A titanium and its alloy motor material welding process and its clamping device with adjustment function

A welding clip and alloy technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of low strength and toughness of titanium metal, reduce work efficiency, and narrow application range, so as to improve practicability and work efficiency , the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

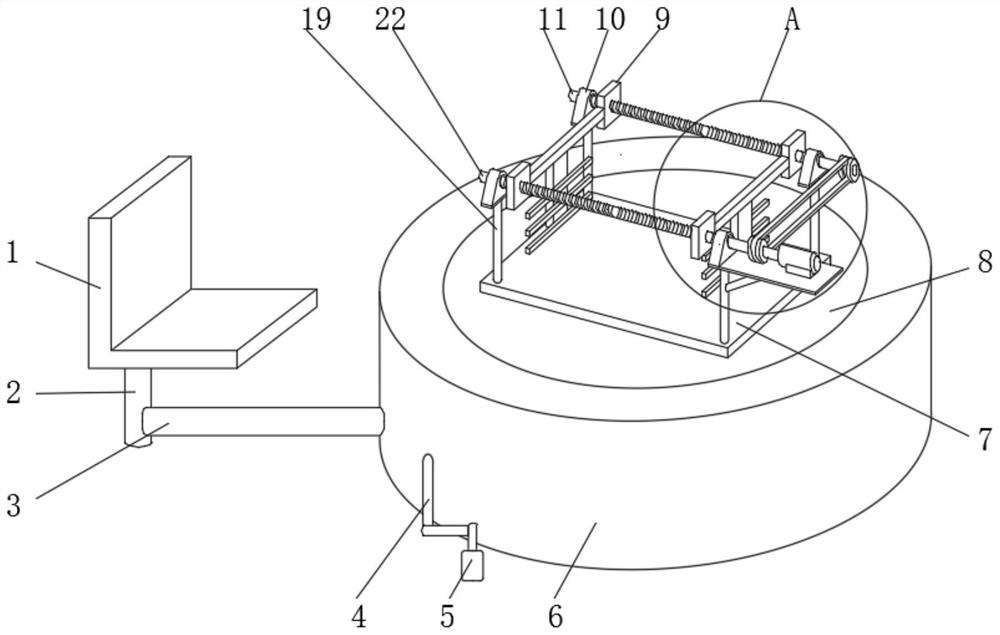

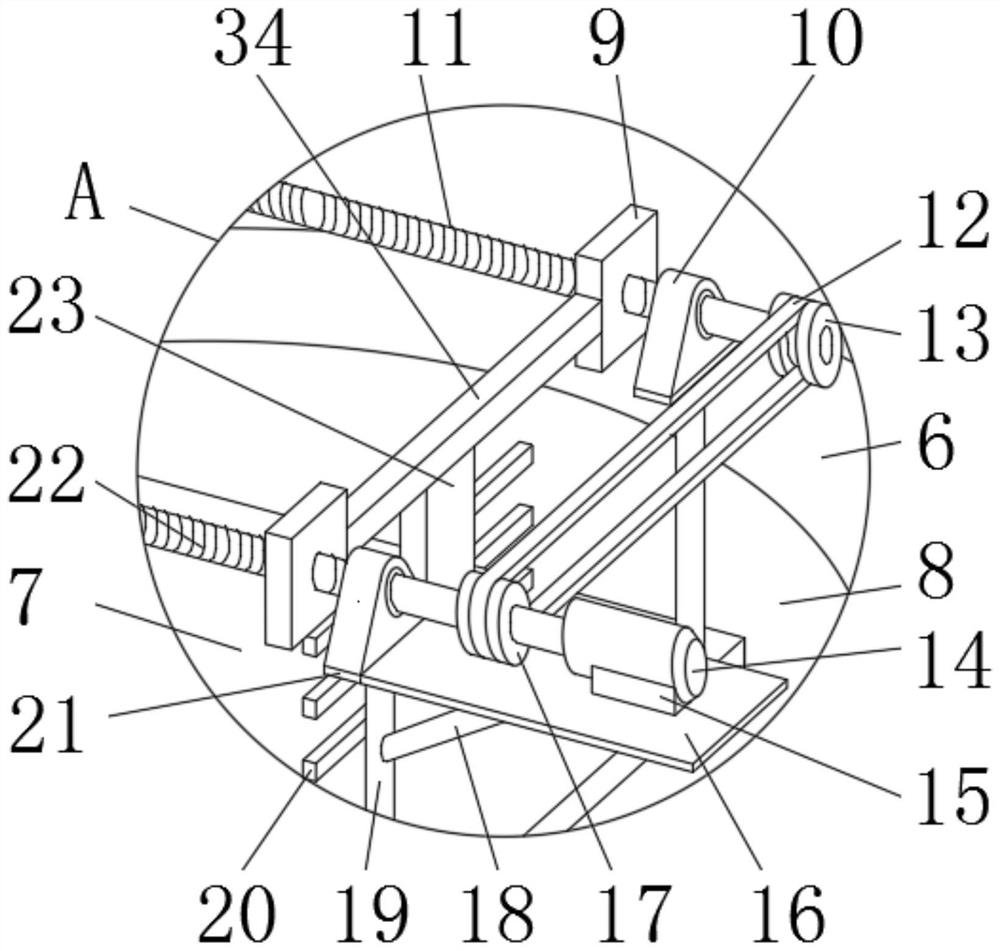

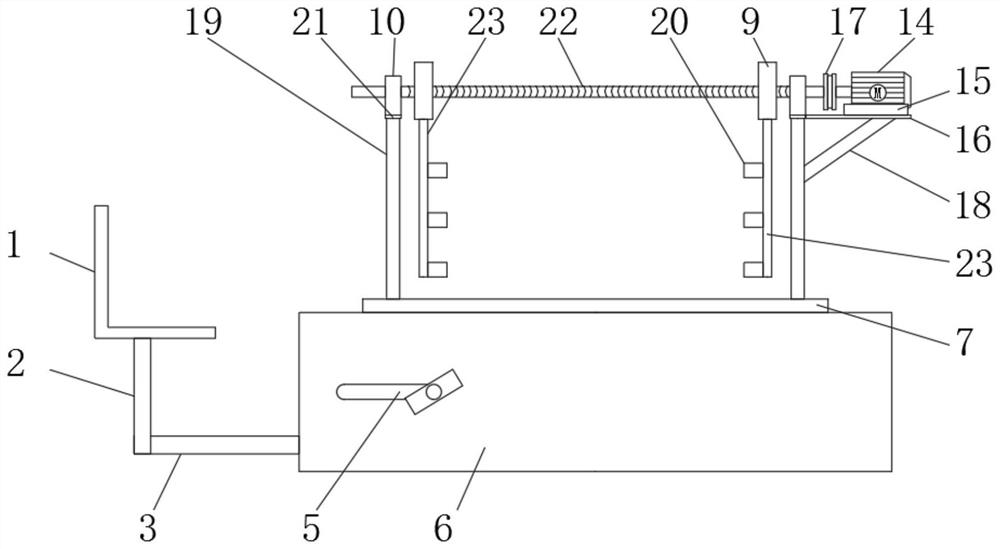

[0039] A titanium with regulating function, the formula includes: titanium and a regulating agent, the parts by weight of each component are: 87.5 parts of titanium and 9.5 parts of regulating agent.

[0040] A titanium alloy motor material welding clamping device with adjustment function, including a seat 1, a support column 2, a connecting arm 3, a first fixed shaft 4, a pedal 5, a base 6, a workbench 7, a turntable 8, a movable Block 9, fixed base 10, first two-way lead screw 11, belt 12, driven pulley 13, motor 14, pad 15, first mounting plate 16, driving pulley 17, support rod 18, fixed arm 19, clamping rod 20. The first fixed block 21, the second two-way lead screw 22, the second mounting plate 23, the drive sprocket 24, the chain 25, the worm 26, the second fixed block 27, the second fixed shaft 28, the support seat 29, the third Fixed shaft 30, driven sprocket 31, worm wheel 32, third fixed block 33, first fixed plate 34 and second fixed plate 35, the bottom of one sid...

Embodiment 2

[0050] A titanium with regulating function, the formula includes: titanium and a regulating agent, the parts by weight of each component are: 90.5 parts of titanium and 12.5 parts of regulating agent.

[0051] A titanium alloy motor material welding clamping device with adjustment function, including a seat 1, a support column 2, a connecting arm 3, a first fixed shaft 4, a pedal 5, a base 6, a workbench 7, a turntable 8, a movable Block 9, fixed base 10, first two-way lead screw 11, belt 12, driven pulley 13, motor 14, pad 15, first mounting plate 16, driving pulley 17, support rod 18, fixed arm 19, clamping rod 20. The first fixed block 21, the second two-way lead screw 22, the second mounting plate 23, the drive sprocket 24, the chain 25, the worm 26, the second fixed block 27, the second fixed shaft 28, the support seat 29, the third Fixed shaft 30, driven sprocket 31, worm wheel 32, third fixed block 33, first fixed plate 34 and second fixed plate 35, the bottom of one si...

Embodiment 3

[0061] A titanium with regulating function, the formula includes: titanium and a regulating agent, the parts by weight of each component are: 90 parts of titanium and 10 parts of regulating agent.

[0062] A titanium alloy motor material welding clamping device with adjustment function, including a seat 1, a support column 2, a connecting arm 3, a first fixed shaft 4, a pedal 5, a base 6, a workbench 7, a turntable 8, a movable Block 9, fixed base 10, first two-way lead screw 11, belt 12, driven pulley 13, motor 14, pad 15, first mounting plate 16, driving pulley 17, support rod 18, fixed arm 19, clamping rod 20. The first fixed block 21, the second two-way lead screw 22, the second mounting plate 23, the drive sprocket 24, the chain 25, the worm 26, the second fixed block 27, the second fixed shaft 28, the support seat 29, the third Fixed shaft 30, driven sprocket 31, worm wheel 32, third fixed block 33, first fixed plate 34 and second fixed plate 35, the bottom of one side o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com