All-in-one machine for shallow plate rations

A multi-functional, all-in-one technology, which is applied to timing control of ignition mechanisms, lids of cooking utensils, kitchen utensils, etc., can solve the problems of large energy waste, single function, and can not be well adapted, and achieves superior resistance to humidity and heat. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to enable those skilled in the art to better understand the technical solutions in the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described The embodiments are only some of the embodiments of the present invention, not all of them.

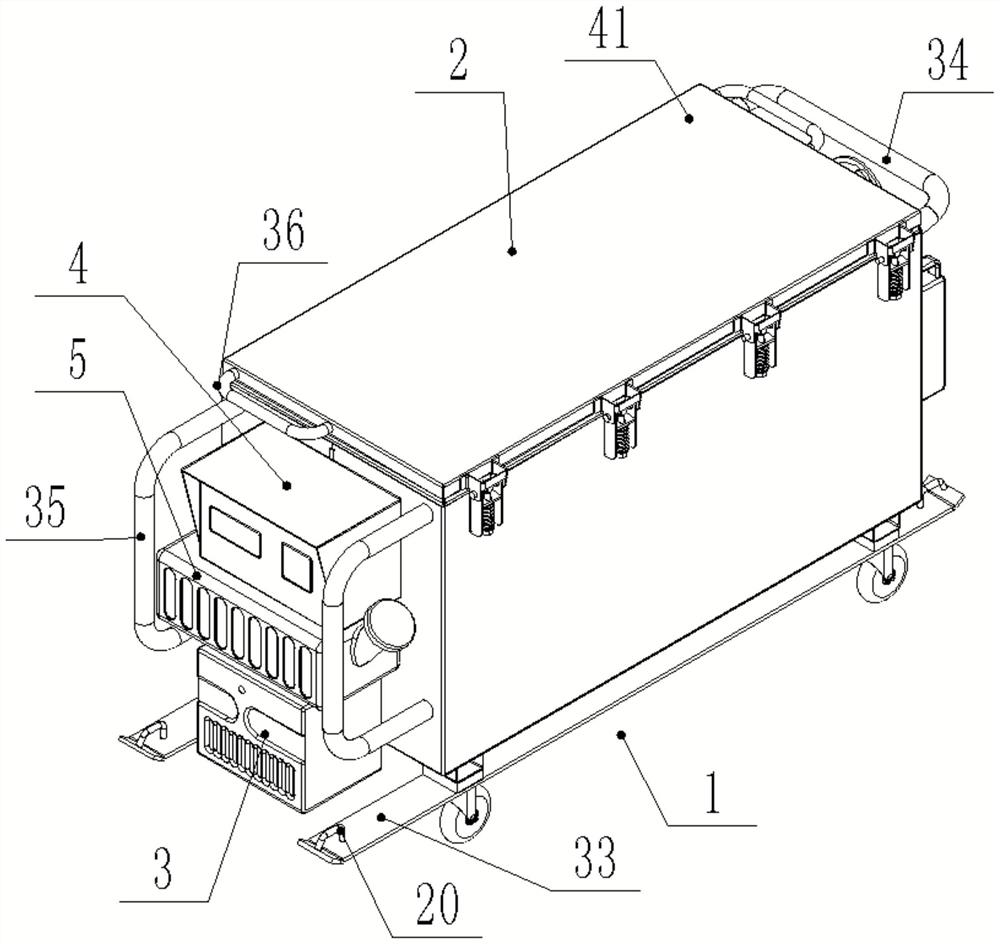

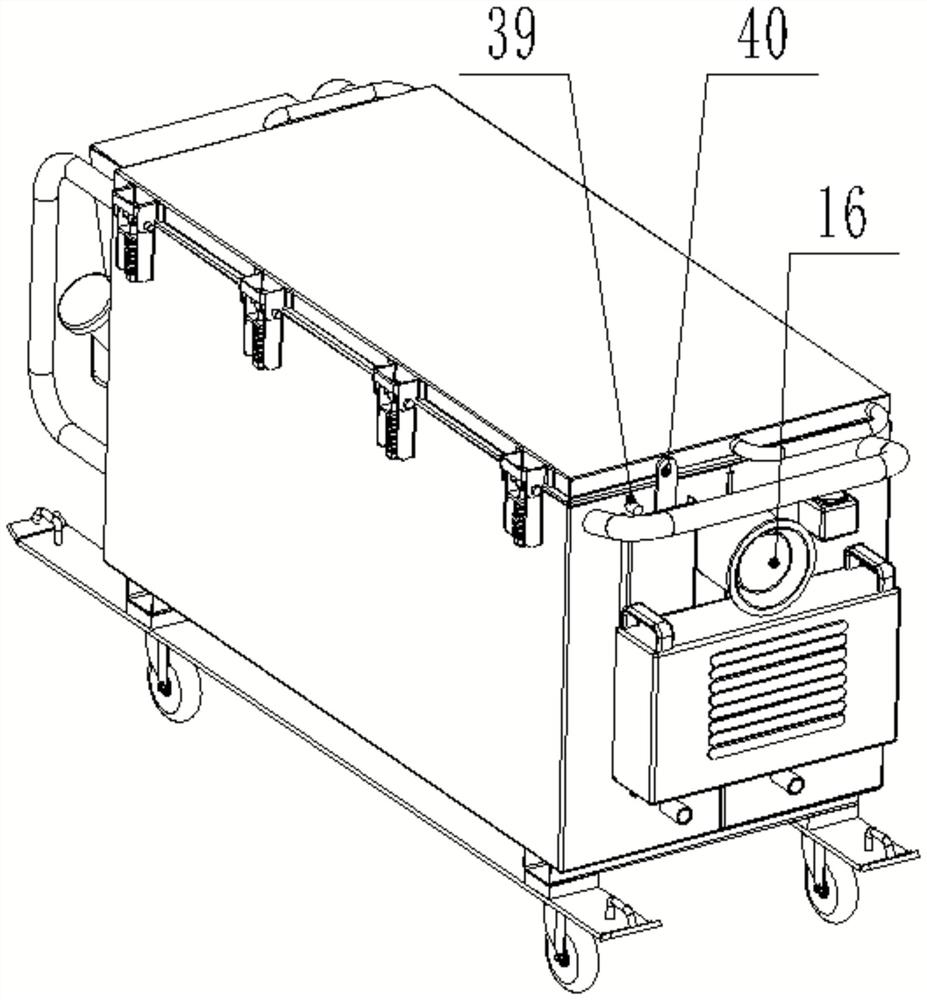

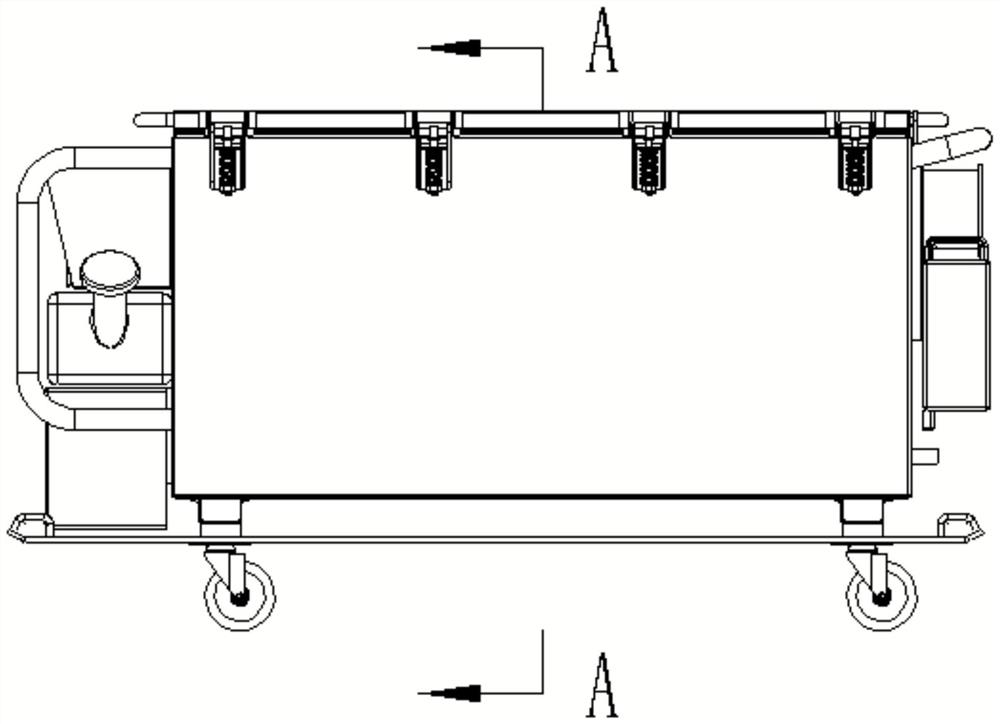

[0049] Such as Figure 1-7 As shown in the figure, a multi-functional shallow plate ration food supply machine adopts a box-type structure as a whole, including a pot body assembly, an upper cover assembly 2, a burner assembly 3, a bracket assembly 1, a power supply system, and waste heat utilization The power generation module, the perception control system, the burner assembly 3 and the pot body assembly are connected to the support assembly 1, the burner assembly 3 is installed on one side of the pot body assembly, and the smoke of the burner assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com