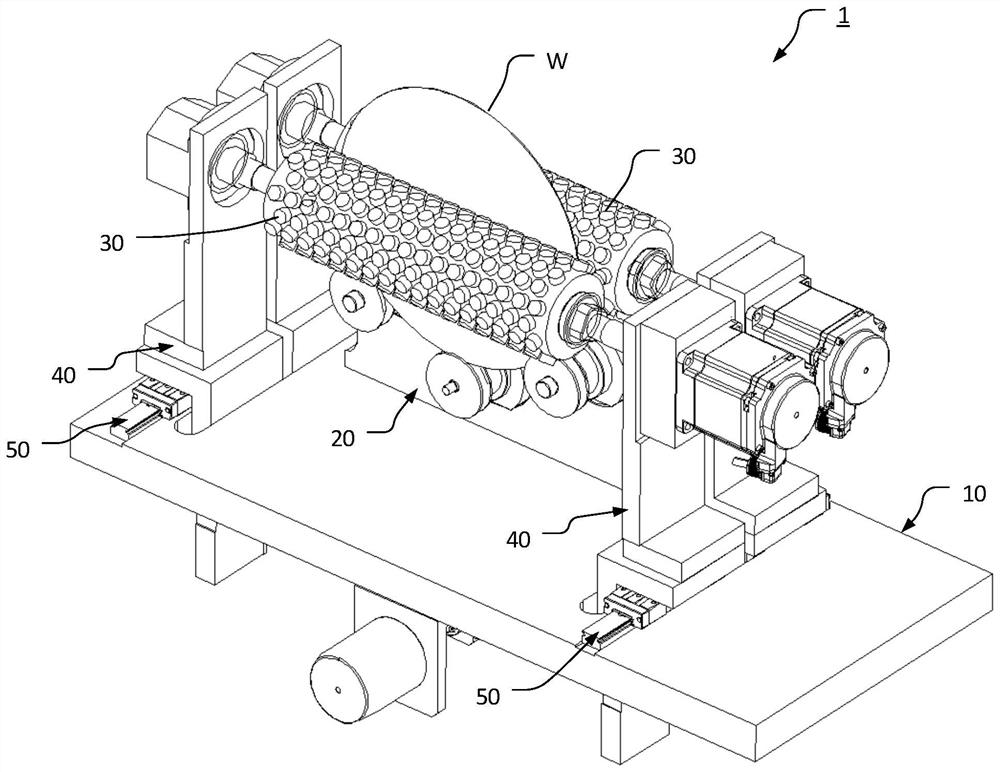

Wafer cleaning device capable of dynamically adjusting postures

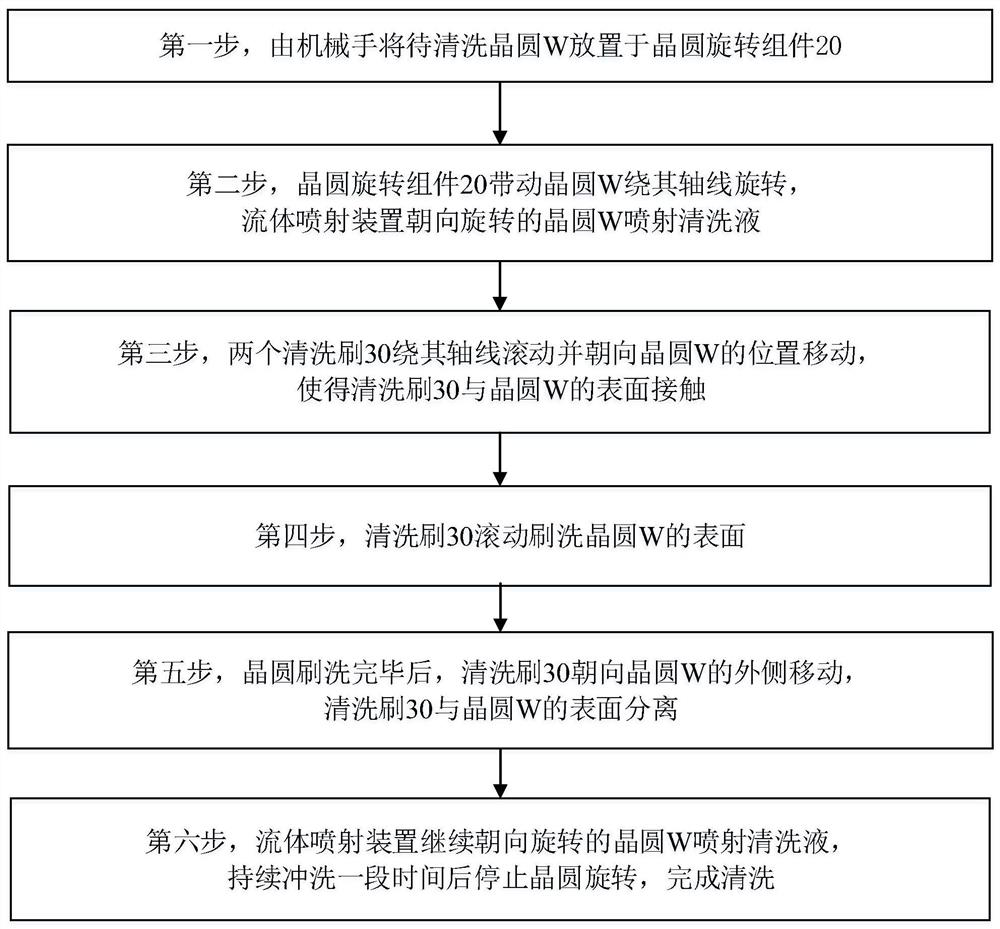

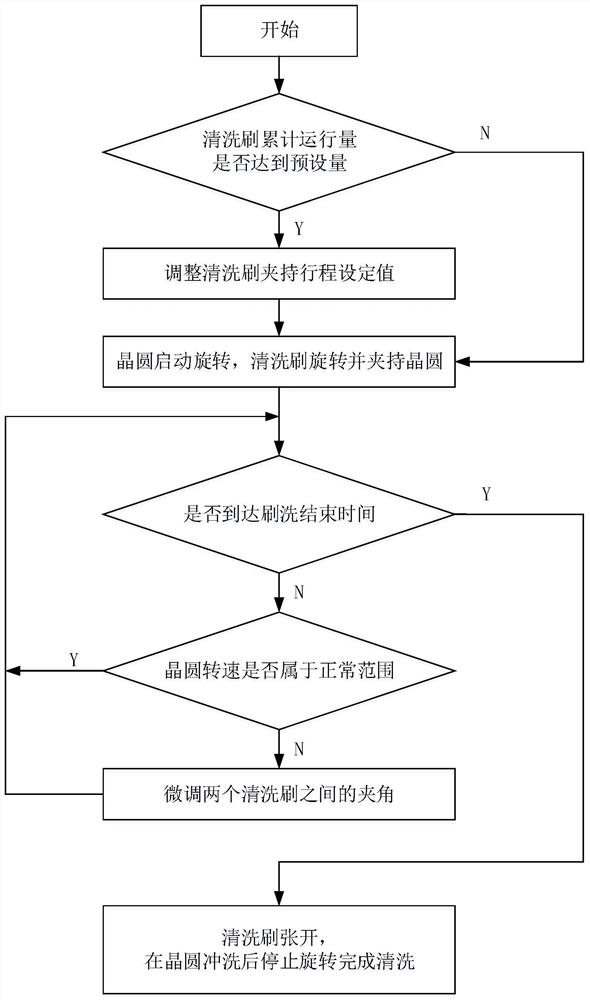

A cleaning device and dynamic adjustment technology, applied in the cleaning method using tools, cleaning method using liquid, cleaning method and utensils, etc., can solve the problem of affecting cleaning effect, unstable wafer brushing speed, inconsistent response time of cleaning solution, etc. problem, to achieve the effect of improving cleaning effect, improving consistency and stable speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]The technical solution of the present invention will be described in detail below in conjunction with specific embodiments and drawings. The embodiments described herein are the specific embodiments of the present invention, and the concepts of the present invention are intended to illustrate the present invention; those explanatory and exemplary are not to be construed as limiting the scope of the invention . In addition to the implementation exceptions described herein, those skilled in the art can also use obvious other technical solutions based on the claims disclosed in the present application and the description thereof, including any of the embodiments of the embodiments described herein. Obviously replacement and modification technology solutions. It should be understood that, unless otherwise stated, in order to facilitate understanding, the description of the specific embodiments of the present invention is established in the related equipment, means, components, or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com