Real-time cutting device for sugarcane planting

A cutting equipment and sugarcane technology, applied in the field of real-time cutting equipment for sugarcane planting, can solve problems such as inability to cut sugarcane, affect sugarcane infestation, and inability to sterilize the cutting surface, so as to improve germination rate, avoid insect disease, and facilitate management Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

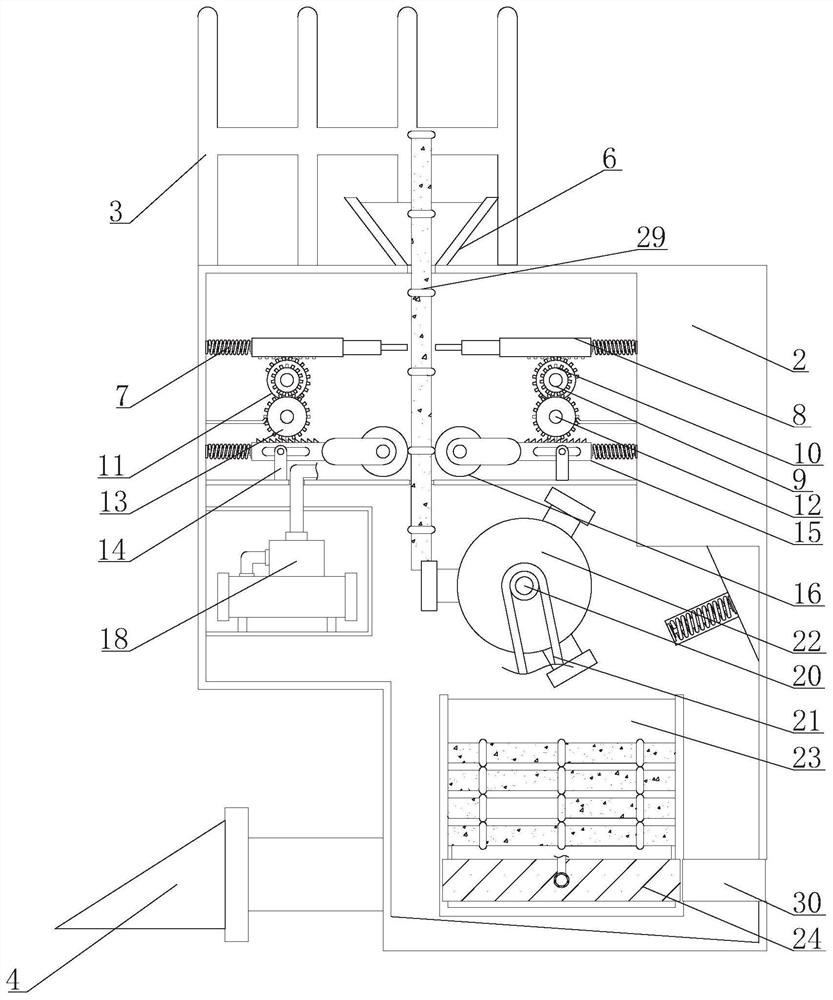

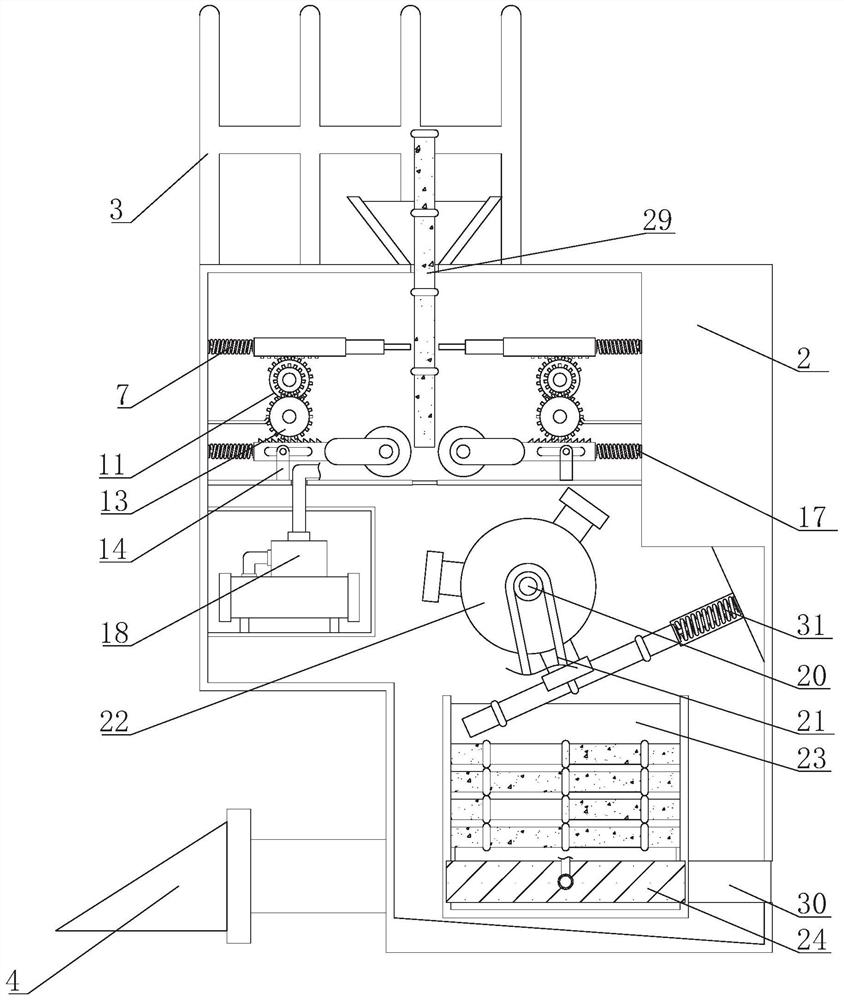

[0030] Embodiment 1, through the inner two sides of the installation bin 2 are jointly provided with the shift lever that is compatible with the second transmission gear 13, the movable lever 15 moves in the opposite direction to drive the second transmission gear 13 to rotate relatively, and when the sugarcane body 29 moves down, there is no Node, the stretching of the second spring 17 drives the movable rod 15 to move relatively, and the adjustment wheel 16 continues to be clamped on the surface of the sugarcane body 29. At this time, the shift lever drives the second transmission gear 13 to fix, so that the second transmission gear 13 will not follow the With the relative movement of the movable rod 15, the opposite rotation is carried out, and then the continuous contraction of the first spring 7 guaranteed.

Embodiment 2

[0031] Embodiment 2, the incomplete gear 11 installed through the surface rotation of the first installation rod 9, and the gear number distribution of the incomplete gear 11 occupies three quarters of the overall incomplete gear 11, so that when the adjustment wheel 16 encounters the first During the first node, the second transmission gear 13 drives the incomplete gear 11 to rotate a quarter by driving the first transmission gear 10, and the incomplete gear 11 drives the cutting knife 8 to move a quarter in reverse, and then when the adjustment wheel 16 meets the first Incomplete gear 11 breaks away from cutter 8 during three nodes, so that a spring 7 is stretched to drive cutter 8 to move relative to the cutting work, and then the sugarcane body 29 node numbers that have been cut are guaranteed to be fixed.

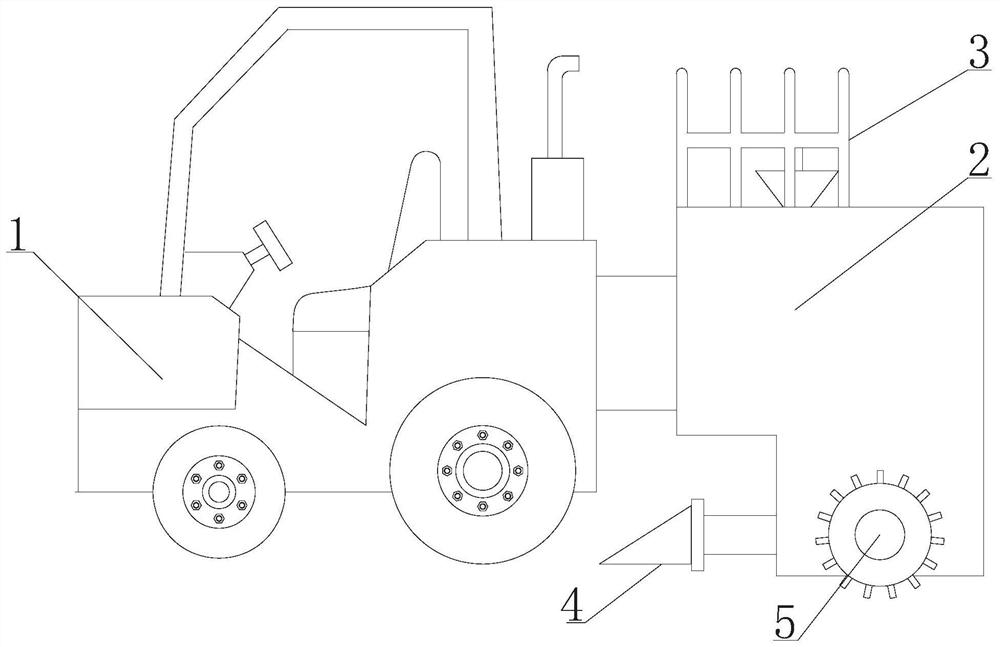

[0032] Working principle: When planting sugarcane needs to be cut, the driving vehicle 1 drives the installation warehouse 2 to move in the field, and the plow 4 works....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com