Steel structure assembly type beam column joint connecting device

A technology of beam-column joints and connecting devices, which is applied in the direction of building construction and construction, and can solve problems such as multiple processes and reduced construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

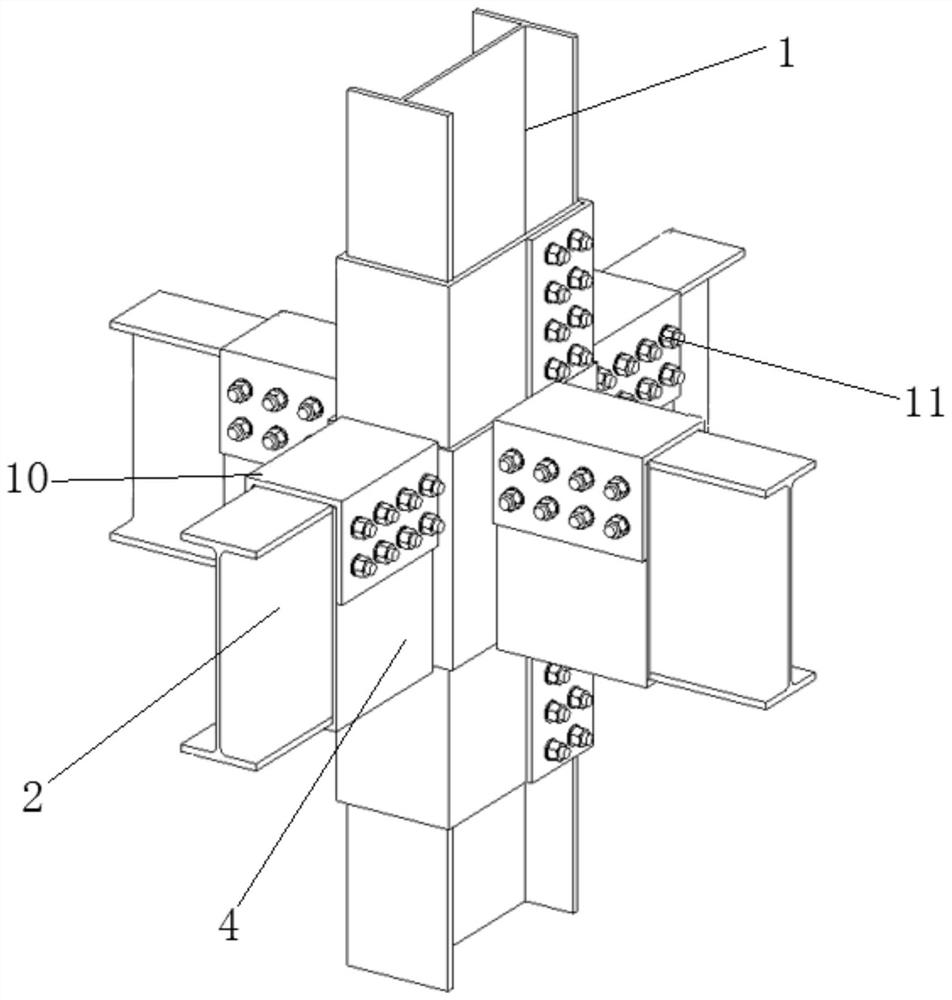

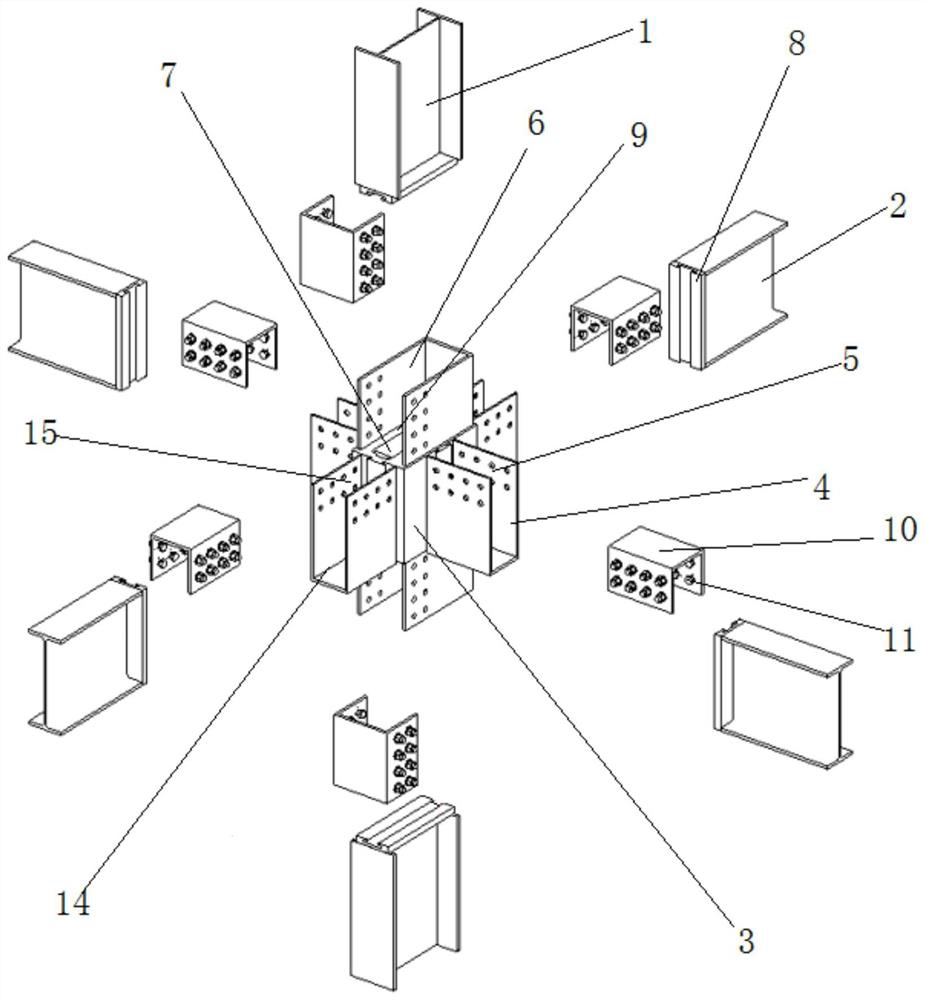

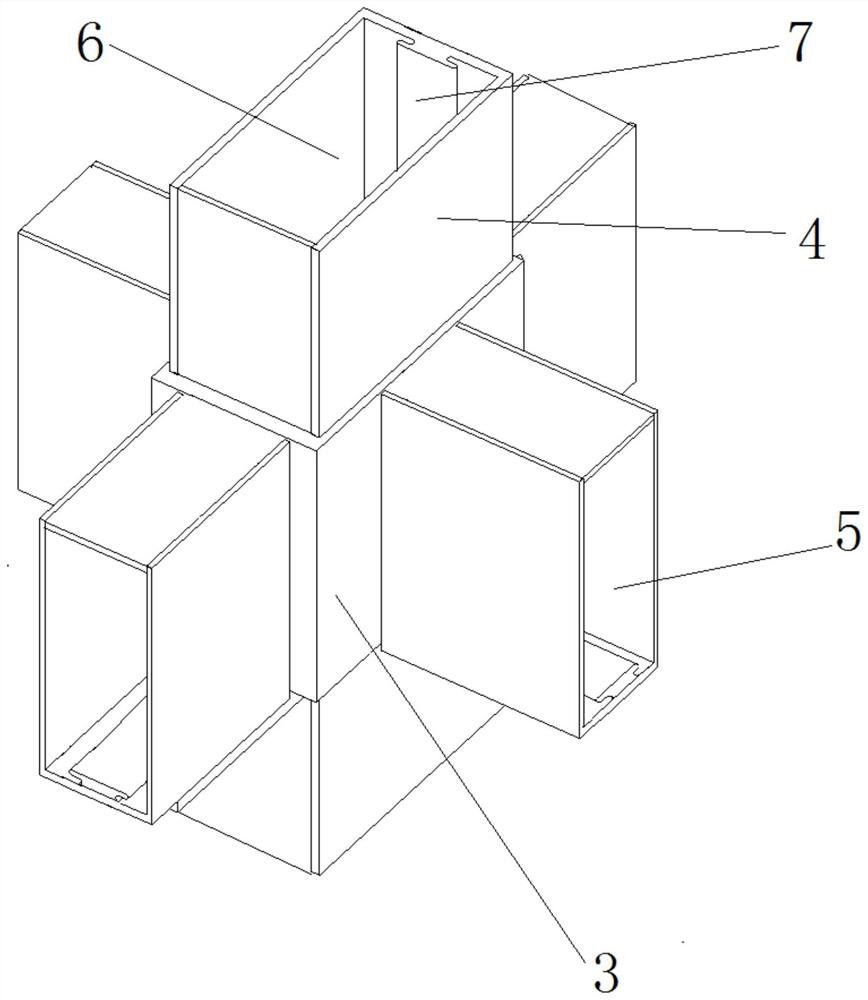

[0041] A steel structure assembled beam-column node connection device, used to connect several columns 1 and several beams 2, between the columns 1 and columns 1, between the beam 2 and the beam 2, and between the beam 2 and the beam The columns 1 are fixedly connected by a connection box 3, the connection box 3 is provided with box-shaped connectors 4 in at least two of the six directions, and at least one opening 5 is arranged on the box-shaped connector 4, so that The box-type connector 4 is provided with a guide rail 7 on at least one inner box surface 6 perpendicular to the opening 5 . Both the column 1 and the beam 2 are provided with slide rails 8 that cooperate with the guide rails 7 .

[0042] In a specific arrangement, the fixed position of the box-shaped connector 4 and the connection box 3 is the central plane 9 , and the opening 5 is at least disposed on a plane opposite to the central plane 9 . The direction of the opening 5 is determined according to the direct...

Embodiment 2

[0048] A steel structure assembled beam-column node connection device, used to connect several columns 1 and several beams 2, between the columns 1 and columns 1, between the beam 2 and the beam 2, and between the beam 2 and the beam The columns 1 are fixedly connected by a connection box 3, the connection box 3 is provided with box-shaped connectors 4 in at least two of the six directions, and at least one opening 5 is arranged on the box-shaped connector 4, so that At least one inner box surface 6 of the box-shaped connector 4 is provided with a guide rail 7 . Both the column 1 and the beam 2 are provided with slide rails 8 that cooperate with the guide rails 7 .

[0049] In a specific arrangement, the fixed position of the box-shaped connector 4 and the connection box 3 is the central plane 9 , and the opening 5 is at least disposed on a plane opposite to the central plane 9 . The direction of the opening 5 is determined according to the direction of the beam 2 or column 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com