Centrifuge tube suction filtration device

A suction filtration device and centrifuge tube technology, applied in the field of suction filtration, can solve the problems of loss, cross-contamination of samples, and complicated operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

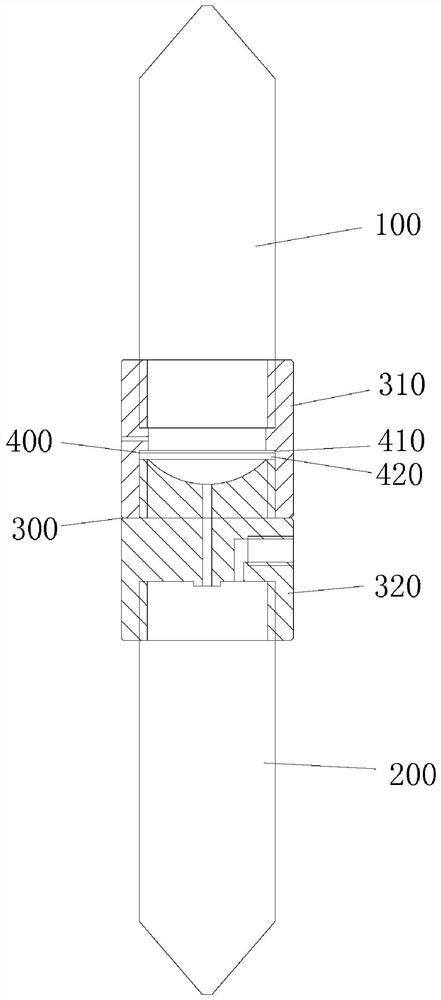

[0042] This embodiment provides a centrifuge tube suction filtration device, such as Figure 1-6 As shown, it includes a first centrifuge tube 100, a second centrifuge tube 200, a connection assembly 300 and a filter assembly 400, wherein the first centrifuge tube 100 and the second centrifuge tube 200 are connected through the connection assembly 300, and the filter assembly 400 is assembled on the connection within the assembly 300.

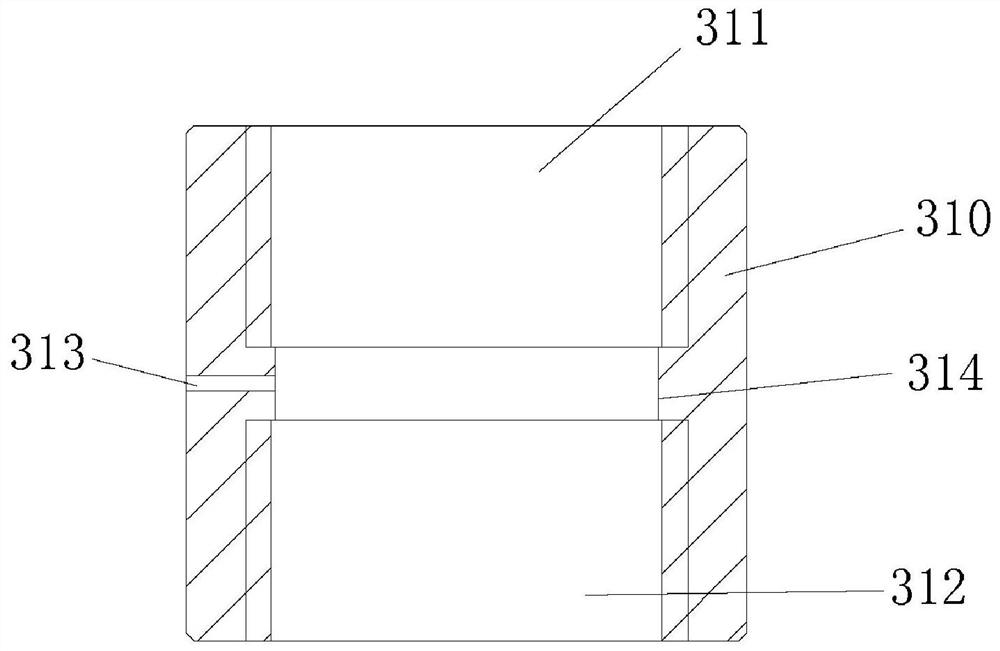

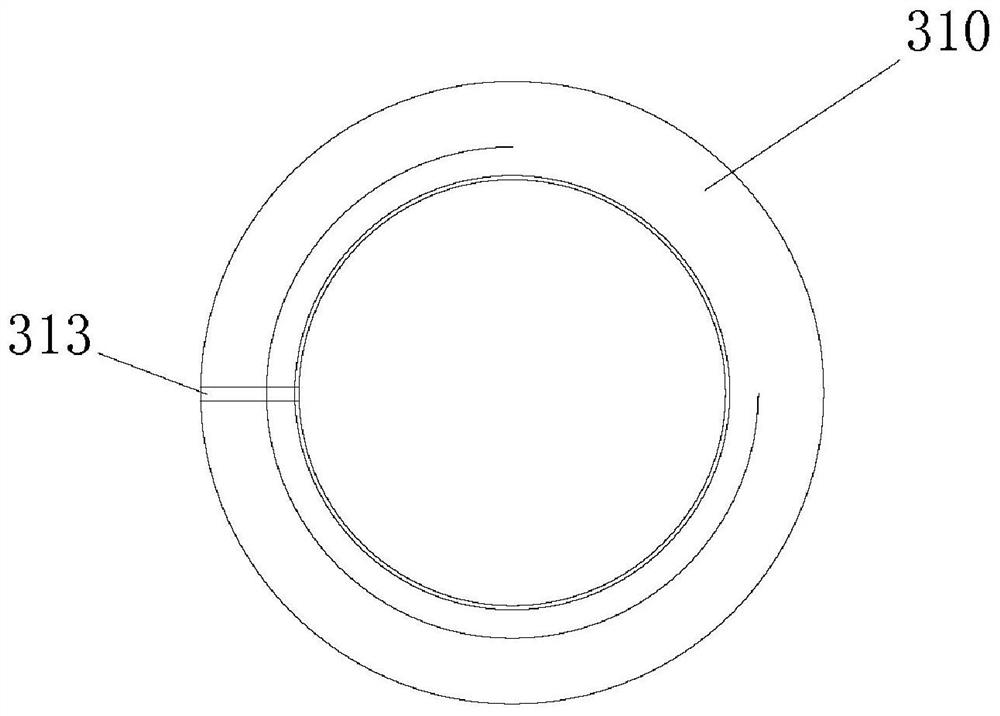

[0043] Wherein the connecting assembly 300 includes a first connecting seat 310 and a second connecting seat 320 connected to each other, the first connecting seat 310 is detachably connected with the first centrifuge tube 100 as a whole, the second connecting seat 320 and the second centrifuge tube 200 can be detachably connected together;

[0044] The first connection seat 310 is provided with a first connection groove 311 and a second connection groove 312, the second connection seat 320 is provided with a third connection groove 321 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com