Floor-type-free pier stud bent cap formwork dismounting and mounting equipment and construction method

A non-floor type, cover beam technology, applied in bridge construction, bridges, bridge parts, etc., can solve problems such as high risk, slow construction, poor safety and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

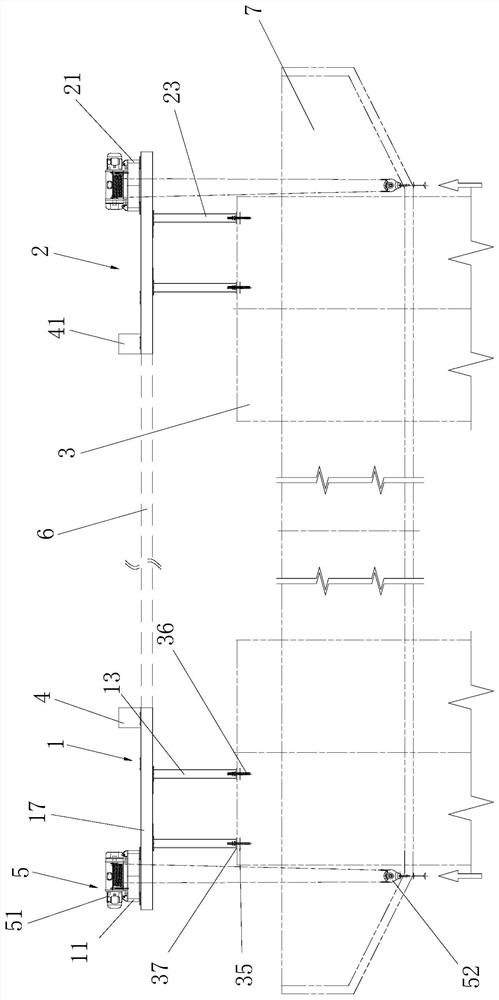

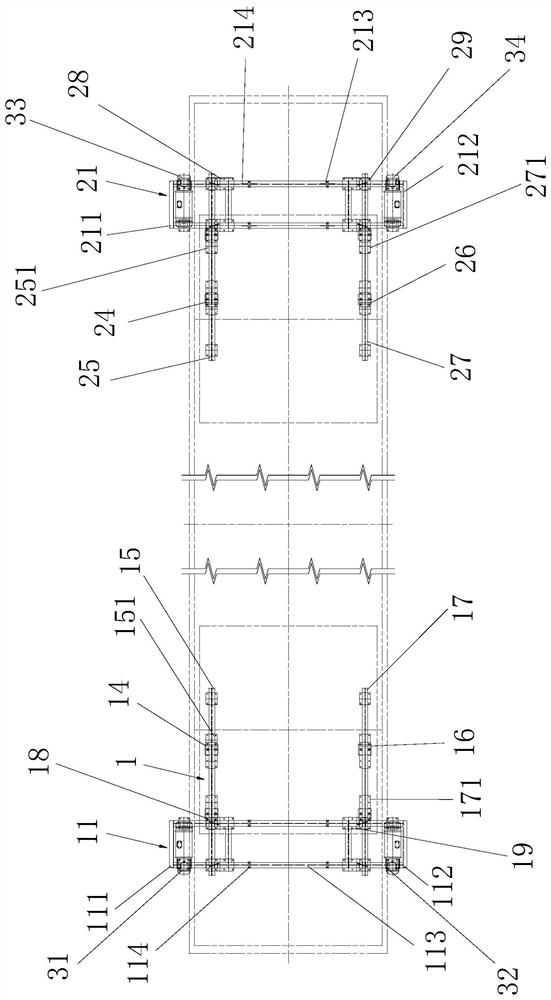

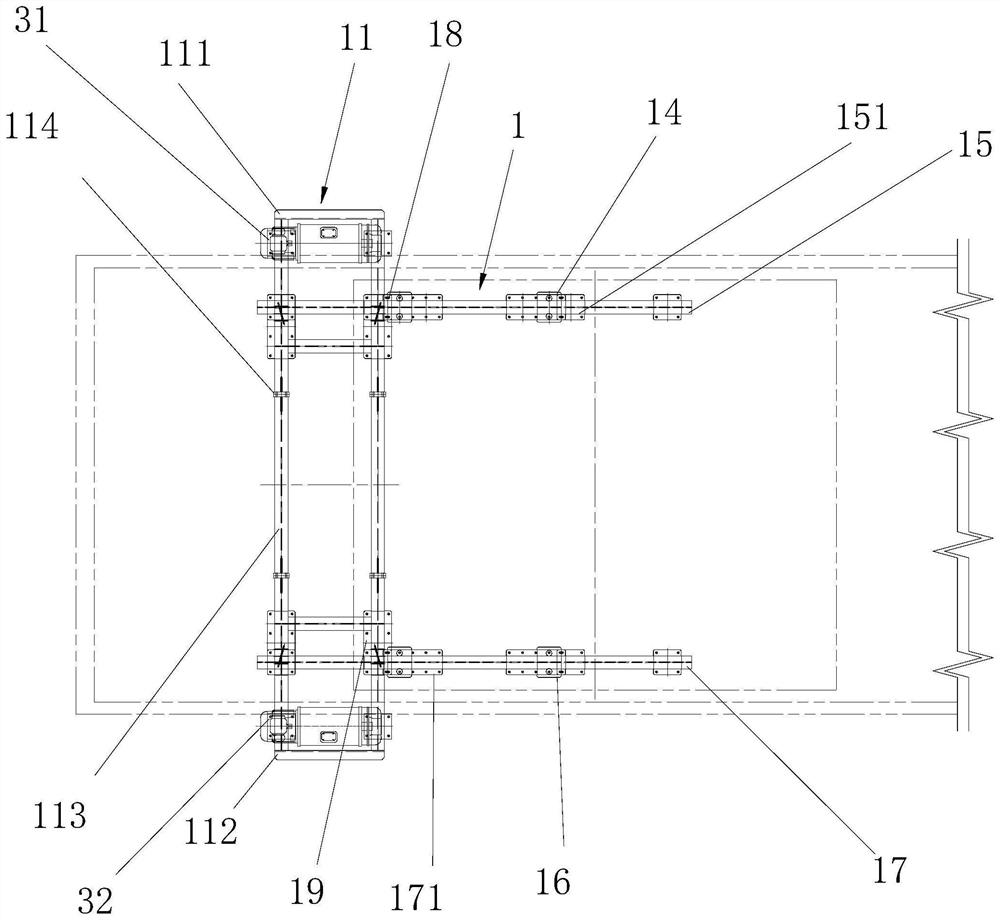

[0055] combine Figure 1 to Figure 9 , a non-floor type pier column cover beam formwork disassembly equipment, including a first support device 1 and a second support device 2, the first support device 1 and the second support device 2 are respectively arranged on two adjacent pier columns 3 the upper end. The first supporting device 1 includes a first motor support frame 11, two first legs 12 and two second legs 13, and the upper ends of the two first legs 11 are adjusted by the first transverse positioning plate 14, the first transverse positioning A first cross brace 15 is connected by bolts, and a second cross brace 17 is connected to the upper ends of the two second legs 12 through the second transverse adjustment positioning plate 16 and the second transverse positioning bolts.

[0056] The left part of the first cross brace 15 is positioned and connected with the first motor support frame 11 through the first longitudinal adjustment positioning plate 18, the first long...

Embodiment 2

[0080] combine Figure 1 to Figure 9 , a construction method of pier column cover beams, using the above-mentioned non-floor type pier column cover beam formwork disassembly equipment, specifically includes the following steps:

[0081]Step A, the first electric hoist is connected to the first front U-shaped frame through the first motor positioning base, the second electric hoist is connected to the first rear U-shaped frame through the second motor positioning base, and the first electric hoist is connected with bolts. The front U-shaped frame and the first rear U-shaped frame; the third electric hoist is connected to the second front U-shaped frame through the third motor positioning base, and the fourth electric hoist is connected to the second rear U-shaped frame through the fourth motor positioning base On the shaped frame, use bolts to connect the second front U-shaped frame and the second rear U-shaped frame;

[0082] Step B, the first motor brace is connected to the ...

Embodiment 3

[0090] In the above-mentioned non-floor type pier column cover beam formwork disassembly and assembly equipment, the main support device for formwork disassembly and assembly includes longitudinal beams, beams and legs, and each support device includes four legs, cross brace beams connected by bolts and The motor bracket fixed by bolts and positioning plates.

[0091] The support device in the present invention is a detachable connection. After the cover beam is processed, the outriggers and the cross-bracing beams are embedded in the cover beam as keels, which increases the firmness of the cover beam as a whole, avoids the trouble of later disassembly and assembly, and reduces the Construction of reinforcement frames within cap beam formwork. A 3-ton electric hoist is set on the motor support frame, and the electric hoist is fixedly connected through a flange-shaped support seat. In the two adjacent support devices, when constructing the inner steel frame of the cover beam f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com