Integrated supporting assembly and transverse supporting structure for nuclear power steam generator

A technology for steam generators and supporting components, which is applied in nuclear power plants, nuclear power generation, detailed information of nuclear power plants, etc., and can solve problems such as difficult construction of steam generator supports, tight internal space, limited space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

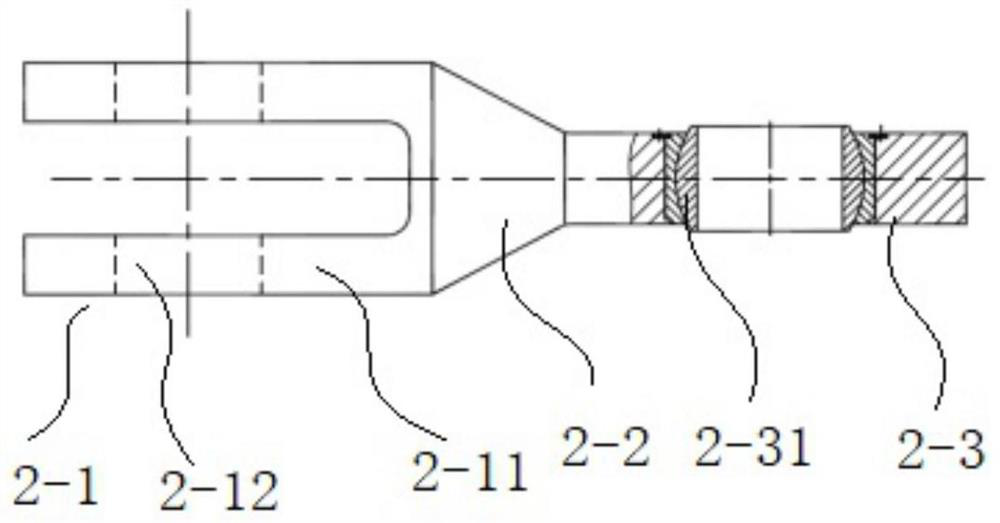

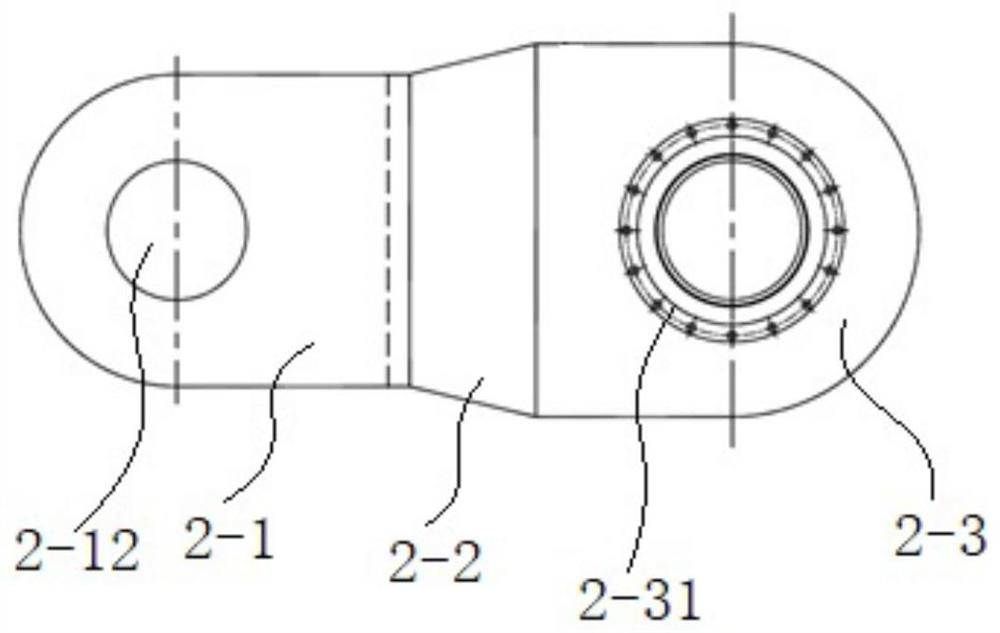

[0030] see Figure 1 ~ Figure 2 , the present invention is an integrated support assembly for nuclear power steam generators, which adopts ASTM specification material A471 CL6 forgings to mechanical processing, and the specific structure is: including an integrally connected equipment connection part, an intermediate connection part, a wall Body connecting part; among them,

[0031] The connecting part of the equipment is a U-shaped hinged joint 2-1; the two symmetrical clamping arms 2-11 of the U-shaped hinged joint are respectively provided with pin holes 2-12, which are used to pin the equipment with pins, that is, the steam generator;

[0032] The wall connection part 2-3 is in the shape of a plate as a whole, and a ball hinge hole is arranged on it, and a ball hinge 2-31 is arranged in the ball hinge hole; it is used for connecting with the wall surface connector;

[0033] The two ends of the intermediate connecting part 2-2 are respectively connected to the closed end o...

Embodiment 2

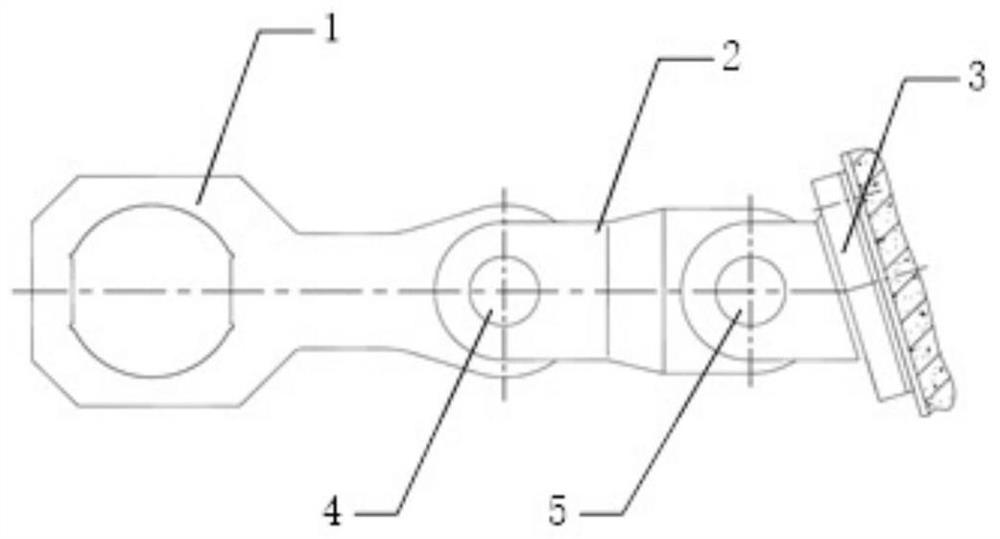

[0040] see image 3 , using the steam generator lateral support structure of the support assembly described in Embodiment 1, which includes a steam generator connection assembly 1 hinged in turn by pins, the integrated support assembly 2, and a wall support seat as a wall connector 3. Wherein, the wall support 3 includes: a connecting base 3-1 for connecting with the wall, and a wall U-shaped joint 3-2 integrally connected with the front of the connecting base 3-1. And the U-shaped joint 3-2 is obliquely connected to the base 3-1. The bottom surface of the connecting base 3-1 is assembled and connected with the body of wall.

[0041] see Figure 4 The lower part of the steam generator 6 is provided with two reactor coolant pumps 8 and vertical supports (not shown in the figure), resulting in a very tight design and installation space for the horizontal support structure of the steam generator, which must satisfy the rigid support function; It must also meet the space const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com