Needle head of guide needle

A technology of guiding needles and needles, applied in the directions of guiding needles, catheters, etc., can solve the problems of difficulty in maintaining the sharpness of the needle tip, unfavorable wound suturing and healing, and large puncture resistance, so as to eliminate transverse cutting injuries, facilitate suturing and healing, The effect of reducing puncture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

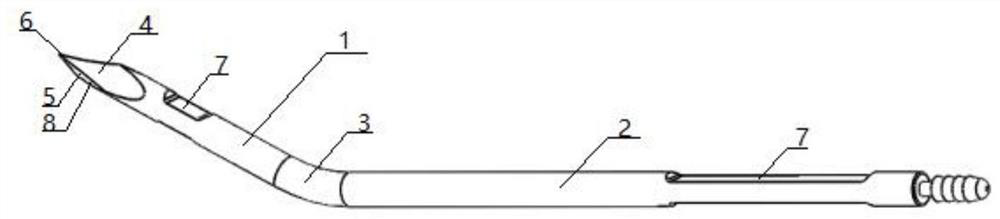

Embodiment 1

[0033] The present invention provides a guide needle needle head, comprising an inner cutting edge plane 4, one side of the inner cutting edge plane 4 is provided with an outer cutting edge plane 5, and the inner cutting edge plane 4 and the outer cutting edge plane 5 intersect at the needle tip 6 , the inner cutting edge plane 4 is asymmetrical to the outer cutting edge plane 5, that is, it is asymmetrical about the central axis of the needle 1, and the size of the outer cutting edge plane 5 is smaller than the size of the inner cutting edge plane 4, and the size is the cutting edge plane width and length; if the inner cutting edge plane 4 is completely symmetrical to the outer cutting edge plane 5, the cutting edge plane will be perpendicular to the plane where the puncture line is located, which will cause serious transverse damage to the tissue (especially muscle) during puncture Cutting, through the asymmetric setting, the plane of the cutting edge can be coplanar with the...

Embodiment 2

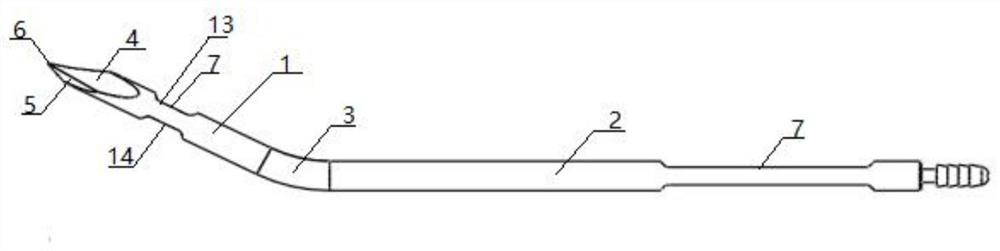

[0035] In this embodiment, the inner cutting edge plane 4 and the outer cutting edge plane 5 are specifically defined. Specifically, the inner cutting edge plane 4 includes a first inner cutting edge plane 9 and a second inner cutting edge plane 10. One side of an inner cutting edge plane 9 is provided with a second inner cutting edge plane 10, and the other side of the first inner cutting edge plane 9 is provided with a first outer cutting edge plane 11, and the first outer cutting edge plane One side of 11 is provided with a second outer cutting edge plane 12, one side of the second outer cutting edge plane 12 is provided with a second inner cutting edge plane 10, and one side of the second inner cutting edge plane 10 is provided with The first inner cutting edge plane 9; the intersection line between the first inner cutting edge plane 9 and the second inner cutting edge plane 10, the intersection between the first inner cutting edge plane 9 and the first outer cutting edge p...

Embodiment 3

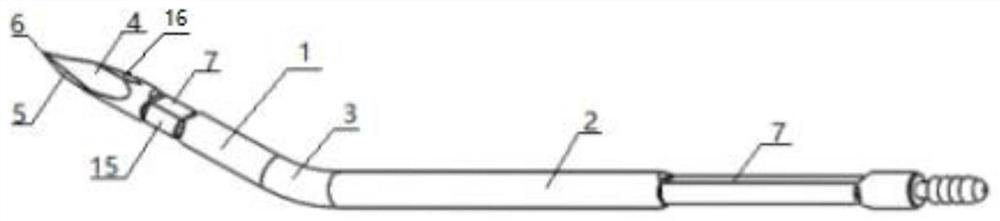

[0040] In this embodiment, a facet 16 is provided at the intersection line 8 between the inner cutting edge 4 and the outer cutting edge 5; more specifically, between the first inner cutting edge 9 and the first outer cutting edge 11 1. A facet 16 is provided at the intersection line 8 between the second inner cutting edge 10 and the second outer cutting edge 12; the length of the cutting edge is further reduced, and the width of the tissue longitudinally cut during operation is further reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com