Anti-freezing device at bottom of coal gondola car carriage

A technology for anti-freezing and compartments, which is applied in the fields of anti-freezing devices at the bottom of the compartments for coal transport gondolas, bottom freezing devices, and anti-freezing devices. Achieve the effect of easy promotion, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

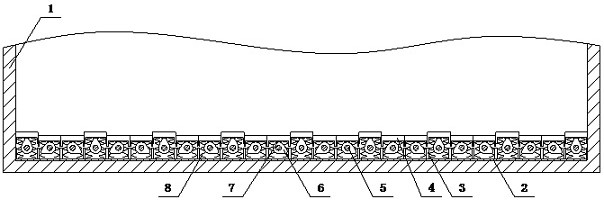

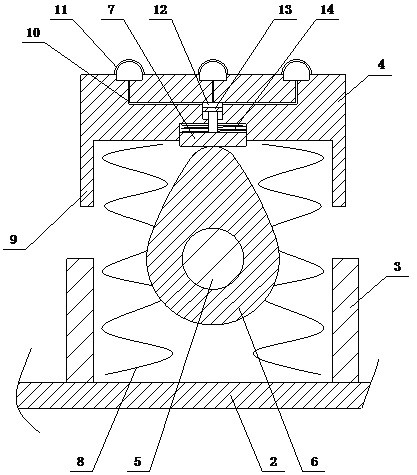

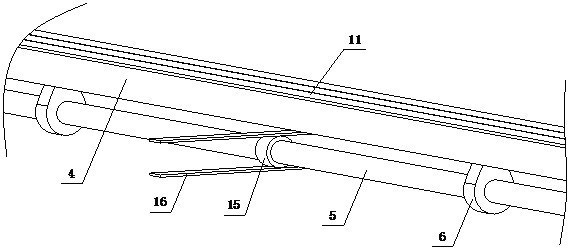

[0017] The anti-freezing device at the bottom of the compartment of a coal-transporting gondola car in the present invention is realized in the following way: the anti-freezing device at the bottom of the compartment of a coal-transporting gondola car in the present invention consists of a fixed base (2), a limiting plate (3), and a supporting base plate (4). , connecting shaft (5), cam (6), pressure block (7), support spring (8), side baffle (9), ventilation channel (10), air bag (11), air chamber (12), piston ( 13), return spring (14), transmission gear (15), transmission chain (16) and relief slot (17), a plurality of limit plates (3) are equidistantly placed on the fixed base (2), adjacent The two limiting plates (3) form a cavity, and the middle part of the limiting plate (3) has a relief groove (17), and a plurality of connecting shafts (5) are placed on the fixing seat, and the connecting The shaft (5) is correspondingly located inside the cavity, and the middle part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com