Launching mechanism based on rigid ejector pin

A technology of launching mechanism and thimble, which is applied to launchers operated by friction wheels, weapons without explosives, throwing weapons, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

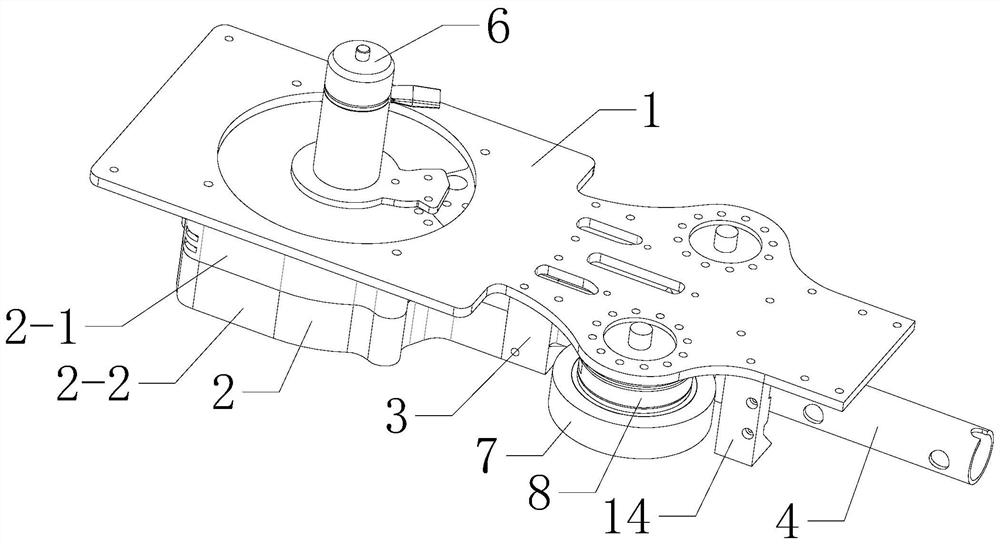

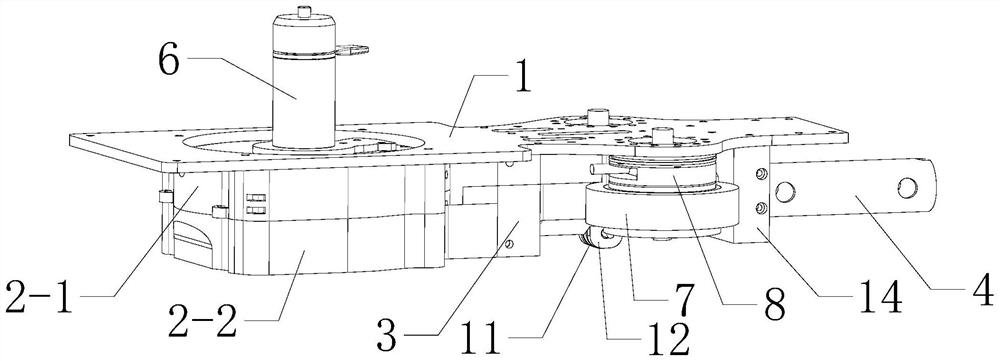

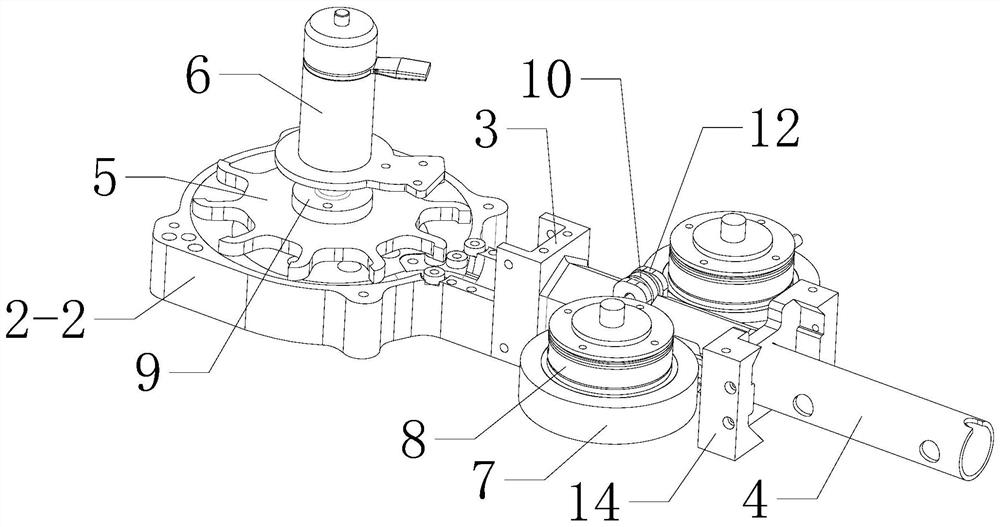

[0027] like Figure 1 to Figure 4 As shown, a launching mechanism based on a rigid thimble includes a top plate, and the bottom of the top plate is fixedly connected with a storage bin for storing elastic projectiles. Through hole, the thimble holder is connected with a launch pipeline, and the ball outlet through hole is connected with the launch pipeline; the ball storage chamber is connected with a dial for rotation, and the dial is driven by a dial motor, and the thimble holder is provided with a limit elastic projectile from launching. The limit assembly through which the pipeline passes, the left and right sides of the launch pipeline are symmetrically provided with openings, and the openings on both sides of the launch pipeline are equipped with launch friction wheels. The launch friction wheels are driven by brushless motors, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com