Automatic production line model information verification system

A technology for automatic production line and information verification, applied in the field of automatic production line model information verification system, which can solve problems such as difficult problem tracing, bar code information error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] A further detailed description will be made below in conjunction with the accompanying drawings and embodiments of the present invention:

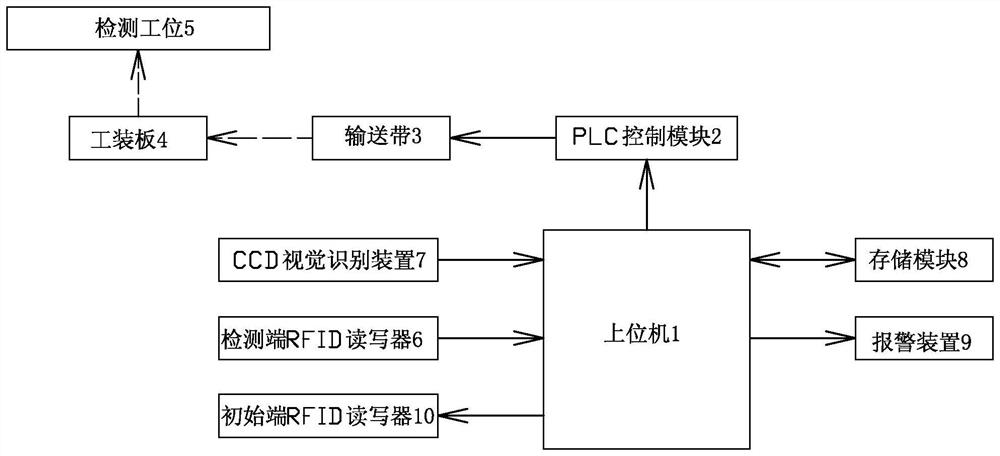

[0014] Such as figure 1 As shown, an automated production line model information verification system includes a host computer 1 with preset model information, energy consumption post information of the corresponding model, nameplate information of the corresponding model, and barcode information of the corresponding model. 1 is connected with the PLC control module 2, and the PLC control module 2 is connected with the conveyor belt 3, and the conveyor belt 3 is provided with a tooling plate 4 and a testing station 5 for placing the detection products, and the tooling plate 4 is equipped with a storage The RFID card with equipment model information, the upper computer 1 is connected with the detection terminal RFID reader 6 set on the detection station 5 for reading the equipment model information in the RFID card and the energy cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com