Oil jacket safety packer with anchoring function and method thereof

A packer and anchoring technology is applied in the field of tubing and casing annular safety protection devices, which can solve problems such as hidden dangers of well control safety, easy failure of tools, unreasonable design of well cleaning structures, etc. Variable volume, reducing the possible effect of encountering a card

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

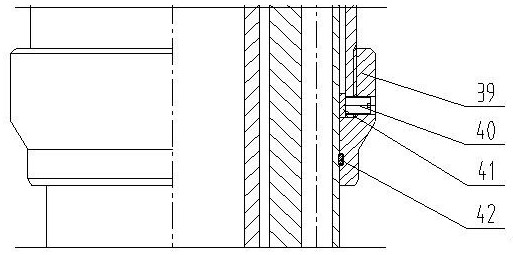

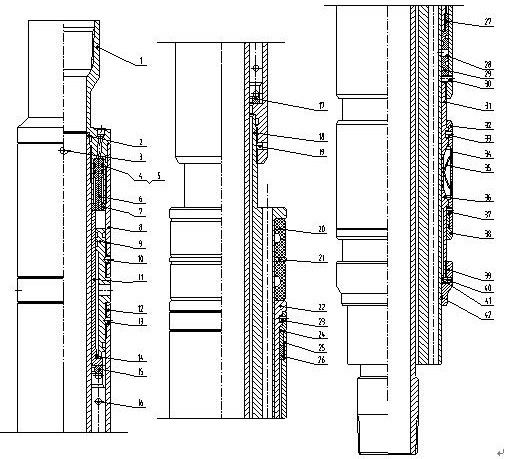

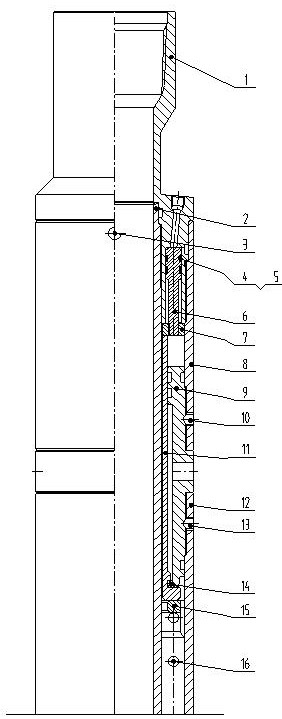

[0069] see Figure 1 to Figure 5 , the present invention provides a technical solution: an anchored oil jacket safety packer, comprising:

[0070] A large-displacement well-flushing control device, the large-displacement well-flush control device is set outside the center pipe 2, and the upper end of the large-displacement well-flush control device is connected to the first hydraulic control pipeline;

[0071] The packer setting, anchoring and unsealing device is set on the outside of the central pipe, and the upper end of the packer setting, anchoring and unsealing device is connected to the second hydraulic control pipeline.

[0072] Further, the large displacement well flushing control device includes:

[0073] The backwash sleeve 9, the upper end of the backwash sleeve is connected to the piston sleeve 8, the piston sleeve is installed with the piston 6, the lower end of the backwash sleeve is a spring sleeve 12, and the middle part of the backwash sleeve is provided with...

Embodiment 2

[0137] see figure 1 , the present invention provides a technical solution: an anchored oil jacket safety packer, comprising:

[0138] A large-displacement well-flushing control device, the large-displacement well-flush control device is set outside the center pipe 2, and the upper end of the large-displacement well-flush control device is connected to the first hydraulic control pipeline;

[0139] The packer setting, anchoring and unsealing device is set on the outside of the central pipe, and the upper end of the packer setting, anchoring and unsealing device is connected to the second hydraulic control pipeline.

[0140] Further, the large displacement well flushing control device includes:

[0141] The backwash sleeve 9, the upper end of the backwash sleeve is connected to the piston sleeve 8, the piston sleeve is equipped with a piston 6, the lower end of the backwash sleeve is a spring sleeve 12, and the middle part of the backwash sleeve is provided with a radially conn...

Embodiment 3

[0173] see figure 1 , the present invention provides a technical solution: an anchored oil jacket safety packer, comprising:

[0174] A large-displacement well-flushing control device, the large-displacement well-flush control device is set outside the center pipe 2, and the upper end of the large-displacement well-flush control device is connected to the first hydraulic control pipeline;

[0175] The packer setting, anchoring and unsealing device is set on the outside of the central pipe, and the upper end of the packer setting, anchoring and unsealing device is connected to the second hydraulic control pipeline.

[0176] Further, the large displacement well flushing control device includes:

[0177] The backwash sleeve 9, the upper end of the backwash sleeve is connected to the piston sleeve 8, the piston sleeve is installed with the piston 6, the lower end of the backwash sleeve is a spring sleeve 12, and the middle part of the backwash sleeve is provided with a radially c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com