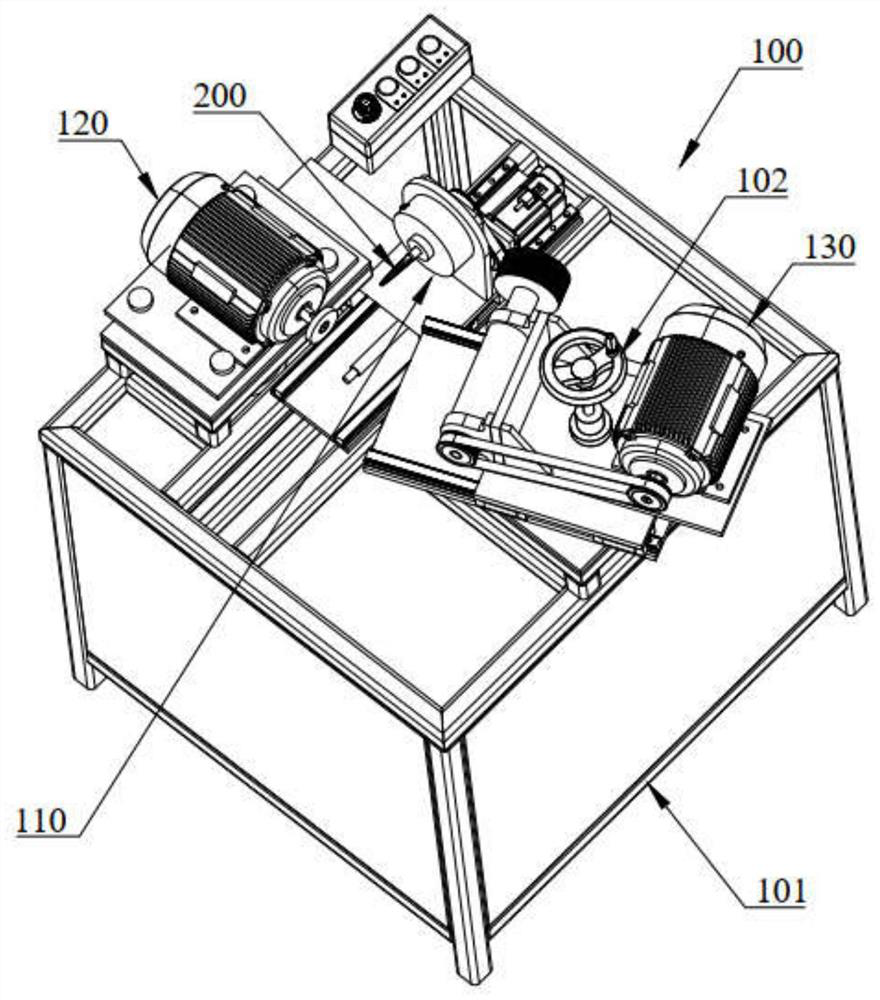

Cotton harvesting cutter grinding device

A tool grinding and grinding device technology, which is applied in the direction of grinding drive devices, cutters, grinders, etc., can solve the problems of material waste and high maintenance costs, and achieve the effect of reducing costs and avoiding cotton hooking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

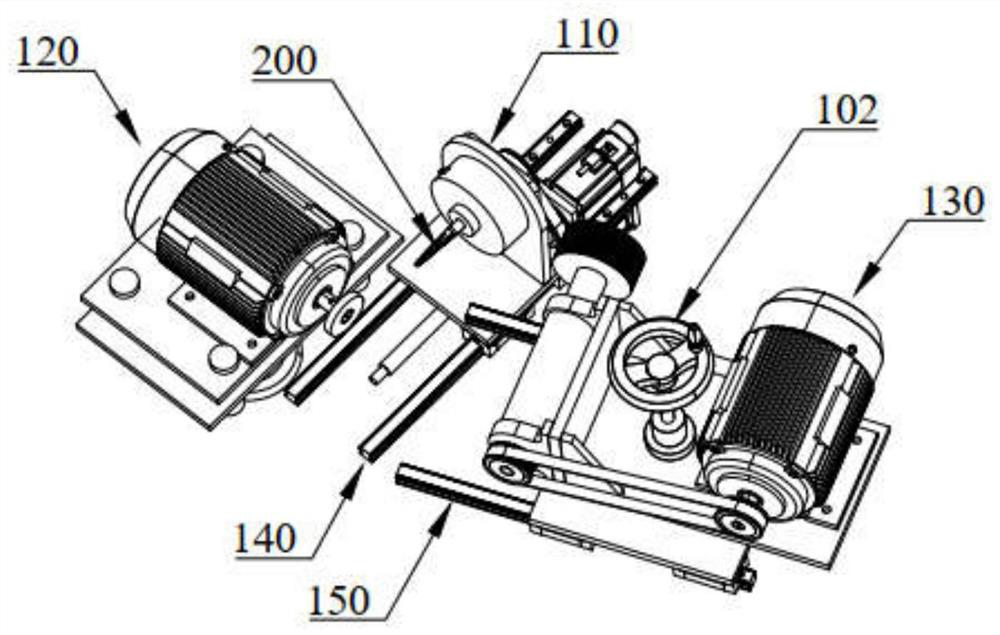

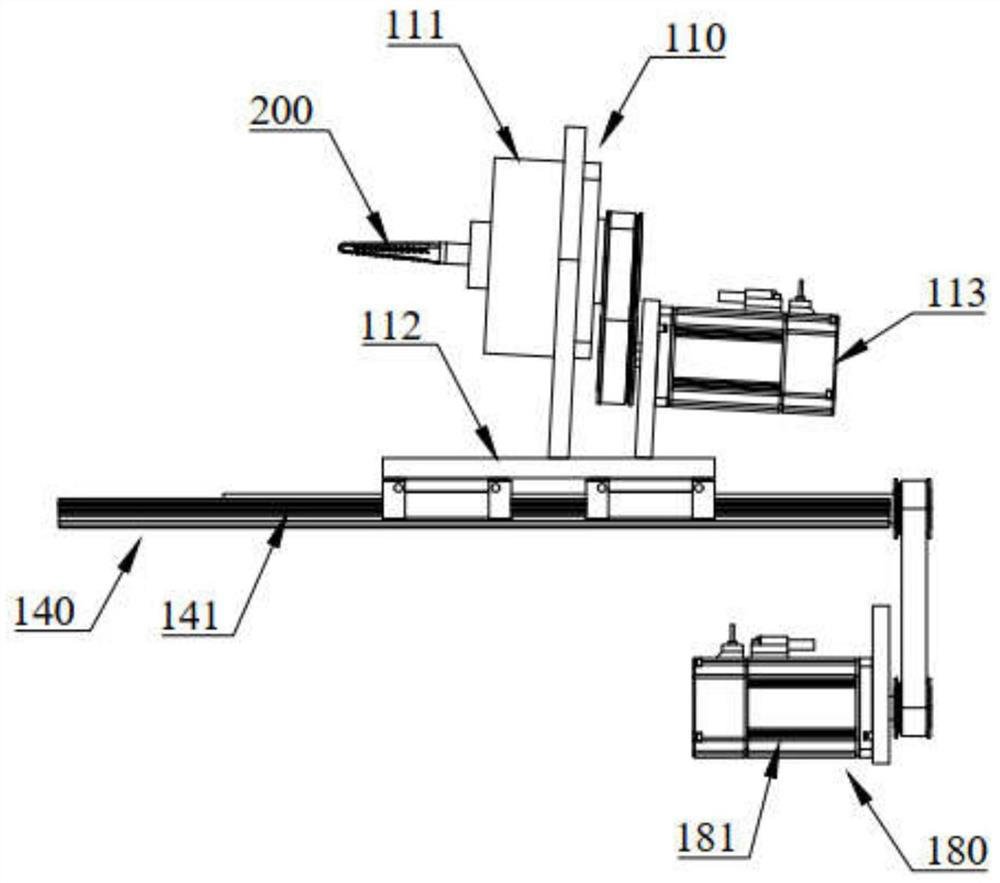

[0058] As a specific implementation manner, the cotton harvesting cutter grinding device 100 further includes: a first moving device 140 and a second moving device 150 . The first moving device 140 is used to make the first grinding device 120 and the clamping device 110 generate relative motion so as to make the first grinding wheel 121 and the cotton harvesting cutter 200 generate relative motion. The second moving device 150 is used to make the second grinding device 130 and the clamping device 110 generate relative motion so as to make the second grinding wheel 131 and the cotton harvesting cutter 200 generate relative motion.

[0059] As a specific implementation manner, the first moving device 140 includes: a first sliding rail 141 . The second moving device 150 includes: a second sliding rail 151 . The chuck seat 112 is slidably mounted on the first slide rail 141 . The chuck seat 112 slides to realize the relative movement between the chuck seat 112 and the first mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com