Universal tool for detecting bending resistance of automobile anti-collision beam

A technology of anti-collision beams and performance, which is applied in the direction of measuring devices, vehicle testing, and testing the strength of materials by applying a stable bending force. Effect of Experimental Operational Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

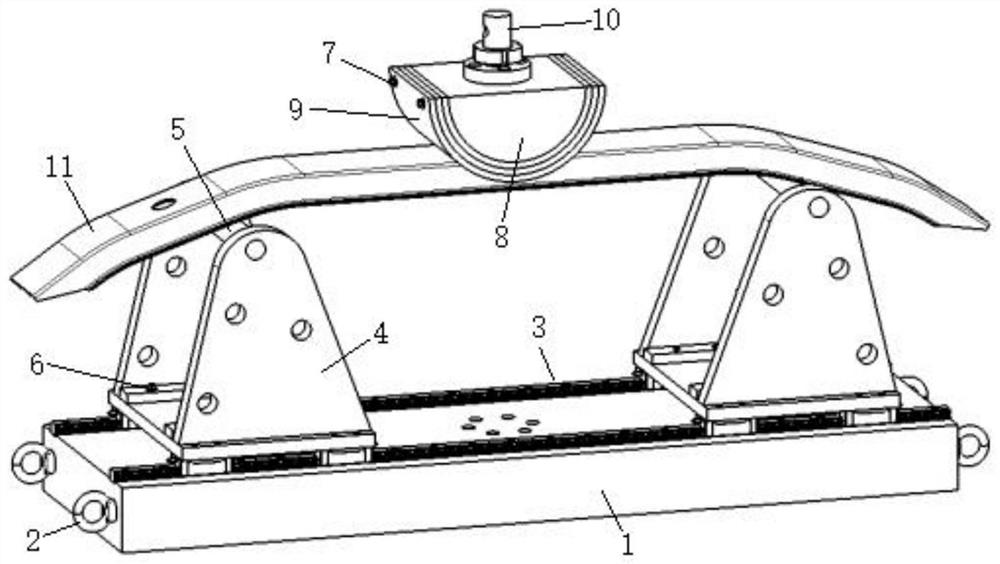

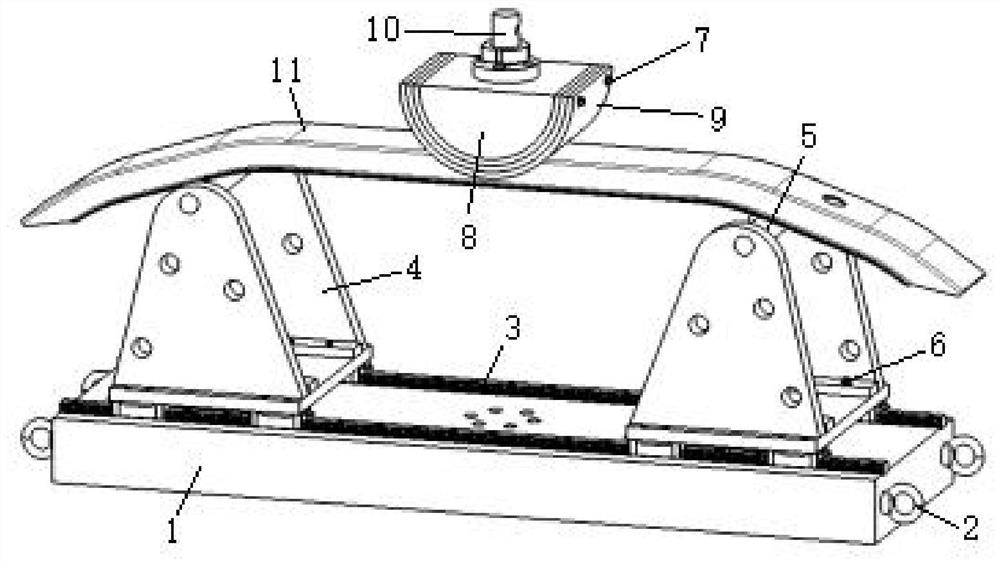

[0019] Such as Figure 1 to Figure 2 As shown in the figure, a general tool for testing the bending resistance performance of an automobile anti-collision beam includes a bottom plate 1, and two roller mounting plate assemblies 4 with adjustable spacing are distributed on the left and right of the bottom plate 1, and each roller mounting plate assembly 4 has a Support rollers 5 with different diameters can be installed;

[0020] It also includes a pressure roller body 8 connected to the press machine, and a pressure roller diameter adjusting piece 9 arranged on the periphery of the pressure roller body 8 to adjust different diameters of the pressure roller body 8 .

[0021] As a further improvement of the present invention, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com