Optical system integrating laser paint stripping and welding

An optical system and laser paint stripping technology, applied in the field of optical systems, can solve the problems of fragile coils, inductive coil damage, low yield rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

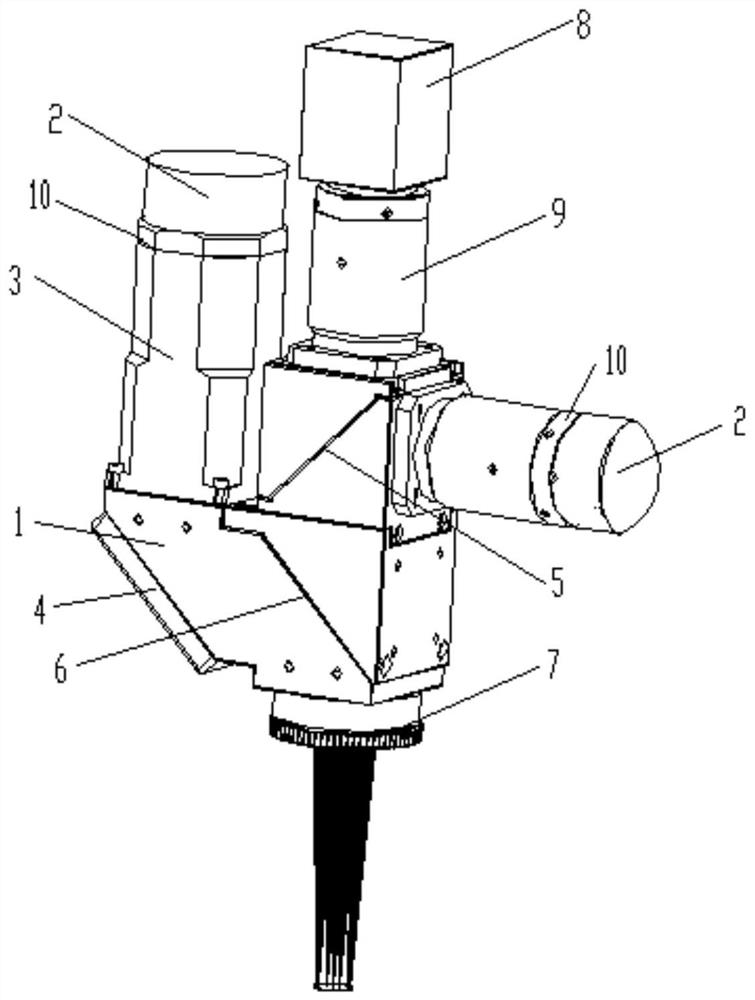

[0035] On the basis of the above-mentioned structure, in the present embodiment, the reflection assembly includes a total reflection mirror 4, a reflection mirror 5 and a light combining mirror 6, and the total reflection mirror 4 is tilted by means that those skilled in the art can think of such as gluing or bolting. The position below the corresponding input port 1 in the mounting seat 1 is used to reflect the laser beam input from the input port 1; the reflective mirror 5 is tilted and installed on the mounting seat 1 by means that those skilled in the art can imagine such as gluing or bolting The position close to the upper end of the mounting base 1 is used to reflect the laser beam input from the input port 2; the light combining mirror 6 is tilted and installed in the mounting base 1 by means that those skilled in the art can think of, such as gluing or bolting. The position of the lower end of the seat 1, and parallel to the total reflection mirror 4, is used to respect...

Embodiment 2

[0037] On the basis of Embodiment 1, in this embodiment, the mounting seat 1 is an L-shaped seat, the lower end of the vertical part is fixedly connected and communicated with one end of the horizontal part, and the lower through hole is located at the lower end of the vertical part; Formed integrally with the horizontal section. The first input port is located on the upper side of the other end of the horizontal part, and the second input port is located on one side of the upper end of the vertical part. The scheme is simple in structure, reasonable in design, convenient to install various components without mutual influence, and convenient to use.

Embodiment 3

[0039] On the basis of Embodiment 2, in this embodiment, the lower side of the other end of the horizontal part is slope-shaped and open, and the total reflection mirror 4 is fixedly installed on the open part of the horizontal part. The structure is simple, the design is reasonable, and it is convenient to install each part.

[0040] The reflecting mirror 5 and the light combining mirror 6 are located in the upper end and the lower end of the vertical portion respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com