Anti-tearing emergency stop device suitable for belt conveyor head

A belt conveyor and anti-tear technology, applied in conveyor control devices, conveyors, conveyor objects, etc., can solve the problems of conveyor belt breakage, economic loss, and reducing the braking effect of belt conveyors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

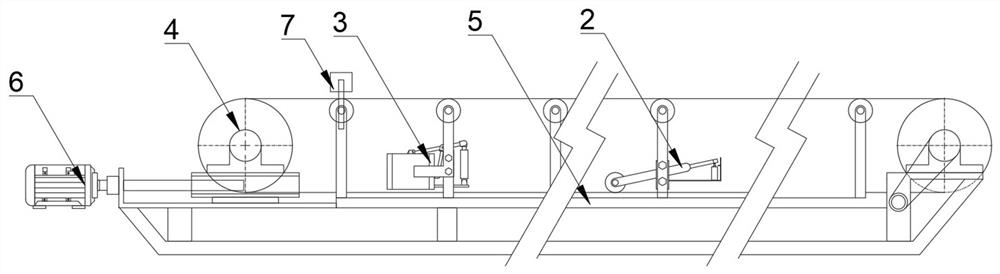

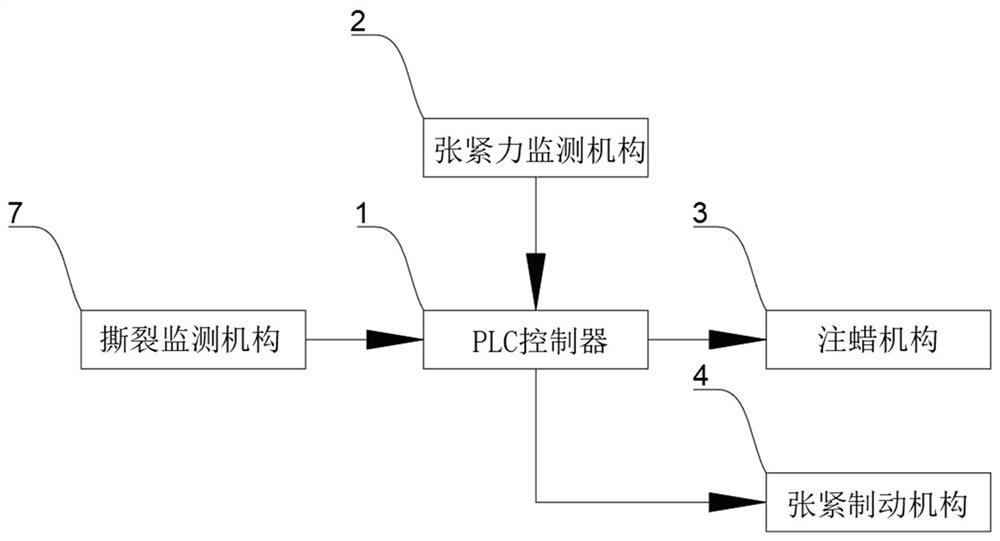

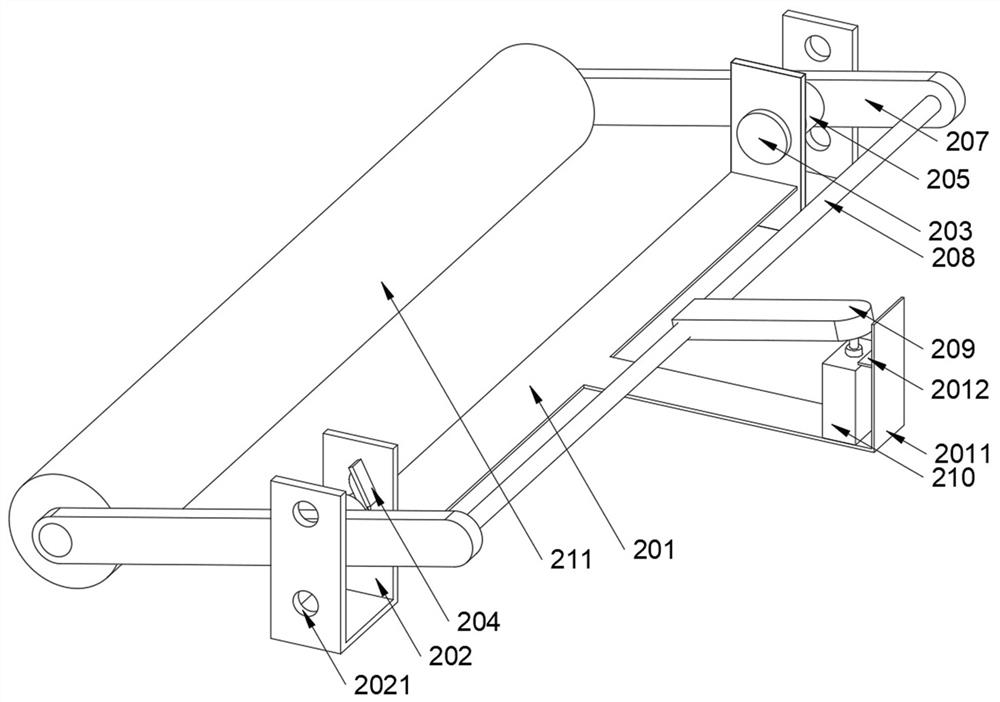

[0027] see Figure 1-Figure 7 , the present invention provides the following technical solutions: an anti-tear emergency stop device suitable for the head of a belt conveyor, including a PLC controller 1, a tension monitoring mechanism 2, a wax injection mechanism 3, a tension brake mechanism 4, a tear The crack monitoring mechanism 7, the tension monitoring mechanism 2 is fixedly installed on the middle side of the belt conveyor 5, the wax injection mechanism 3 is fixedly installed on the tail side of the belt conveyor 5, and the wire in the tension braking mechanism 4 One end of the rod is fixedly connected to the output shaft of the tensioning motor 6, and the tension monitoring mechanism 2 includes a T-shaped frame 201, and the two ends of the T-shaped frame 201 are fixedly connected to the sides of the U-shaped frame 202, and the U-shaped frame The side of 202 is rotatably equipped with a rotating shaft 203, one end of the rotating shaft 203 is fixedly connected to the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com