Paving and leveling equipment for cement and concrete and paving and leveling method of paving and leveling equipment

A concrete and cement technology, applied in concrete paving and leveling equipment, cement field, can solve the problems of impurity collection at the same time, impossibility of rapid cooling of road surface, poor flexibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

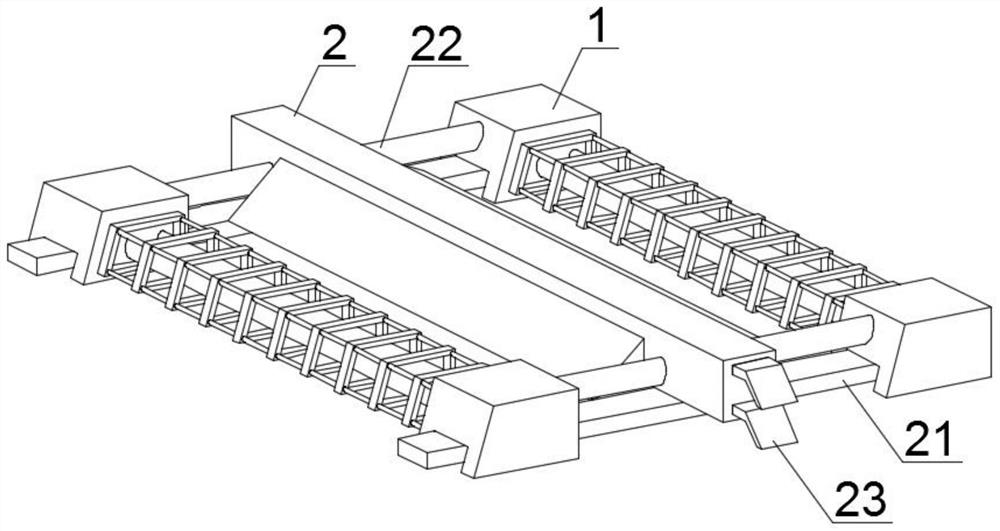

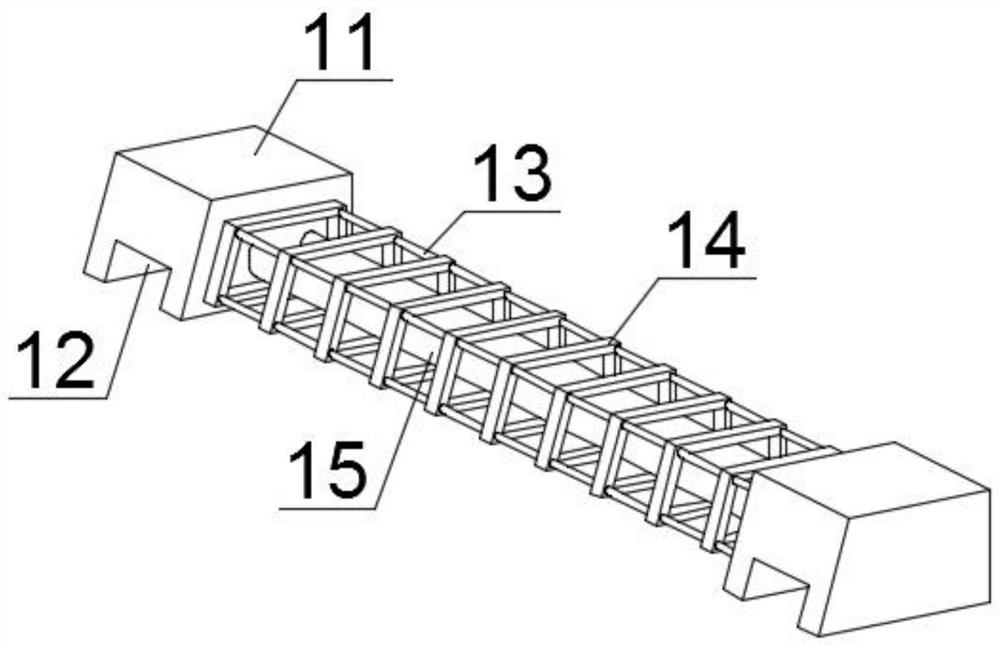

[0029] like figure 1 , 2 As shown in and 4, the paving and leveling equipment for cement and concrete includes a leveling mechanism 1 and an auxiliary mechanism 2, and the auxiliary mechanism 2 is installed between the leveling mechanisms 1, and the leveling mechanism 1 includes a stabilizing block 11, a bottom opening Slot 12, horizontally connecting adjusting rod 13, mounting frame 14 and biaxial mechanism 15, the lower end of stabilizing block 11 is provided with bottom slot 12, and horizontally connecting adjusting rod 13 is installed between stabilizing block 11, and the outside of horizontally connecting adjusting rod 13 A mounting frame 14 is installed at the end, and the inner cavity of the mounting frame 14 is provided with a biaxial mechanism 15. The biaxial mechanism 15 includes a rod body 151, an inner post 152, a mounting piece 153, an adjusting piece 154, a stabilizing shaft 155, a contact plate 156 and Embedded groove 157, the inner cavity of rod body 151 is pr...

Embodiment 2

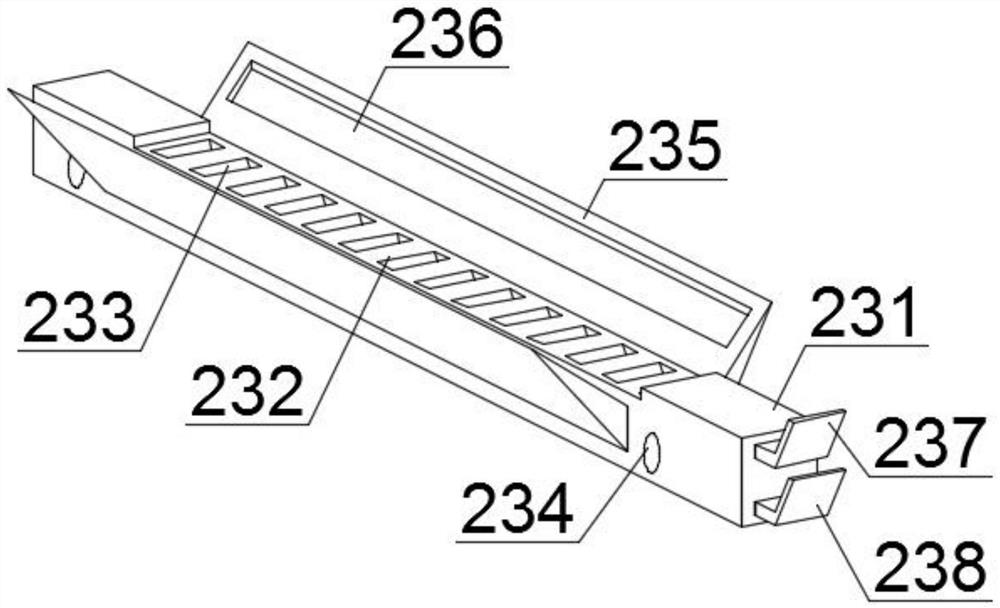

[0031] like image 3 and 5As shown, it is used for paving and leveling equipment for cement and concrete. The auxiliary mechanism 2 includes a positioning horizontal plate 21, a horizontal connecting shaft 22 and an auxiliary horizontal box 23. An auxiliary horizontal box 23 is installed above the positioning horizontal plate 21. The auxiliary horizontal box The two sides of 23 are penetratingly provided with transverse connection shaft 22, positioning transverse plate 21 comprises transverse plate frame body 211 and connecting belt 212, and horizontal plate frame body 211 is flexibly connected by connecting belt 212, and auxiliary horizontal box 23 comprises box body 231, Top slot 232, transparent exhaust cavity 233, transparent hole 234, adjustment plate 235, inner installation slot 236, bottom contact edge extension plate 237 and connecting edge extension plate 238, the bottom of the box body 231 is provided with a top opening groove 232 , the arrangement of the top slots ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com