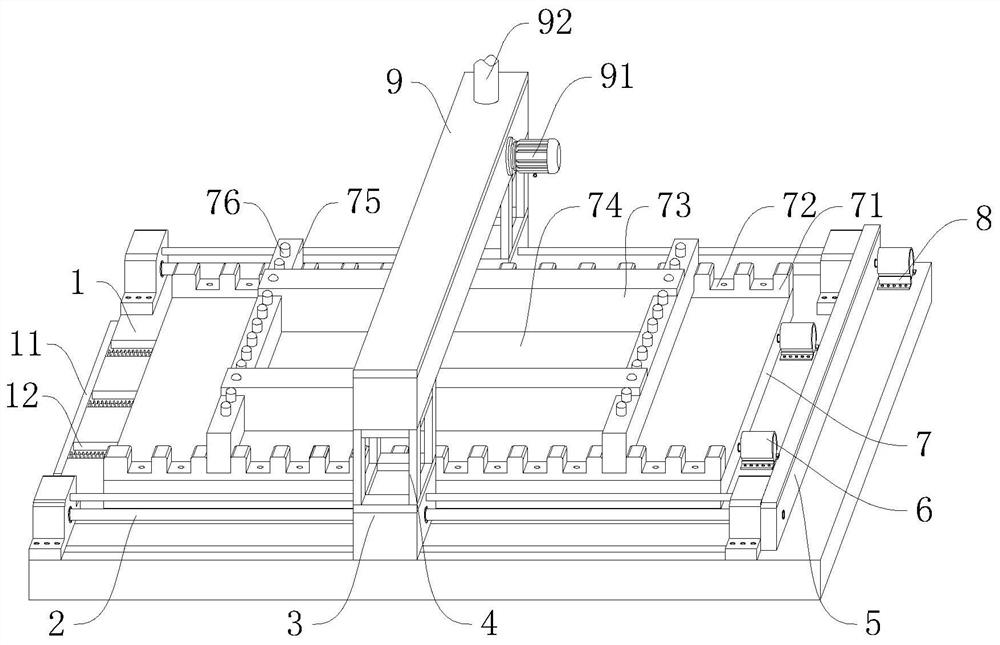

An integrated concrete pouring and vibrating machine for composite floor slabs of an assembled integral building

A technology for laminated slabs and concrete, which is applied in the direction of supply devices, ceramic molding machines, manufacturing tools, etc., can solve the problems of poor concrete fluidity, concrete air bubbles, and affecting the pouring quality of laminated slabs, so as to reduce equipment costs and eliminate air bubbles , Improve the effect of the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

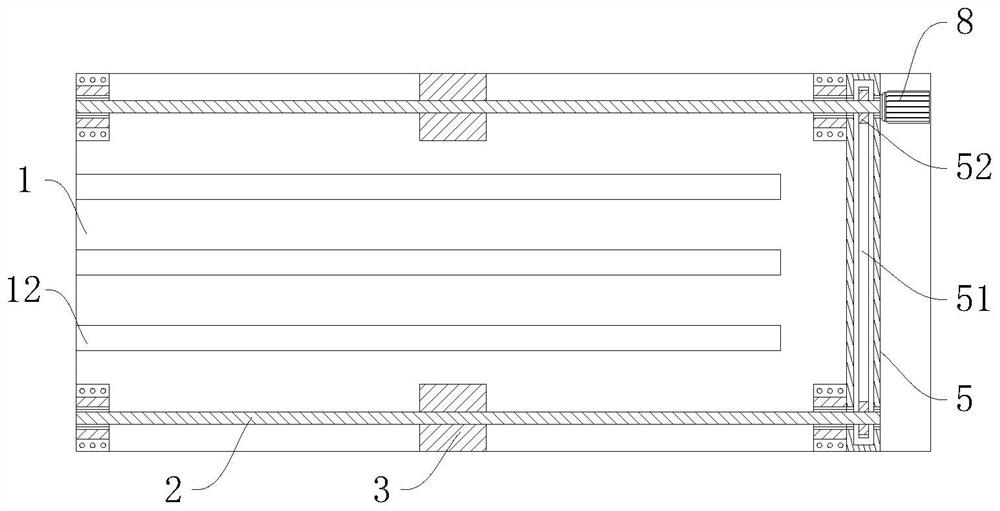

Method used

Image

Examples

Embodiment approach

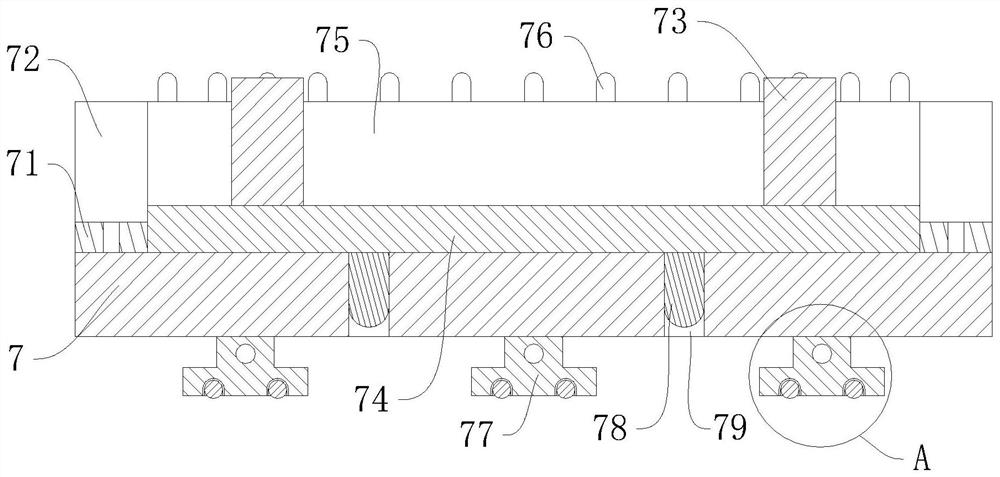

[0032] The specific embodiment, at first connect the circuit of vibrating machine 6, the first driver 8 and the second driver 91, and select the bottom formwork 74 of suitable specification, then the bottom formwork 74 is placed on the workbench plate 7 upper end, and utilize the first Two positioning columns 78 and the first positioning through hole 79 are used to position and install the bottom template 74 and the worktable 7, and then the transverse horizontal plate 75 is snapped into the corresponding adjustment slots 72 on the two support plates 71, and then Two horizontal horizontal plates 75 are installed on the workbench 7 by adjusting the draw-in groove 72. At this time, the two horizontal horizontal plates 75 are at the left and right ends of the bottom template 74, and then the vertical parts of the two T-shaped longitudinal templates 73 Both are inserted between the two transverse horizontal plates 75, and then the T-shaped longitudinal template 73 is attached to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com