Salinized soil roadbed construction method and salinized soil roadbed

A construction method and saline soil technology, which is applied in the field of saline soil roadbed and saline soil roadbed construction, can solve the problems of high equipment entry and exit costs, high construction cost, and complicated construction equipment, so as to ensure construction efficiency and simple construction , the effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

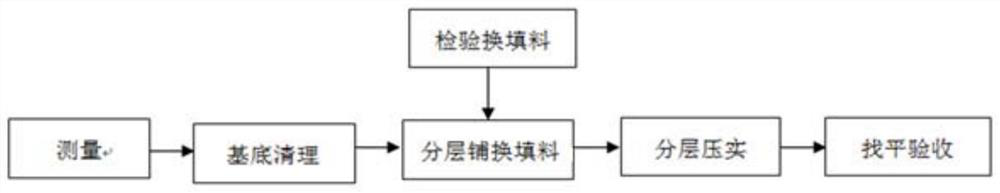

[0049] (1) According to the requirements of the design drawings, release the characteristic points of the soft foundation treatment section (starting point, end point number, width on both sides), and review the treatment width and the original surface elevation.

[0050] (2) Drain the stagnant water in the soft ground section of the salt lake road section. Before excavation, measure the necessary cross-sections, then remove the silt and flatten the bottom, such as the soft soil with large and undulating bottom area. If it is larger, steps or gentle slopes should be set up.

[0051] (3) Before replacement, conduct cross-sectional measurement and inspection and acceptance of the base.

[0052] (4) Excavate 30cm of the soft soil layer of the salt lake road section, excavate 20cm before backfilling with gravel soil, and then fill the gravel soil through two layers, each layer with a loose thickness of 30cm, and the vibration compaction density after leveling, and The settlement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com