Rubber preforming device

A pre-forming, rubber technology, applied in the field of rubber manufacturing, can solve the problems of weight difference of rubber blocks, poor cutting effect of a single cutter, troublesome use, etc., to achieve the effect of speeding up the cooling rate, convenient and fast precise cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

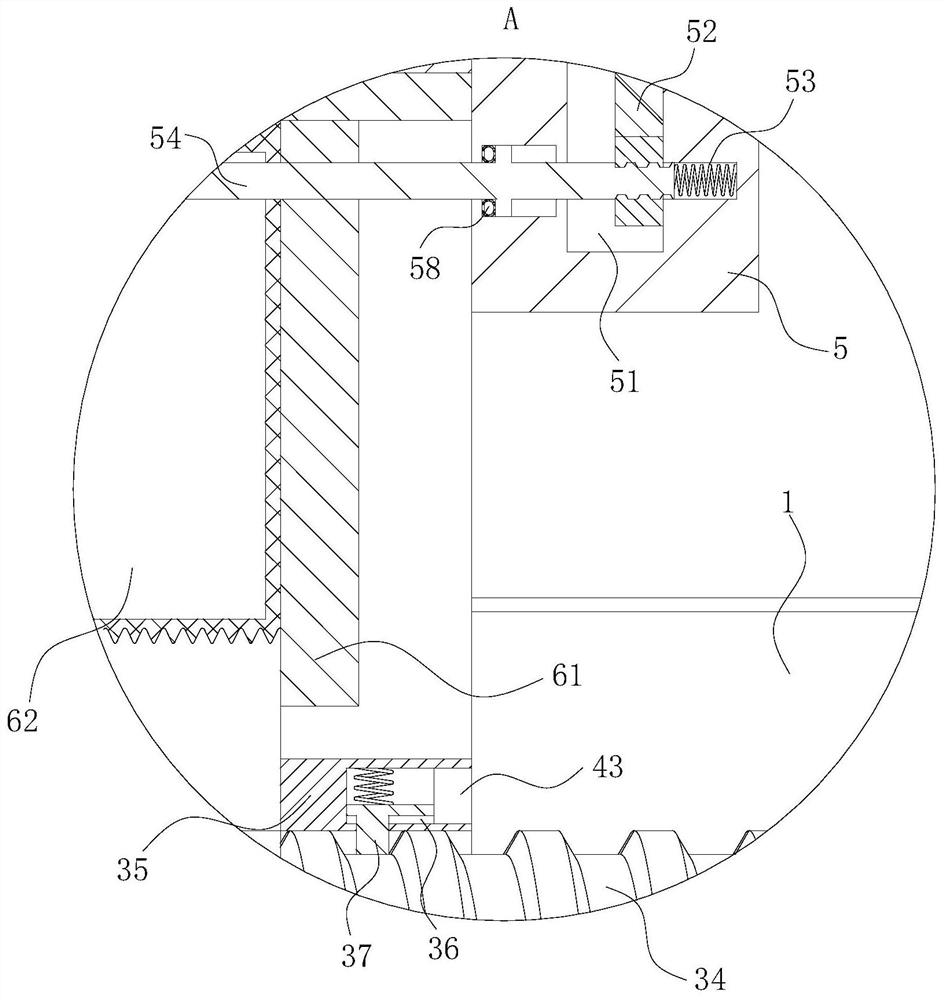

[0028] As an embodiment of the present invention, both sides of the cutting groove 51 are fixedly connected with a scraper 56; the scraper 56 is made of elastic metal sheet material; the scraper 56 and the end of the cutting groove 51 away from the hinge point It is elastically connected by a spring; the scraper 56 is fixedly connected with an expansion bag 57 on the side close to the inner wall of the cutting groove 51; The extruding capsule 58 and the expansion capsule 57 are designed to be connected; during work, when the push rod 54 moves to the inside of the first channel 53, the shape of the extrusion capsule 58 becomes larger, and then the extrusion capsule 58 forms a negative pressure, so that the expansion capsule 57 shrinks, and then the scraper 56 is close to the direction of the side wall of the cutting groove 51, so that the cutting of the cutting knife 52 by the baffle will not be hindered, and when the push rod 54 rebounds and resets, the squeeze bag 58 will diss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com