Kitchen heavy oil stain cleaning agent as well as preparation method and application thereof in aerosol

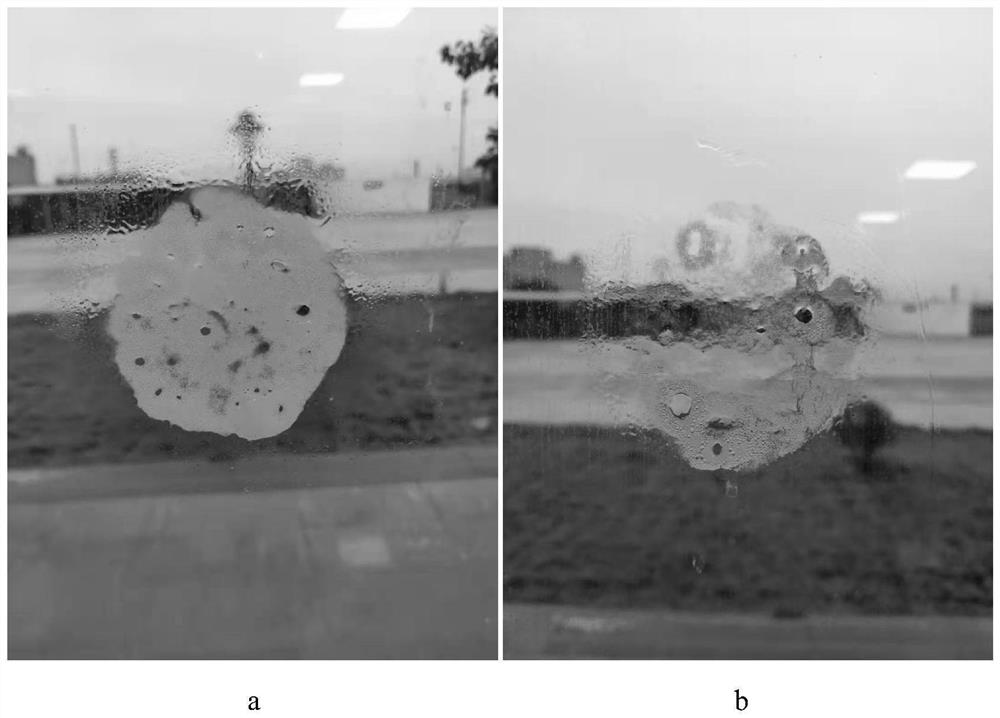

A heavy oil stain cleaning agent and aerosol technology, applied in the field of cleaning agents, can solve the problems of reducing the contact area between the active ingredient and the oil stain surface, poor cleaning effect of heavy oil stains, and insufficient contact, etc., to solve the problem of strong alkali Corrosion problem, good water solubility, easy cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A kind of preparation method of kitchen heavy oil dirt cleaning agent aerosol, production process is as follows:

[0047] Preparation of liquid A:

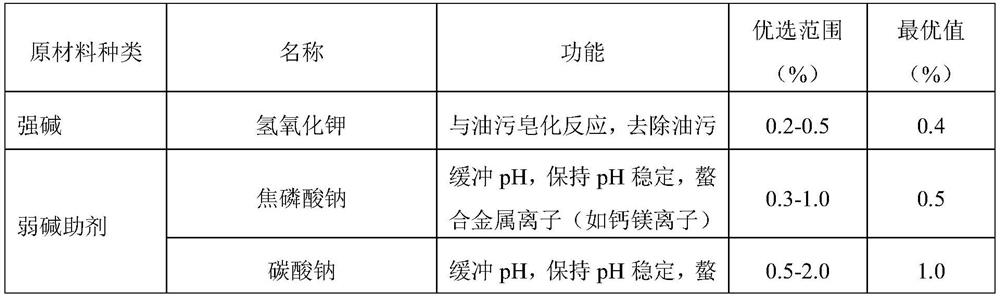

[0048] 1. Add potassium hydroxide, sodium pyrophosphate, sodium carbonate, organic borate, sodium benzoate, sodium metasilicate, and fruit essence into deionized water, stir to dissolve, stir for 5 minutes, control the temperature at 30°C, and stir at 1500 rpm / s.

[0049] 2. Add lithium magnesium silicate into 1, and dissolve while stirring. The stirring time is 15 minutes, the temperature is controlled at 30°C, and the stirring speed is 500 rpm / s.

[0050] 3. After dissolving, let stand for 15 hours to form a gel.

[0051] Preparation of liquid B:

[0052] 1. Add N,N-dimethyl 9-decenamide, isohexanediol, ethylene bis(dodecyl amidopropyl dimethyl ammonium chloride), propylene bis(hexadecanoyl propyl dimethyl ammonium chloride), polyolefin-based quaternary ammonium salt, and cocamidopropyl betaine were stirred and mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com