Gate type sliding hoisting support

A sliding and hoisting technology, which is used in hoisting devices, transportation and packaging, load hoisting components, etc., can solve the problems of large relative drop, cumbersome transfer steps, hidden safety hazards, complex building roof elevations, etc., and achieve the effect of simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

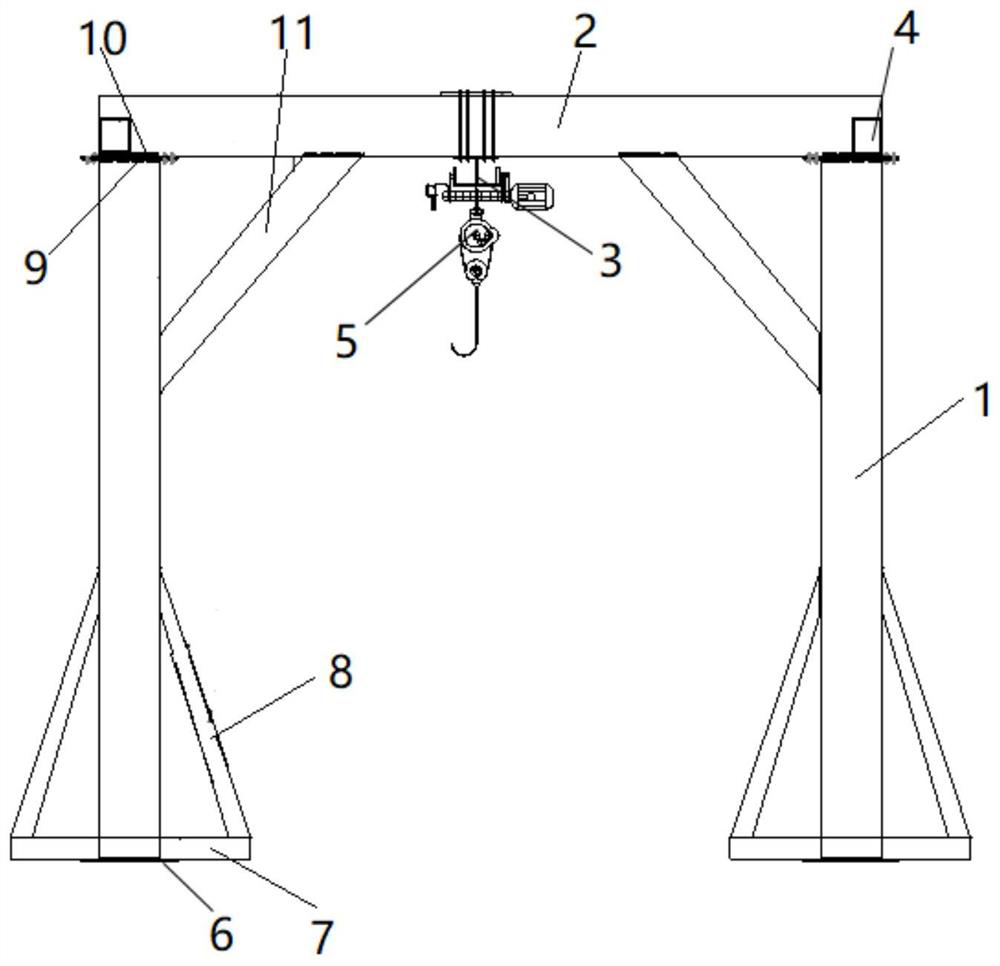

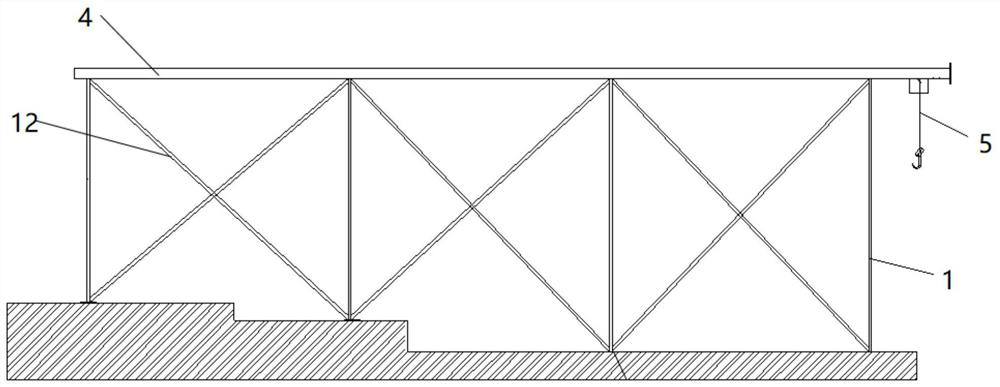

[0018] A door-type sliding lifting bracket in this embodiment includes a plurality of columns 1; the columns 1 are arranged in two rows and arranged in pairs; The arrangement direction is set and connected with the bottom of each beam 2; the electric hoist 5 with pulleys is slidably arranged on the lower flange plate of the I-beam 3 along the extension direction of the I-beam 3 .

[0019] The structure of the door-type sliding hoisting bracket of this embodiment is simple, safe and reliable. After the column 1 is set up in the hoisting area, the hoisting position can be adjusted through the electric hoist 5 with pulleys. Meet the material transfer requirements of roofs with different elevations.

[0020] As a preferred embodiment, in the door-type sliding hoisting bracket, a base 6 is provided at the bottom of the column 1 . The base 6 can be a steel plate welded on the bottom of the column 1, which is used to increase the contact area between the door type sliding lifting br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com