Anti-misoperation device in electrical intelligent manufacturing system

An anti-misoperation device and intelligent manufacturing technology, applied to electrical components, circuits, electric switches, etc., can solve problems such as input errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

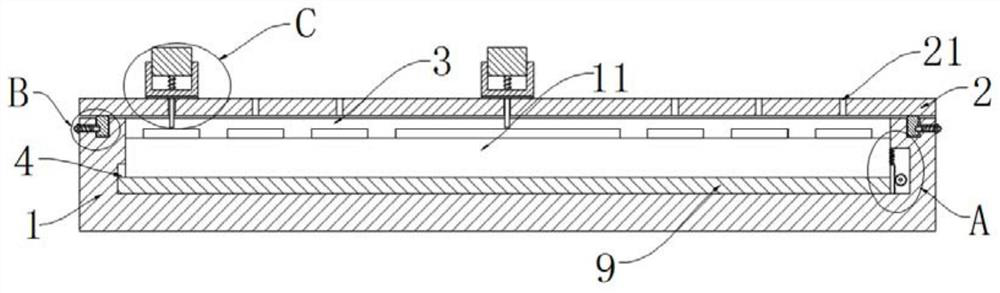

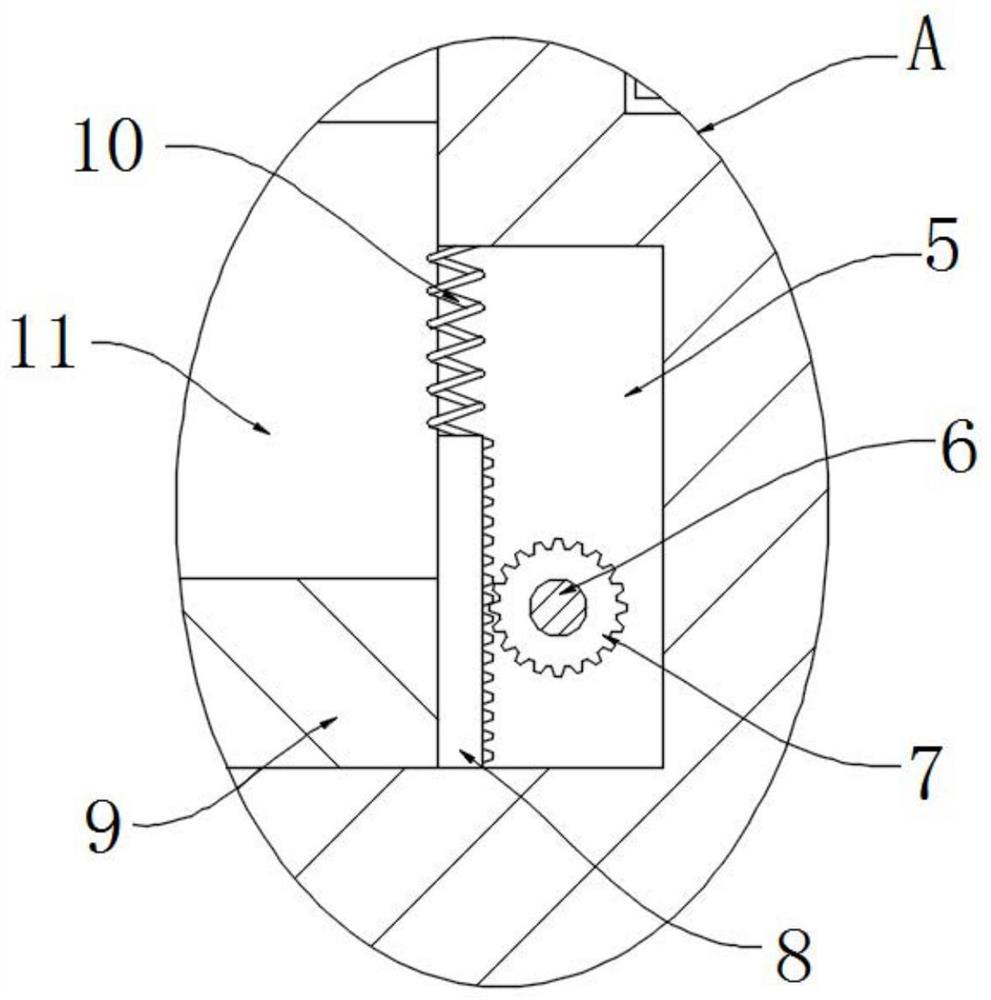

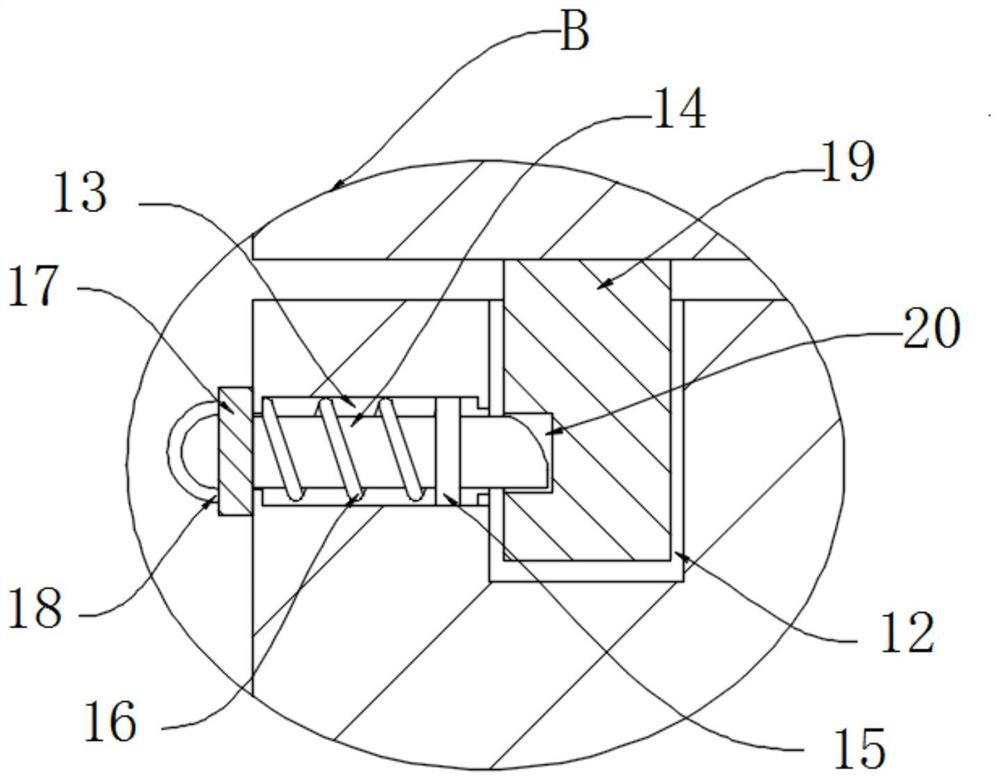

[0027] refer to Figure 1-5 , an anti-misoperation device in an electrical intelligent manufacturing system, comprising a base 1 and a cover 2, the base 1 is provided with a first groove 3, and the symmetrical side walls of the first groove 3 are respectively provided with a chute 4 and a second Groove 5 and chute 4 are used for pallet 9 to slide, while restricting the direction of motion of pallet 9 so that it can only move in the vertical direction. A rotating gear 7 is welded, and the rotating gear 7 is meshed with a rack 8, and the rack 8 is welded with a tray 9. By rotating the rotating gear 7, the rotating gear 7 meshes with the rack 8 to move, so that driven by the rack 8, the The tray 9 moves, so that the tray 9 drives the keyboard body 11 to rise to a suitable position height, the tray 9 is slidably connected with the first groove 3 through the chute 4, and the top of the rack 8 is welded with a first spring 10, the first spring 10 The other end of the tray 9 is weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com