Stirring equipment for brewing wine

A technology of mixing equipment and mixing drum, which is applied in the preparation of alcoholic beverages, mixer accessories, mixers with rotating stirring devices, etc., can solve the problems of low mixing efficiency and inconvenient removal of stirring blades, and achieve convenient removal of stirring blades, The effect of increasing the stirring mixing rate and increasing the stirring rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

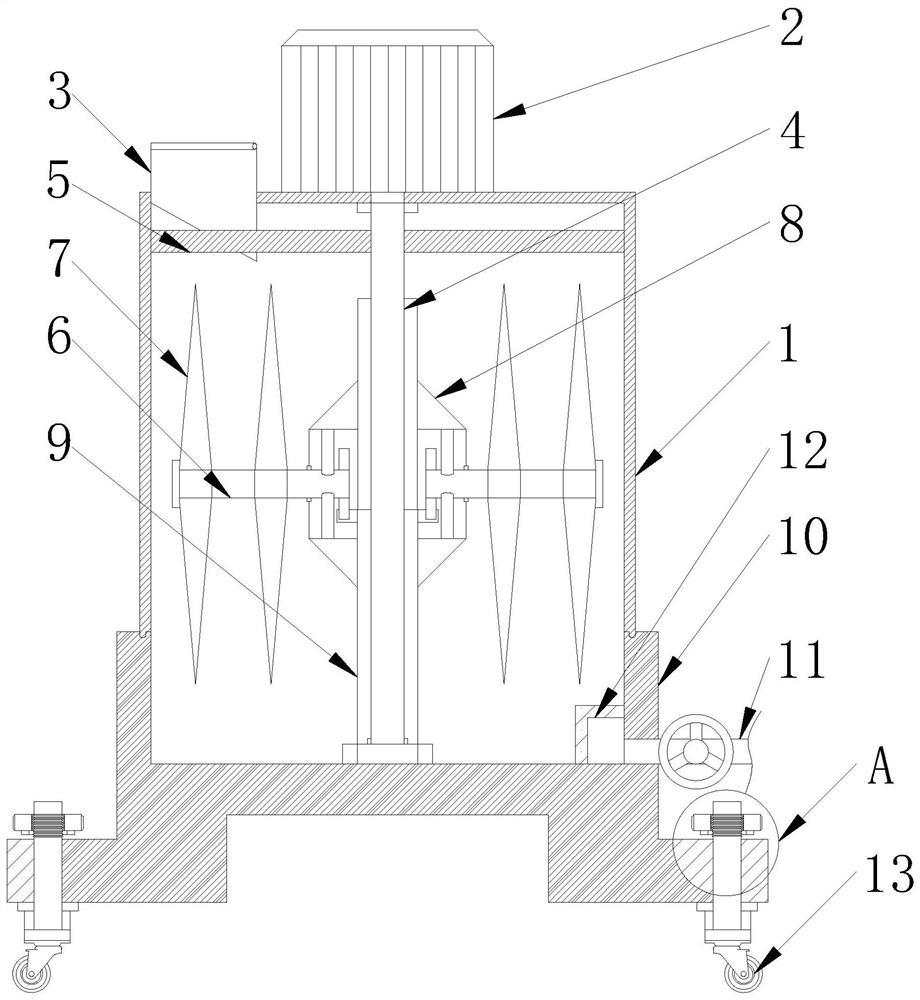

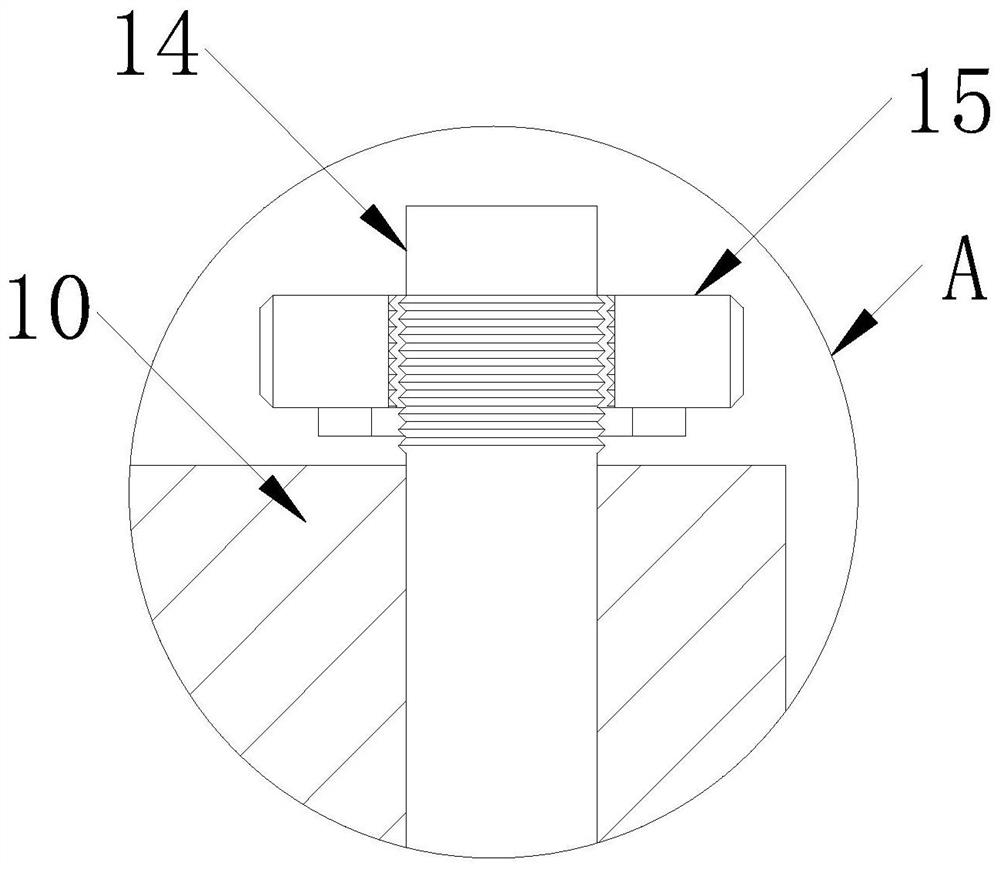

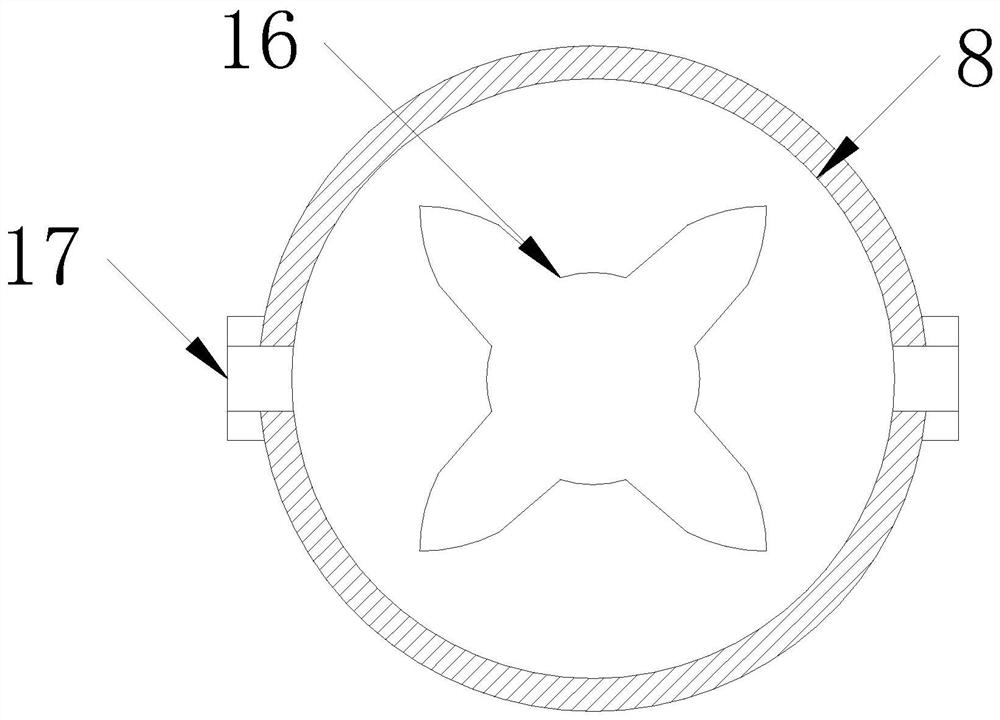

[0029] see Figure 1-5 , the present invention provides the following technical solutions: a stirring device for winemaking, comprising a stirring drum 1, a servo motor 2 is fixedly connected to the top of the stirring drum 1, a feeding port 3 is provided on the top of the stirring drum 1, and the output end of the servo motor 2 A stirring shaft 4 is fixedly connected, and a sealing base 10 is clamped to the bottom of the stirring drum 1 .

[0030] In the present embodiment: the top hinge of the feeding port 3 has a sealing cover, which can ensure the oxygen-deficient state inside the mixing drum 1 when the mixing drum 1 is stirred to make wine, to avoid acidification of winemaking, and the servo motor 2 and a series of need to rotate The connected parts are all connected by sealed rotation, which is the prior art and will not be described too much here.

[0031] The outer surface of the stirring shaft 4 is sleeved with a fixed rod 5, and the bottom of the stirring shaft 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com