Semi-flexible multi-finger manipulator based on soft steel belt and toroidal worm and control method

A toroidal worm, mild steel belt technology, applied in the direction of manipulators, manufacturing tools, chucks, etc., can solve the problems of limited grasping target shape, increased processing cost, large application, etc., to achieve flexible clamping and stable handling, Safe and reliable transportation, stable and reliable grasping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

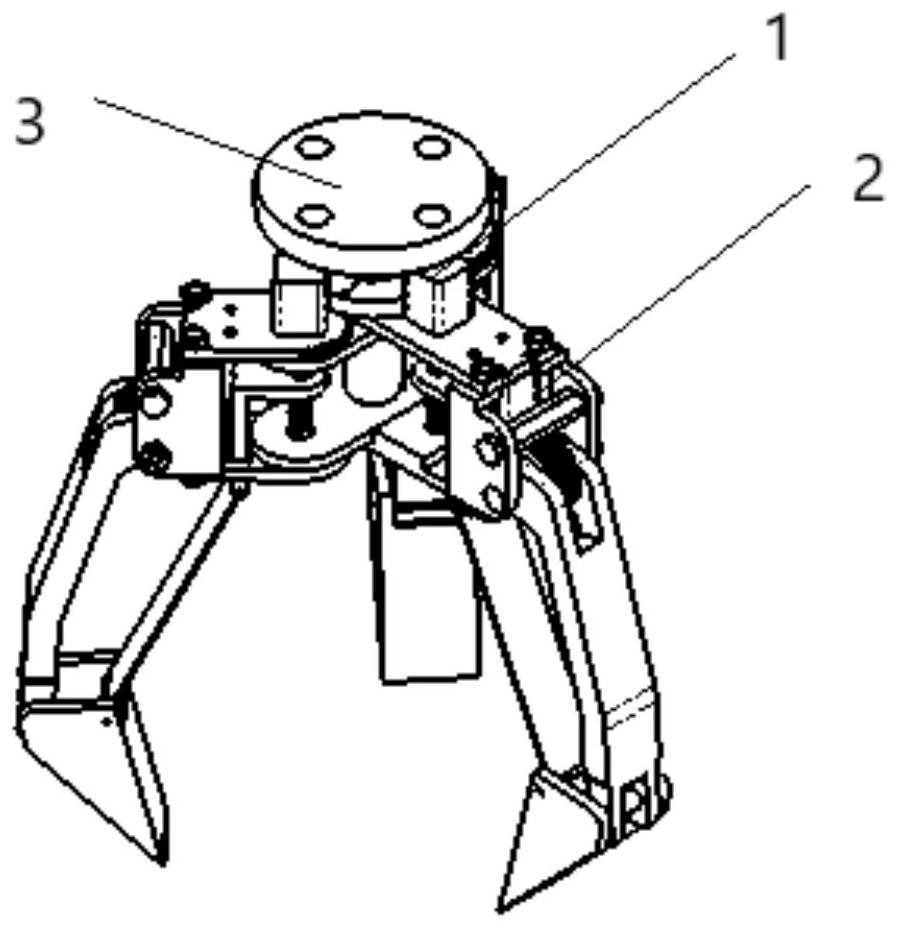

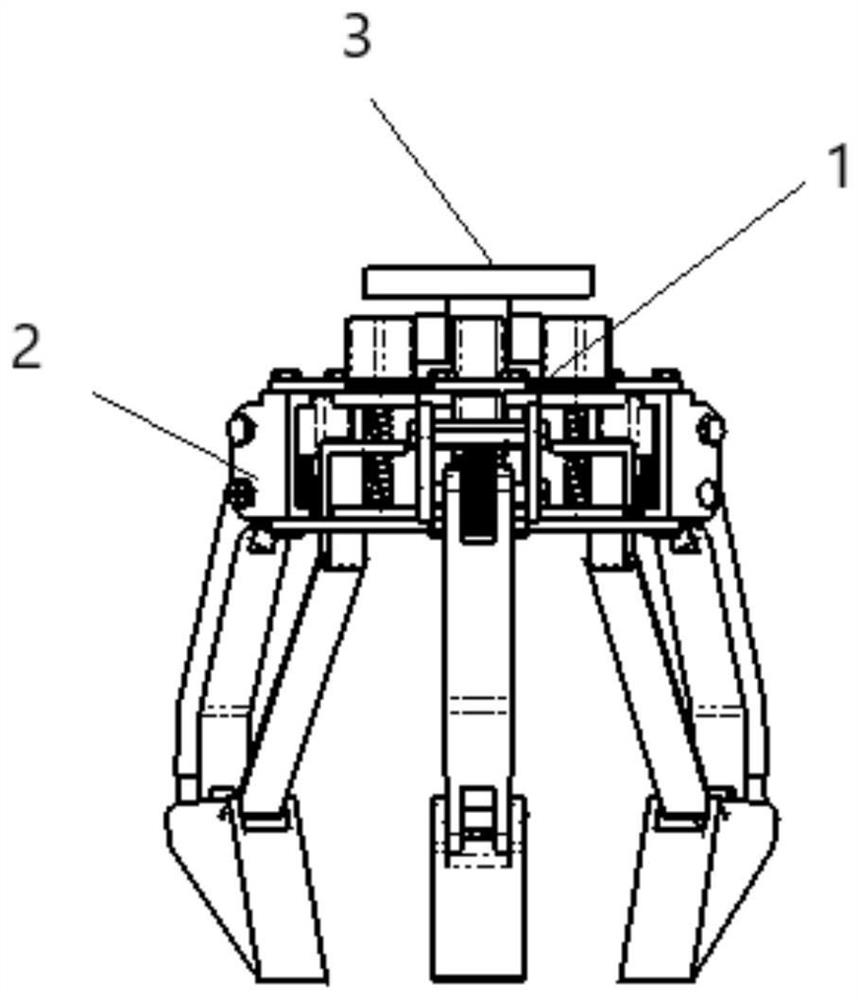

[0077] Embodiment 1 A kind of semi-flexible multi-fingered manipulator based on mild steel belt and toroidal worm according to the present invention includes:

[0078] The bracket unit 1 includes a main bracket 11 and a side bracket 12, the outside of the main bracket 11 is provided with a mounting area for installing the grab unit; the side bracket 12 is fixed on the inside of the main bracket, and the side bracket is provided with a plurality of extending outward to form a connecting end for installing the grabbing unit;

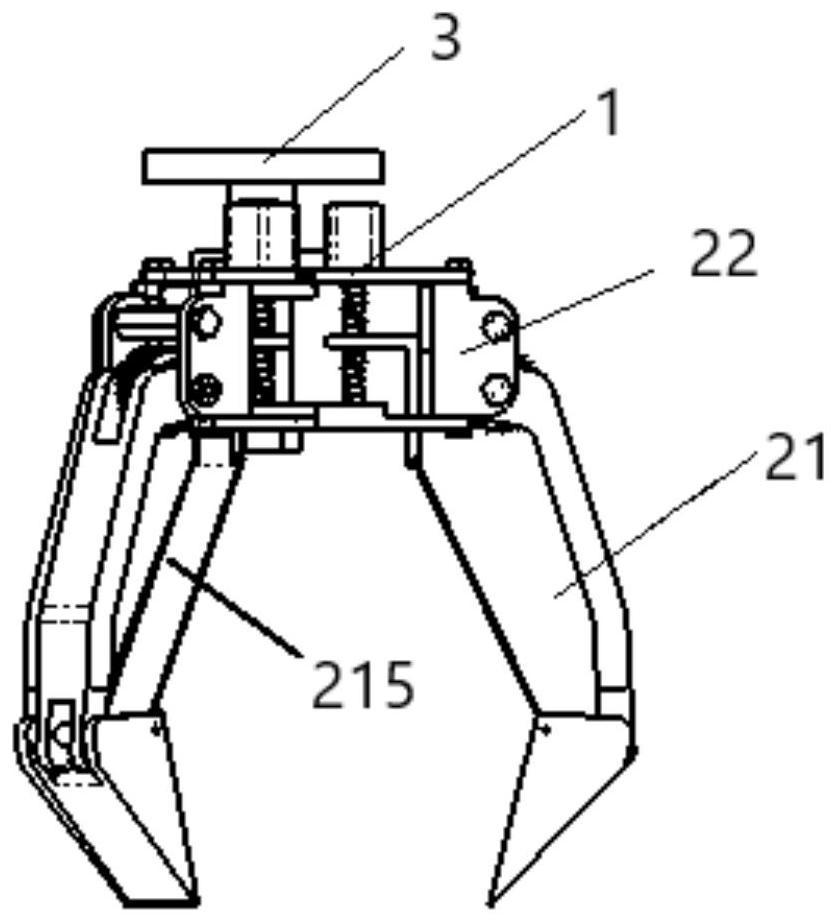

[0079] The grasping unit 2 is arranged on the outside of the bracket unit and includes multiple sets of single-finger drive mechanisms 21 and angle rotation mechanisms 22, wherein the upper end of one set of single-finger drive mechanisms is hinged to the mounting area of the main bracket; the angle rotation mechanisms are installed on the side At the connecting end of the bracket, a set of single-finger driving mechanism is hinged at each rotating end, ...

Embodiment 3

[0090] Embodiment 3 The difference between the semi-flexible multi-fingered manipulator based on the mild steel belt and the toroidal worm described in this embodiment and the embodiment 1 is that the rest of the structure remains the same: the grasping unit includes three sets a single-finger driving mechanism and two sets of angle rotation mechanisms, wherein the first set of single-finger driving mechanism is installed on the main bracket, the second set and the third set of single-finger driving mechanism are installed on the two connecting ends of the side brackets, and The second set and the third set of single-finger drive mechanisms respectively correspond to a set of angle rotation mechanisms.

Embodiment 4

[0091] Embodiment 4 The difference between the semi-flexible multi-fingered manipulator based on the mild steel belt and the toroidal worm described in this embodiment and the embodiment 1 is that the rest of the structure remains consistent: the semi-flexible multi-fingered manipulator is also It includes a mechanical self-locking mechanism, which is used to prevent safety accidents such as falling of the target due to power failure and insufficient drive during work. Among them, when the lead angle of the toroidal worm is smaller than the equivalent friction angle between the worm gear teeth, it has a reverse The stroke self-locking feature can realize that in the case of loss of drive, within the allowable range of the load of the worm wheel and worm, relying on mechanical self-locking to ensure that the finger arm can still maintain the folded state, ensuring safe and reliable transportation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com