vehicle is 20m / min, the drying temperature of the coating machine oven is set at 55-105°C, and 6 baking stages are set in sequence during the drying process. Section 55°C, 75°C, 95°C, 105°C, 95°C, 75°C;

[0051] S3, remove the release film of one side of TPU, and apply hardening solution;

[0052] S4. The production process of the hardened layer is the coating method, the vehicle speed is 25m / min, the drying temperature of the front oven is set at 60-110°C, and the drying process is set with 4 baking sections of 65°C, 80°C, 95°C, and 105°C , the back-end UV curing energy is set to 480mj / cm 2 ;The thickness of the hardened layer is 2-5μm, and the hardness of the hardened layer is greater than 3H;

[0053] S5, remove the release film on the other side of the T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com