Dust removal equipment for feed processing

A technology for dust removal equipment and feed processing, which is applied in the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

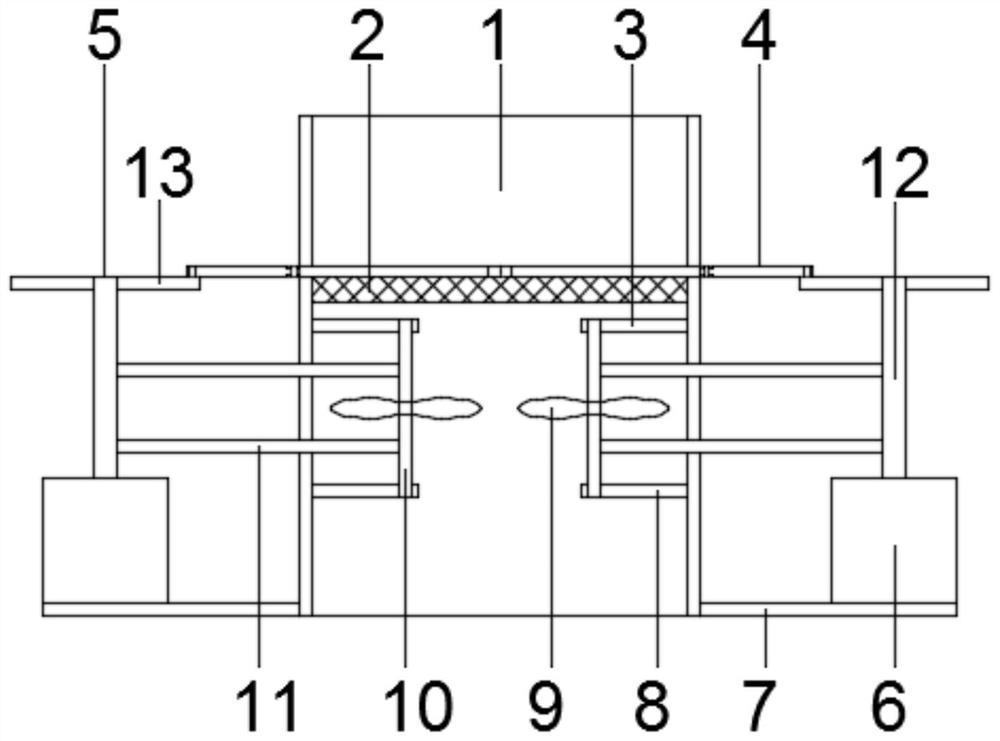

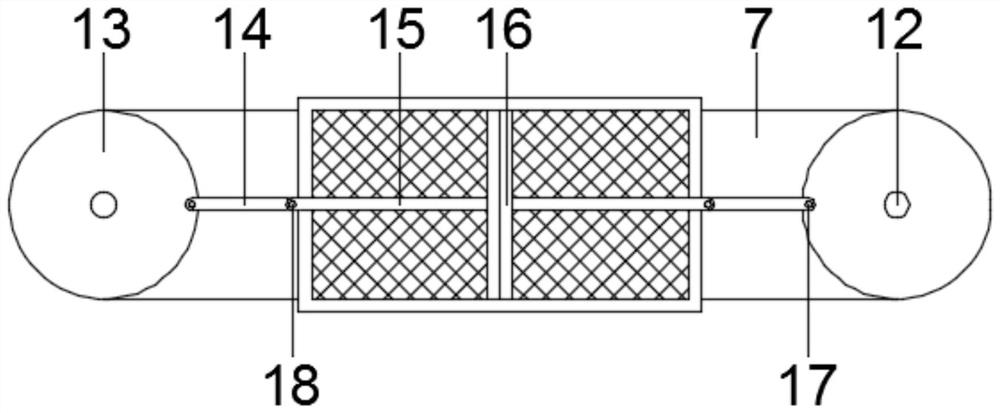

[0022] Such as figure 1 , 2 The shown dust removal equipment for feed processing includes a dust removal cylinder 1, a filter plate 2 is fixedly installed in the dust removal cylinder 1, a blower mechanism 3 is installed on one side of the filter plate 2, and a filter plate cleaning mechanism 4 is installed on the other side The outer side of the dust removal cylinder 1 is fixedly installed with a drive mechanism 5 for driving the blower mechanism 3 and the filter plate cleaning mechanism 4 to work, that is, the drive mechanism 5 is set to work with the blower mechanism 3 to filter the waste gas through the filter plate 2 and then discharge it. At the same time, the filter plate cleaning mechanism 4 is used to clean the filter plate 2, thereby effectively preventing the filter plate 2 from clogging and affecting the dust removal efficiency.

[0023] Further, the drive mechanism 5 includes a drive motor 6, and a motor mounting plate 7 fixedly connected to it is installed on th...

Embodiment 2

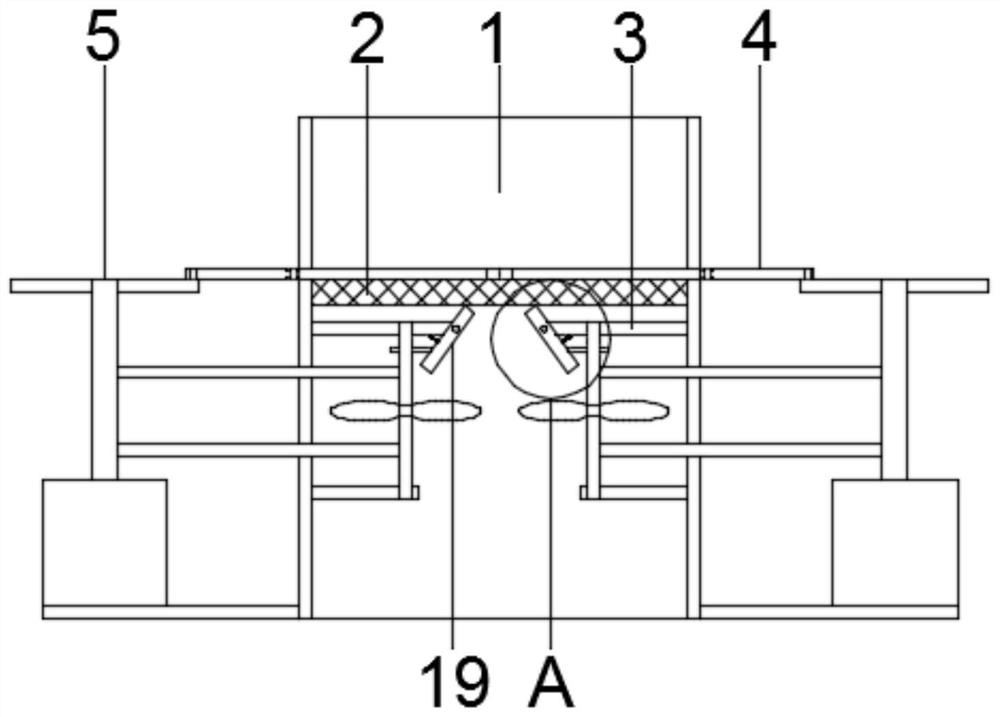

[0026] This embodiment is further optimized on the basis of Embodiment 1. A vibration mechanism 19 is installed on the blowing mechanism 3, that is, the filter plate 2 is knocked by the vibration mechanism 19, thereby further improving the cleaning effect. Specifically, the vibration Mechanism 19 includes a vibrating rod 21, which is arranged on the fan support 8 and is rotatably connected to it. A spring 22 fixedly connected to it is installed at the bottom of the vibrating rod 21. The end of the spring 22 away from the vibrating rod 21 is connected to the fan support. 8 is fixedly connected, and the outer fixed sleeve of the synchronous shaft 10 is provided with a cam 23 that matches the vibrating rod 21, that is, the synchronous shaft 10 rotates synchronously with the cam 23 when it rotates, and the lower end of the vibrating rod 21 is caused by the action of the spring 22 to make it The upper end is separated from the filter plate 2. When the cam 23 rotates to make the conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com