Segmented splicing method and device, electronic equipment and storage medium

A technology of segmentation splicing and position information, applied in image analysis, image data processing, instruments, etc., can solve the problems of incomplete exposure of materials, overlapping of exposure graphics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

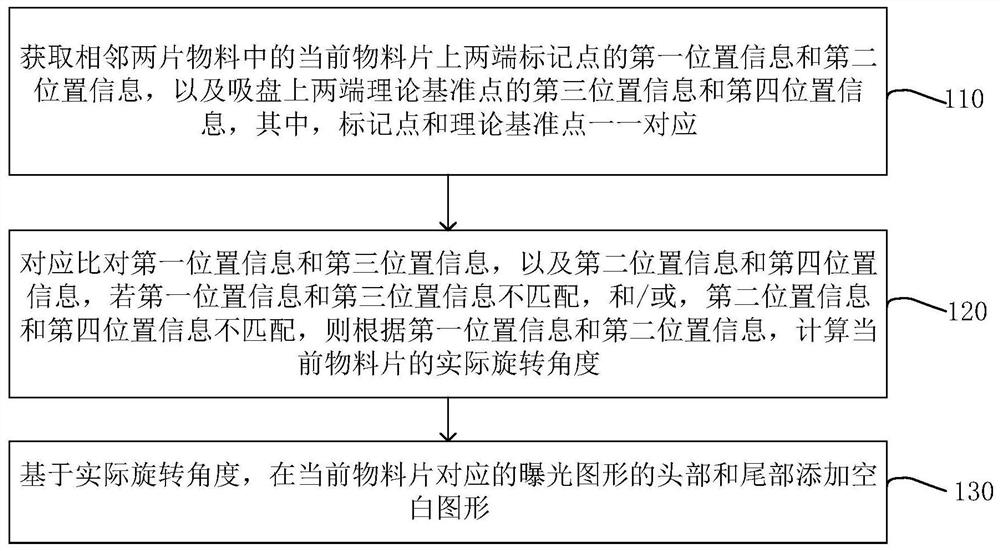

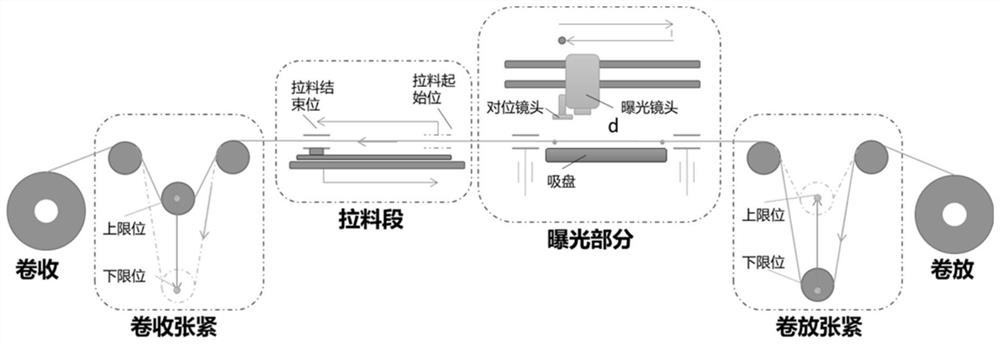

[0031] figure 1 It is a flow chart of the segmented splicing method provided by Embodiment 1 of the present invention. This embodiment is applicable to the process of pulling materials. Due to the deviation of the pulling angle, the material exposure is incomplete, or two adjacent pieces of material are exposed. In the case of the problem of overlapping graphics, the method can be performed by a segmented stitching device, which can be implemented by software and / or hardware, and the segmented stitching device can be configured on an electronic computing device, specifically including the following steps :

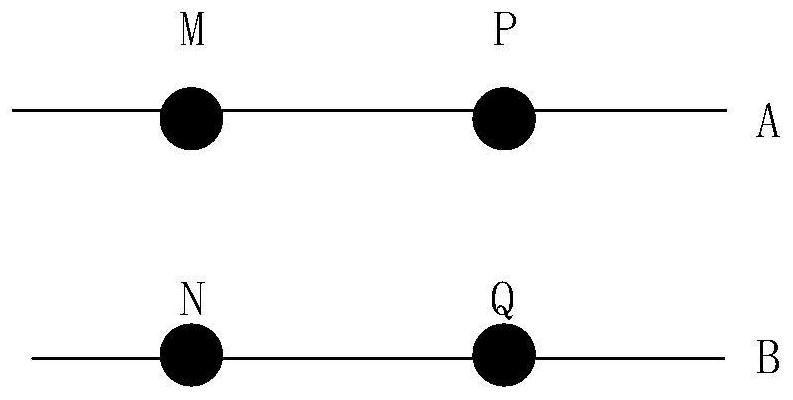

[0032] S110. Obtain the first position information and the second position information of the marking points at both ends of the current material sheet in the two adjacent pieces of material, and the third position information and the fourth position information of the theoretical reference points at both ends of the suction cup, wherein the marking There is a one-to-one ...

Embodiment 2

[0078] Image 6 It is a flow chart of the segment splicing method provided by Embodiment 2 of the present invention. The embodiment of the present invention can be combined with various alternative solutions in the foregoing embodiments. In the embodiment of the present invention, optionally, before adding a blank graphic to the head and tail of the exposure graphic corresponding to the current material sheet, the method further includes: determining the graphic corresponding to the actual rotation angle according to the actual rotation angle area.

[0079] Such as Image 6 As shown, the method of the embodiment of the present invention specifically includes the following steps:

[0080] S210. Obtain the first position information and the second position information of the marking points at both ends of the current material sheet in the two adjacent pieces of material, and the third position information and the fourth position information of the theoretical reference points ...

Embodiment 3

[0120] Figure 9 A schematic structural diagram of the segmented splicing device provided in Embodiment 3 of the present invention, as shown in Figure 9 As shown, the device includes: an information acquisition module 31 , an actual rotation angle determination module 32 and a stitching compensation module 33 .

[0121] Among them, the information acquisition module 31 is used to obtain the first position information and the second position information of the marking points at both ends of the current material sheet in the two adjacent pieces of material, and the third position information and the second position information of the theoretical reference points at both ends of the sucker. Four position information, wherein, the marking points correspond to the theoretical reference points one by one;

[0122] The actual rotation angle determination module 32 is configured to compare the first position information with the third position information, and the second position in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com