Equipment for assisting in repairing damaged pipeline

A technology for repairing pipes and pipes, applied in auxiliary welding equipment, welding/cutting auxiliary equipment, auxiliary devices, etc., can solve problems such as poor welding quality, difficult labor, and easy water leakage at welding places, so as to improve repair accuracy and avoid measurement Error, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

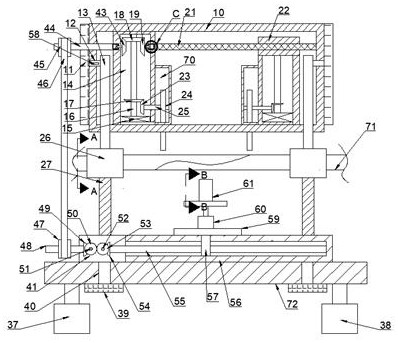

[0017] Combine below Figure 1-4 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

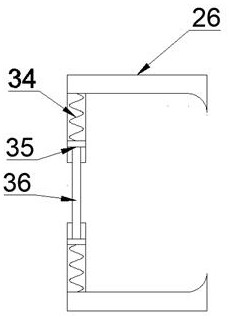

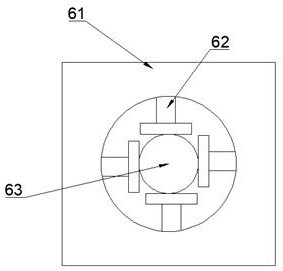

[0018] A device for auxiliary repair of damaged pipelines described in conjunction with accompanying drawings 1-4, includes a main body 10, a power chamber 14 is fixed inside the main body 10, a motor 15 is fixed inside the power chamber 15, and the motor 15 A motor shaft 16 is rotatably provided on the top, a first bevel gear 17 is fixedly provided on the motor shaft 16, a second bevel gear 18 is fixedly provided on the motor shaft 16, and a rotatable device on the power chamber 14 There is a first rotating shaft 20, a power adjustment box 28 is arranged inside the first rotating shaft 20, a first electromagnet 33 is fixed inside the power adjustment box 28, and a first electromagnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com