An automatic control platform for a pipeline anticorrosion and heat preservation glass fiber laying device

A glass fiber, laying device technology, applied in the direction of spray device, packaging, cleaning method and utensils, etc., can solve the problems of time-consuming and laborious, increase the cost of anti-corrosion, reduce the anti-corrosion efficiency of pipelines, etc., and achieve the effect of reducing cost and improving anti-corrosion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

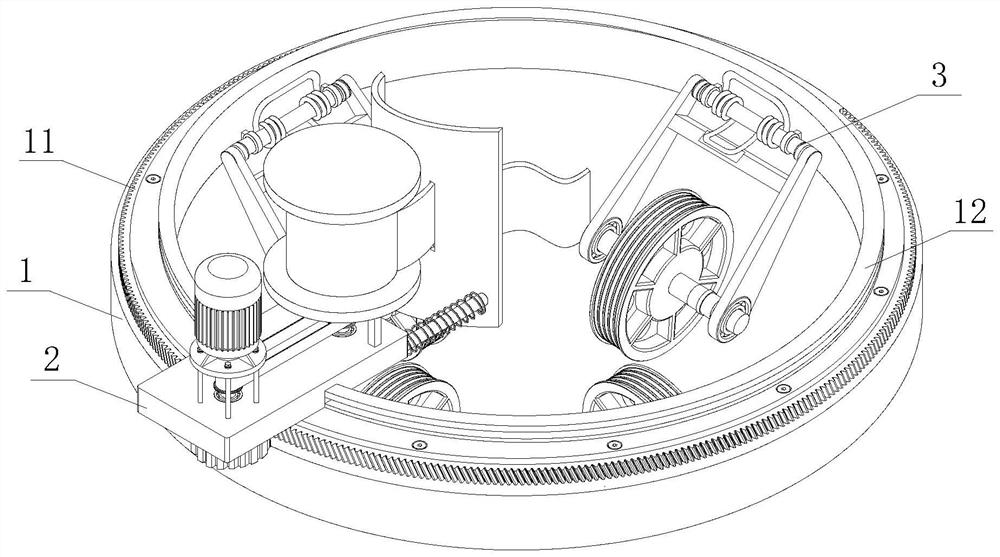

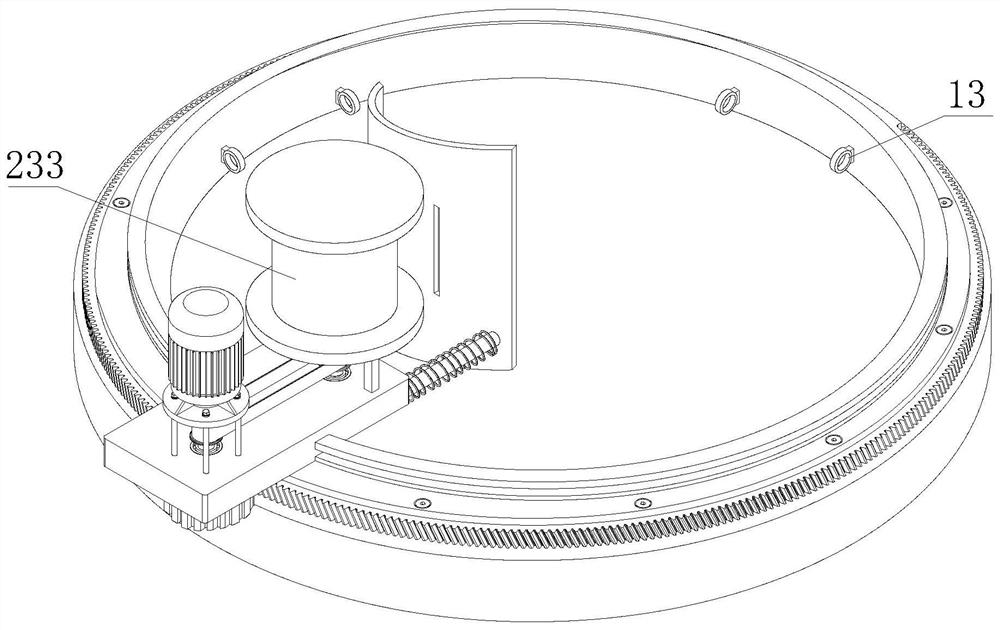

[0051] see Figure 1-Figure 2 , a pipeline anti-corrosion and thermal insulation glass fiber laying device, including an automatic installation cylinder 1, an automatic control platform, and a pipeline 5;

[0052] The upper surface of the automatic installation cylinder 1 is fixedly connected with an annular ring gear 11, the upper surface of the inner side of the annular gear 11 is fixedly connected with a limit slip ring 12, and the limit slip ring 12 is movably connected with a moving plate 2, and the inner wall of the automatic installation cylinder 1 The upper equidistant is connected with fixed suspension ring 13, and rotating wheel frame 3 is installed on the fixed suspension ring 13.

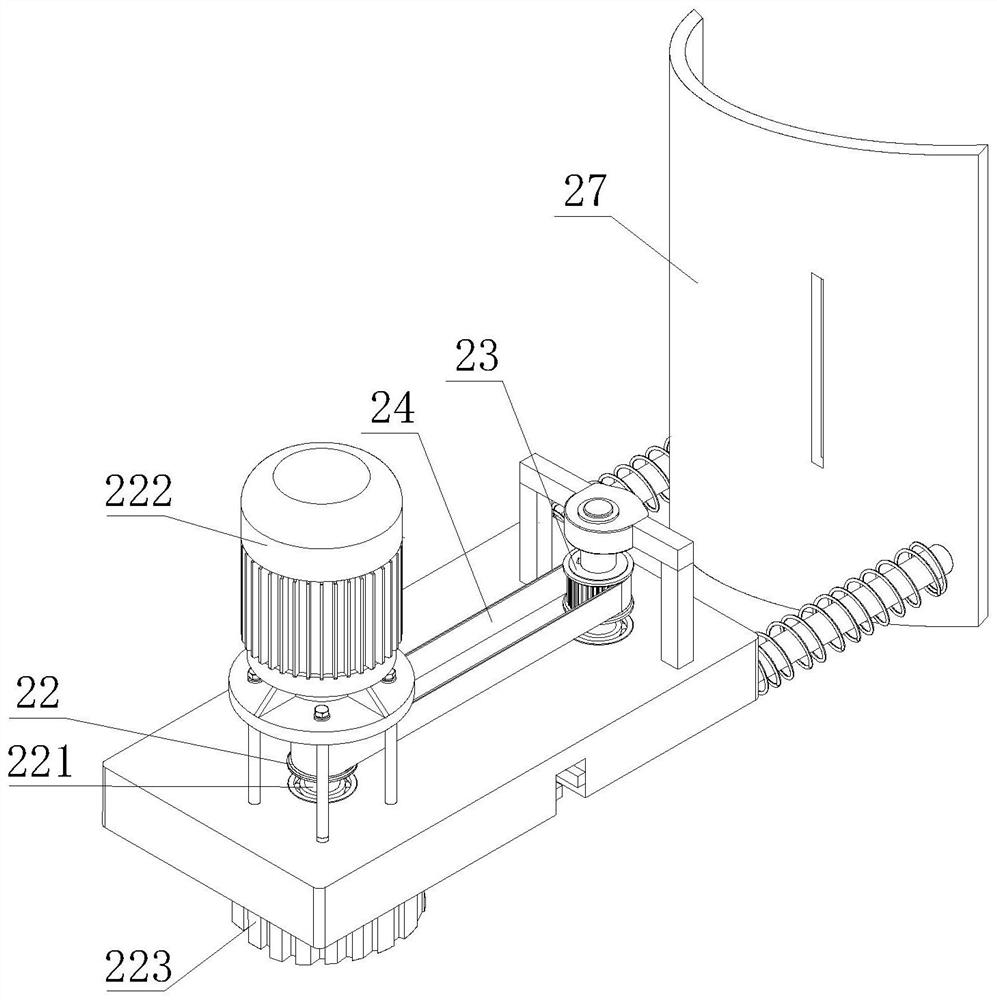

[0053] see Figure 3-Figure 5 , both ends of the moving plate 2 are provided with mounting holes 21, the first pulley 22 and the second pulley 23 are respectively connected by bearings in the mounting holes 21, and the transmission belt 24 is passed between the first pulley 22 and the s...

Embodiment 2

[0058] see Figure 9-Figure 10 , a pipeline anti-corrosion and thermal insulation glass fiber laying device, comprising an automatic installation cylinder 1, the upper surface of the automatic installation cylinder 1 is fixedly connected with an annular ring gear 11, and the upper surface of the inner side of the annular gear ring 11 is fixedly connected with a limit slip ring 12, and the limit The sliding ring 12 is movably connected with a moving plate 2, and the inner wall of the automatic installation cylinder 1 is equidistantly connected with a fixed suspension ring 13, and a rotating wheel frame 3 is installed on the fixed suspension ring 13. The automatic installation cylinder 1 includes the first half cylinder 14 and the second half cylinder. Two half tubes 15, the first half tube 14 and the second half tube 15 one ends are connected by a hinge, the other ends of the first half tube 14 and the second half tube 15 are connected with fixed ears 141, and the fixed ears 141...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com