Thin-wall cylindrical part clamp

A thin-walled cylinder and fixture technology, applied in the field of machining, can solve the problems of reduced precision and workpiece clamping deformation, and achieve the effects of reducing friction, reliable performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

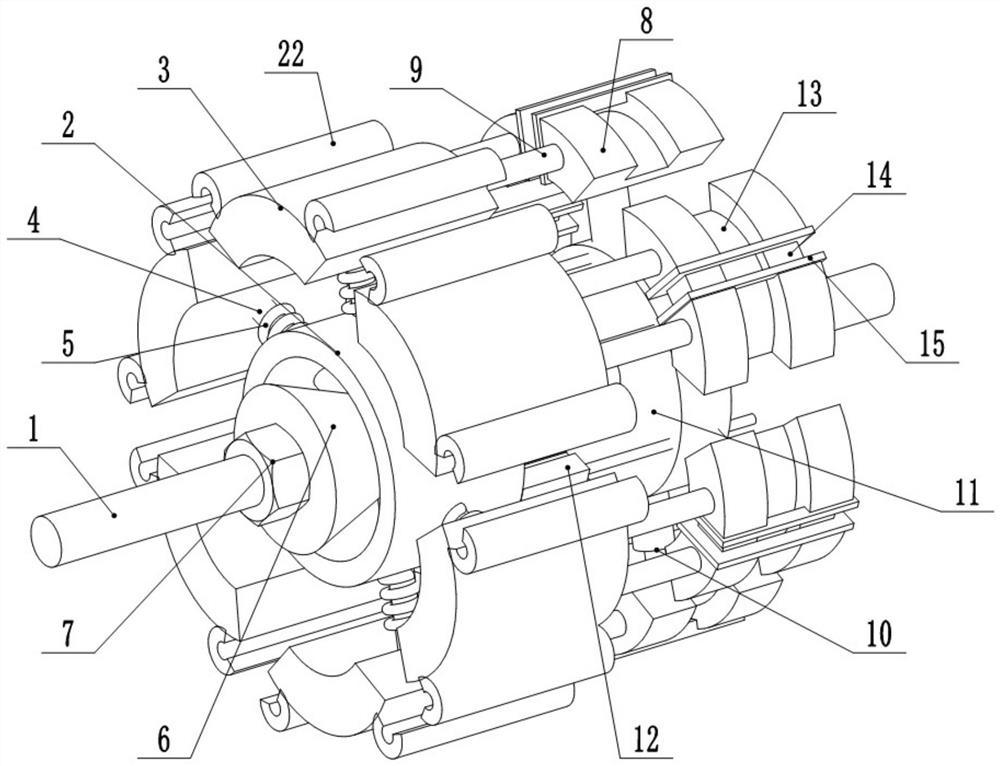

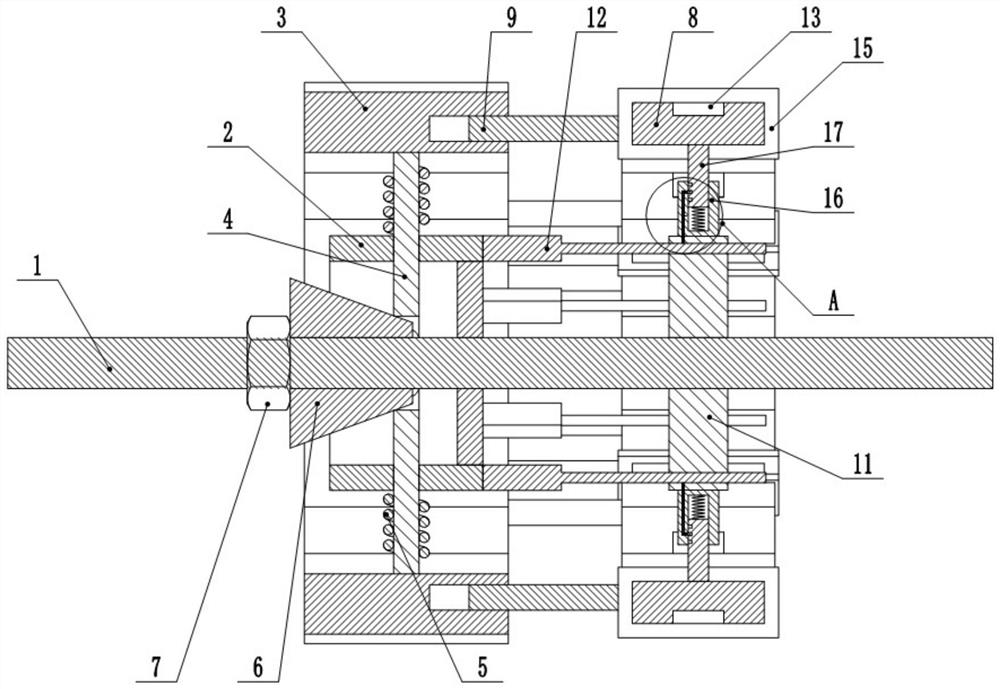

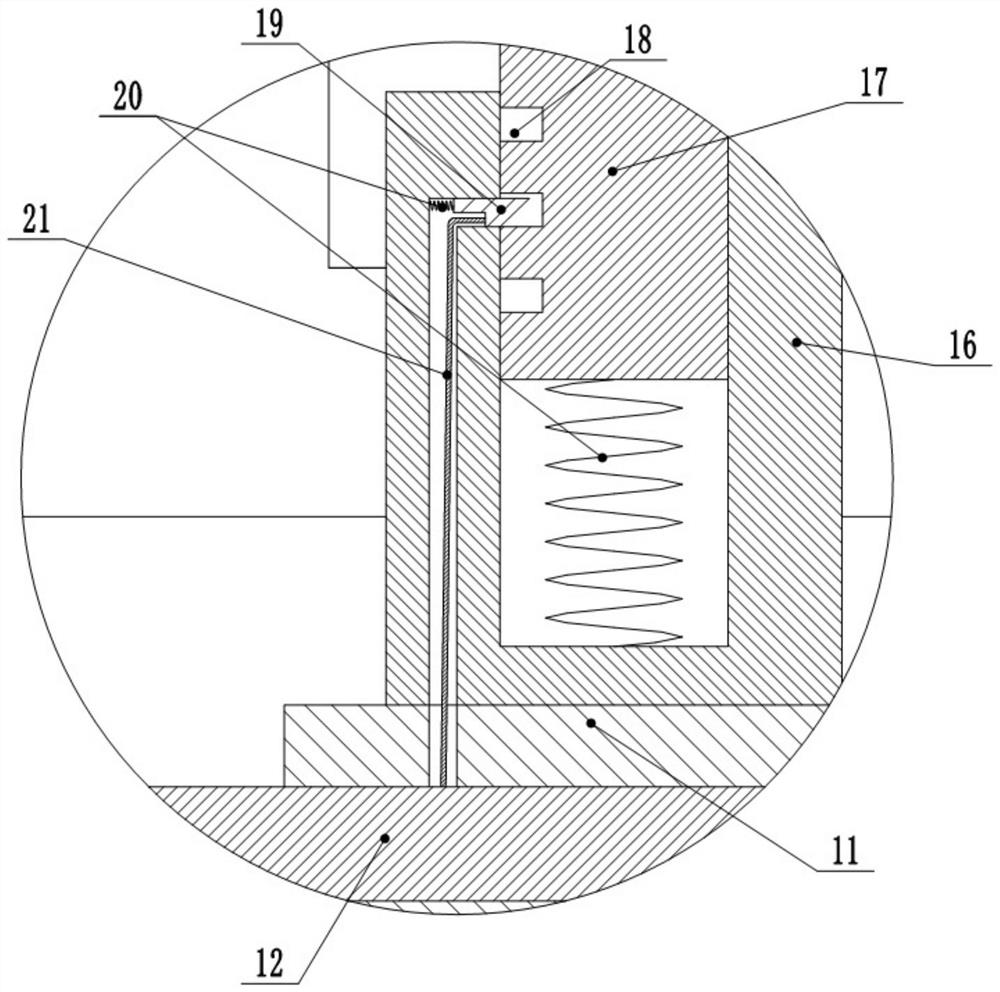

[0023] Such as figure 1 , figure 2 and image 3 Shown:

[0024] A fixture for thin-walled cylindrical parts, comprising a support shaft 1, a coaxial ring seat 2 is arranged on the support shaft 1, a coaxial connection ring is fixed on the inner side of the ring seat 2, and the connection ring is fixedly connected with the support shaft 1; There are several main support blocks 3 distributed in a circular array on the side of the seat 2, and the main support blocks 3 are all arc-shaped sections. It passes through and is slidably connected to the ring seat 2, and a return spring 5 is arranged between the connecting rod 4 and the ring seat 2; a nut 7 is threaded on the support shaft 1, and a frustum-shaped push block 6 is fixed on the end of the nut 7 , The propulsion block 6 is sleeved on the support shaft 1 .

[0025] Set the cylindrical piece on the support shaft 1, push the pusher block 6 into the annular seat 2 by rotating the nut 7, use the pusher block 6 to push the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com