Automatic feeding system and method and medium

A technology of automatic feeding and material, applied in manufacturing computing systems, data processing applications, comprehensive factory control, etc., can solve problems such as material and order mismatch, material loss or damage, low material transmission efficiency, etc., to improve accuracy sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

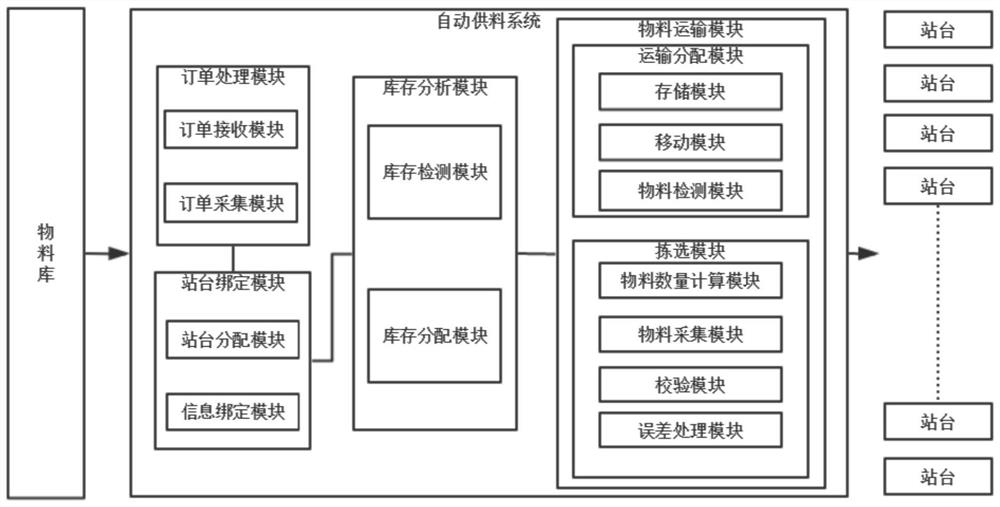

[0051] This embodiment provides an automatic feeding system, such as figure 1 shown, including:

[0052] Order processing module, platform binding module, inventory analysis module and material transportation module;

[0053] In this embodiment, between the automatic feeding system setting and the material warehouse and the platform, an EPR system is provided on the material warehouse, which is used to receive orders. The order processing module is equipped with a WMS system, and the WMS system is equipped with corresponding control systems. Interface, the WMS system realizes the operation of the entire automatic feeding system through the operation of code instructions and control interface; the platform binding module, inventory analysis module and material transportation module are equipped with WCS system, and the WCS system drives each module to realize the corresponding functions;

[0054] The order processing module includes an order receiving module and an order colle...

Embodiment 2

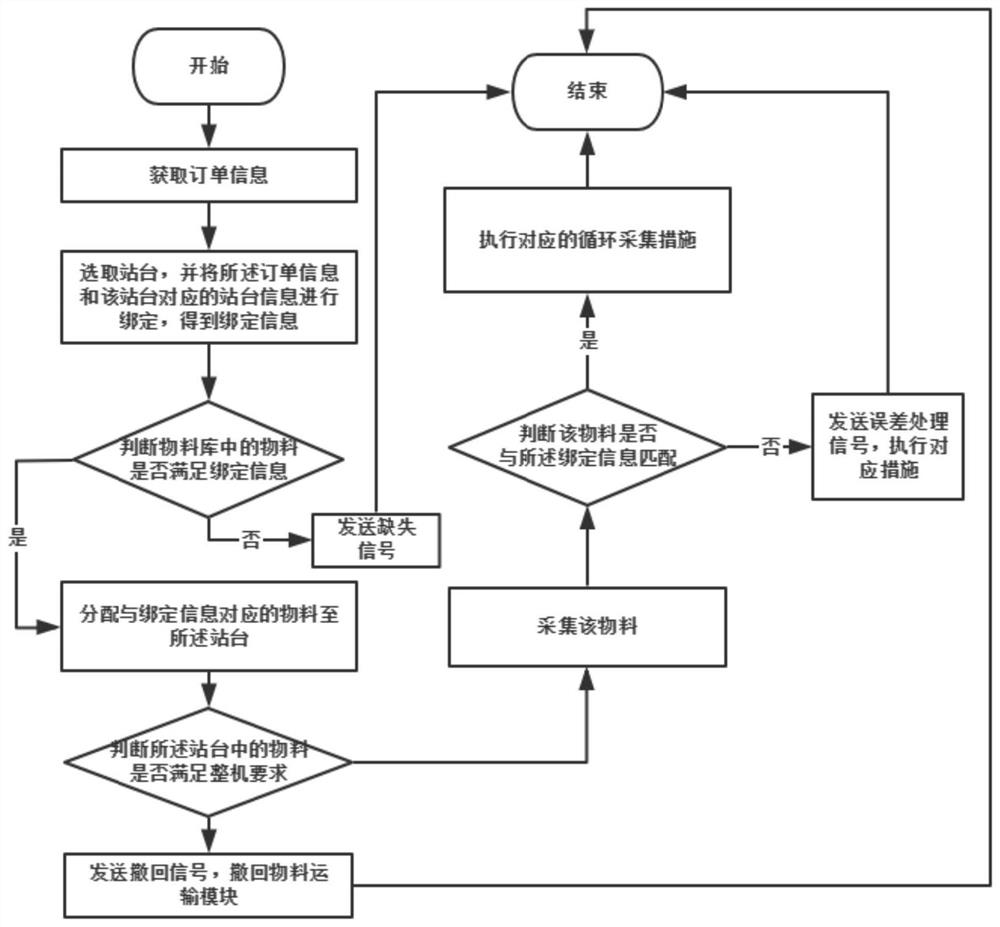

[0083] Based on the same inventive concept as the automatic feeding system described in Embodiment 1, this embodiment also provides an automatic feeding method, such as figure 2 shown, including:

[0084] Obtain order information; select a platform, and bind the order information with the platform information corresponding to the platform to obtain binding information; determine whether the materials in the material library meet the binding information, and if so, allocate and bind information The corresponding material is sent to the platform; judge whether the material in the platform meets the requirements of the whole machine, if so, collect the material, and determine whether the material matches the binding information, and if it matches, execute the corresponding cycle collection measures.

[0085] Based on the same inventive concept as the automatic feeding method in the foregoing embodiments, the embodiment of this specification also provides a computer-readable sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com