HP-X3 full-automatic lens chip mounter

A HP-X3, fully automatic technology, used in mechanical equipment, devices for coating liquid on surfaces, material gluing, etc., can solve problems such as inability to automatically change disks, low degree of automation, and position offset.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

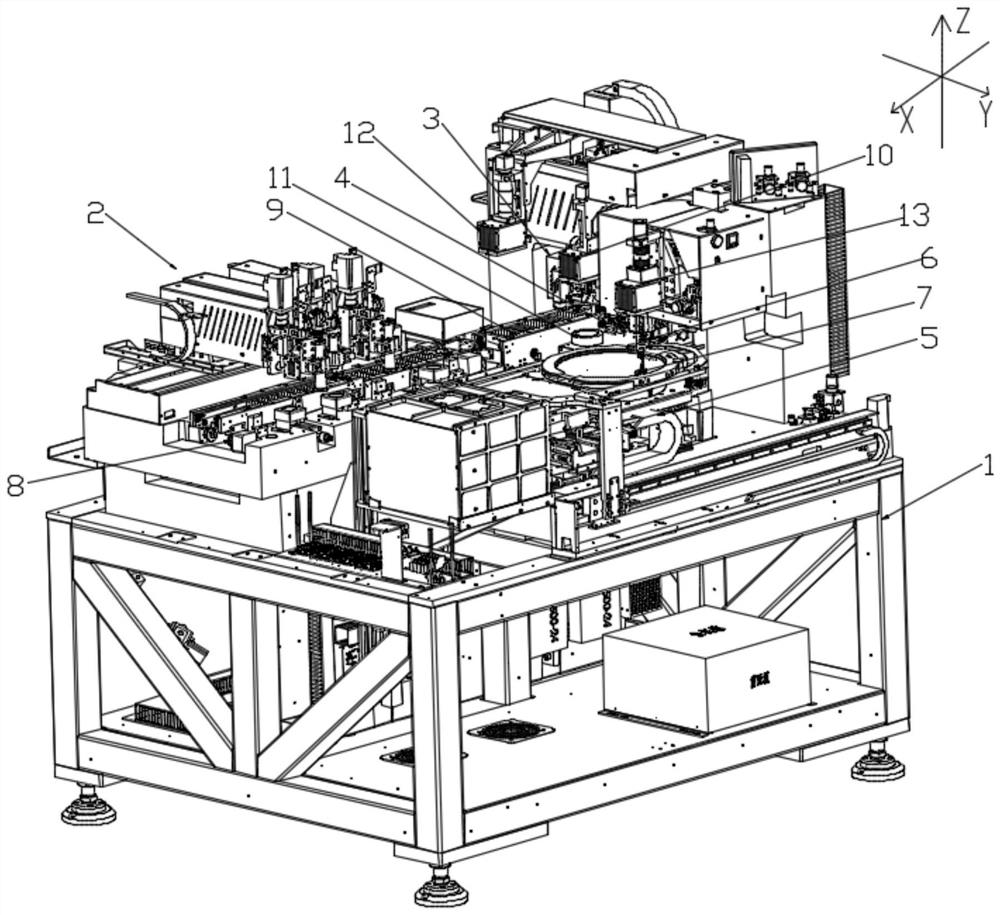

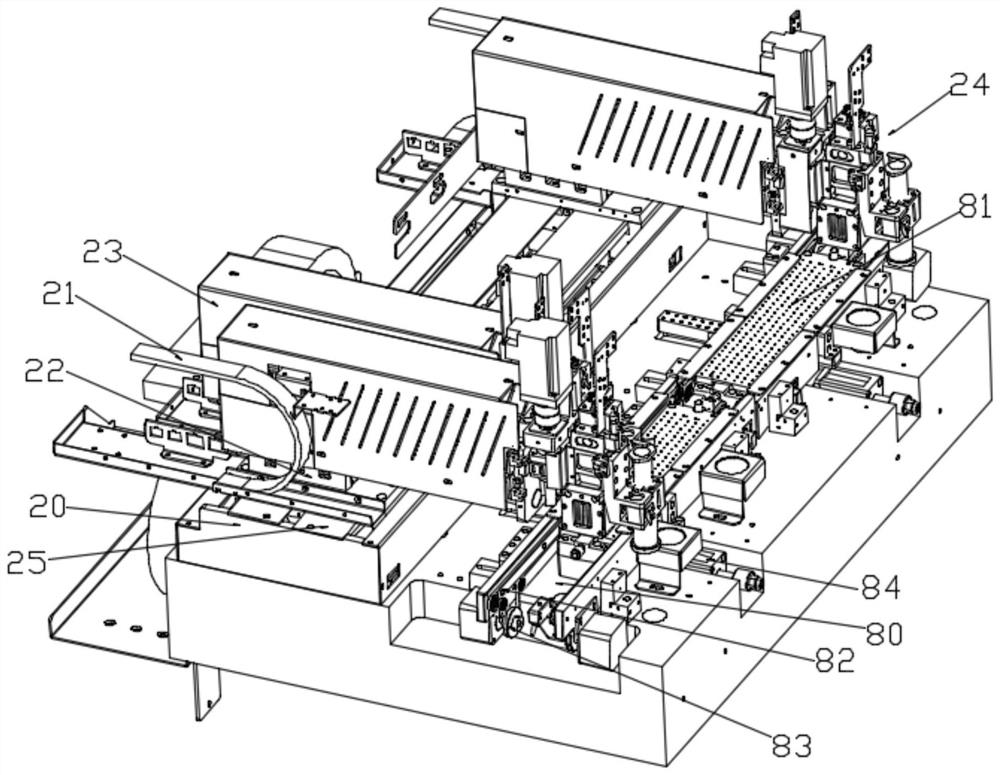

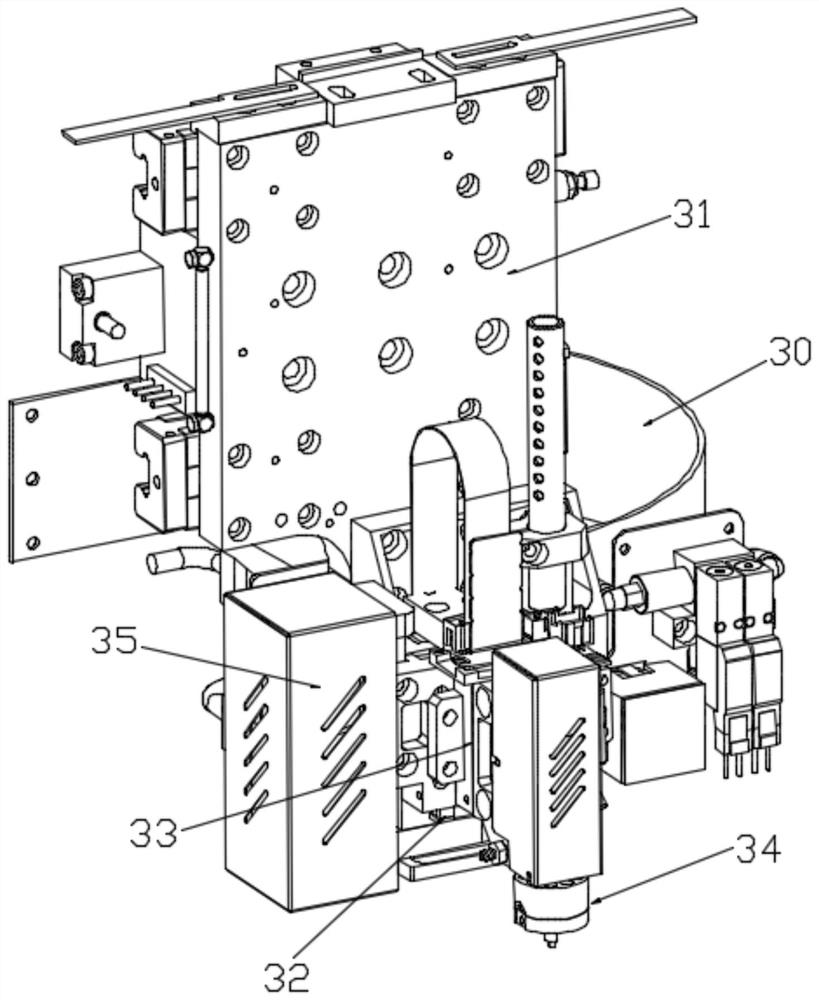

[0033] Please refer to Figure 1-Figure 11 , the present invention provides a HP-X3 fully automatic lens chip mounter, comprising: a frame 1, a dispensing mechanism 2 arranged on the frame 1, a patch mechanism 3, an offset correction component 4, an automatic disk changer Mechanism 5, the swing arm assembly 6 arranged on the upper side of the automatic disk changing mechanism 5; the dispensing drive assembly 8 is arranged on one side of the glue dispensing mechanism 2, and the thimble assembly is arranged at the bottom of the automatic disk changing mechanism 5 7. The upper and lower sides of the offset correction component 4 are respectively provided with a first position detection device 10 and a second position detection device 11; the dispensing mechanism 2 is used to align the jig points on the jig carrier Glue; the dispensing drive ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com