A method for removing carbon from gasification slag

A gasification slag and slurry technology, applied in chemical instruments and methods, solid separation, electrostatic effect separation, etc., can solve the problems of increased cost, secondary pollution, etc., and achieve low cost, rapid carbon removal, and good carbon removal effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

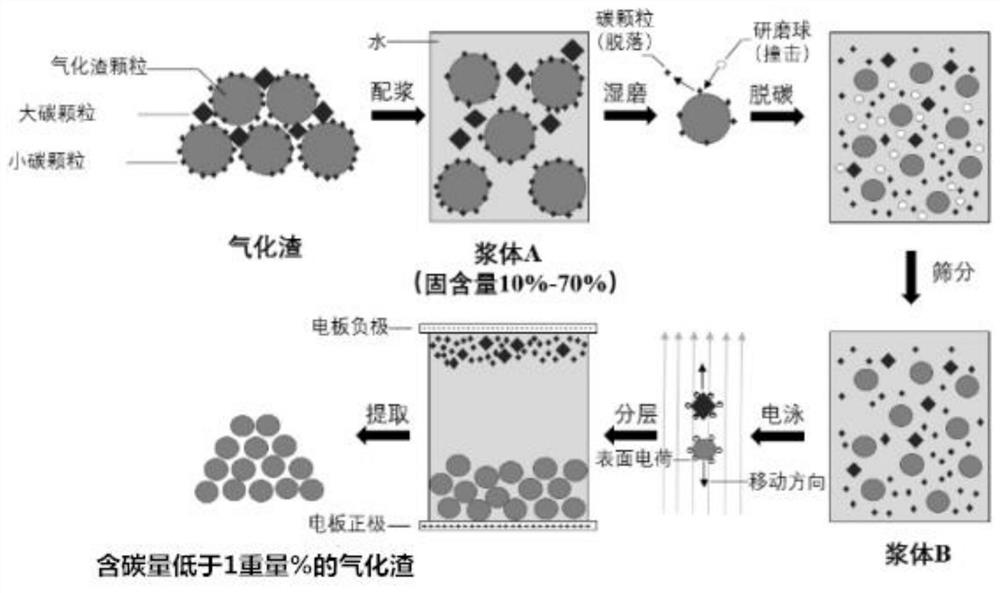

Method used

Image

Examples

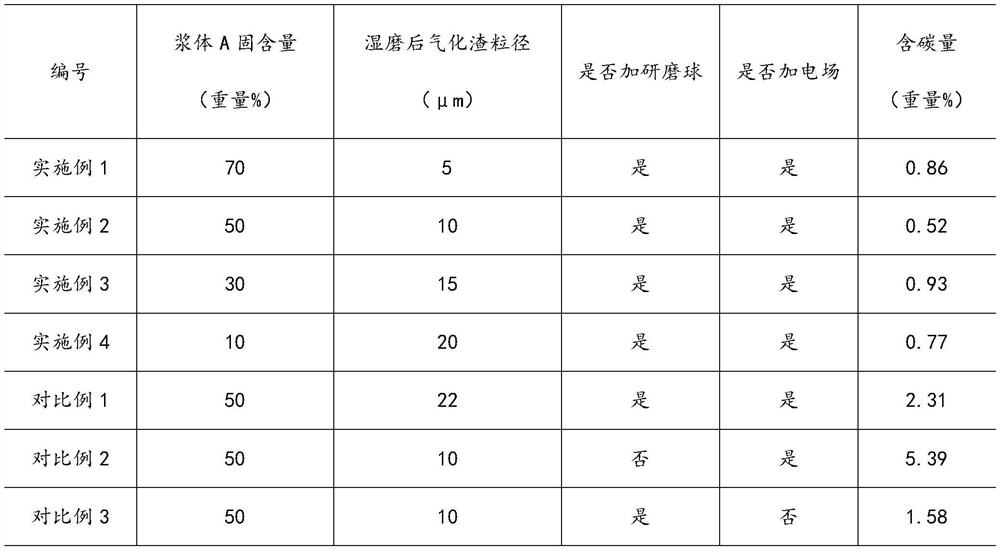

Embodiment 1

[0044] Example 1 is used to illustrate the method for removing carbon from gasification slag according to the present invention.

[0045] The method for removing carbon by wet grinding and gasification slag in this embodiment comprises the following steps in sequence:

[0046] (1) Take 70 parts of gasification slag and add 30 parts of water, mix and stir to prepare slurry A with a solid content of 70%;

[0047] (2) Take 100 parts by mass of slurry A, add grinding media, place it in a stirring wet mill and wet grind until the particle size is 5 μm, sieve and take out the grinding medium to obtain slurry B;

[0048] In step (2), the following wet grinding process parameters are adopted:

[0049] The grinding medium is zirconia grinding balls with a particle size of 0.5-3.0mm. The filling rate of the grinding medium is 70%, the weight ratio of the ball to material is 1:4, and the stirring shaft speed of the wet mill is 400r / min. The grinding time is 60min.

[0050] (3) Put the...

Embodiment 2

[0055] Example 2 is used to illustrate the method for removing carbon from gasification slag according to the present invention.

[0056] The method for removing carbon by wet grinding and gasification slag in this embodiment comprises the following steps in sequence:

[0057] (1) Take 50 parts of gasification slag and add 50 parts of water, mix and stir to prepare slurry A with a solid content of 50%;

[0058] (2) Take 100 parts by mass of slurry A, add grinding media, place it in a stirring wet mill and wet grind it to a particle size of 10 μm, sieve and take out the grinding medium to obtain slurry B;

[0059] In step (2), the following wet grinding process parameters are adopted:

[0060] The grinding medium is zirconia grinding balls with a particle size of 0.5-3.0mm. The filling rate of the grinding medium is 70%, the weight ratio of the ball to material is 1:4, and the stirring shaft speed of the wet mill is 400r / min. The grinding time is 40min.

[0061] (3) Put the ...

Embodiment 3

[0066] Example 3 is used to illustrate the method for removing carbon from gasification slag according to the present invention.

[0067] The method for removing carbon by wet grinding and gasification slag in this embodiment comprises the following steps in sequence:

[0068] (1) Take 30 parts of gasification slag and add 70 parts of water, mix and stir to prepare slurry A with a solid content of 30%;

[0069] (2) Take 100 parts by mass of slurry A, add grinding media, place it in a stirring wet mill for wet grinding to a particle size of 15 μm, sieve and take out the grinding media to obtain slurry B;

[0070] In step (2), the following wet grinding process parameters are adopted:

[0071] The grinding medium is zirconia grinding balls with a particle size of 0.5-3.0mm. The filling rate of the grinding medium is 65%, the weight ratio of the ball to material is 1:3, and the stirring shaft speed of the wet mill is 350r / min. The grinding time is 30min.

[0072] (3) Put the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com