Liftable intermediate support shaft axle housing assembly and manufacturing method thereof

An intermediate support and assembly technology, which is applied in axles, vehicle parts, transportation and packaging, etc., can solve problems such as heavy weight, low production efficiency of tailor-welded square tubes, and limited molding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in conjunction with specific embodiments now.

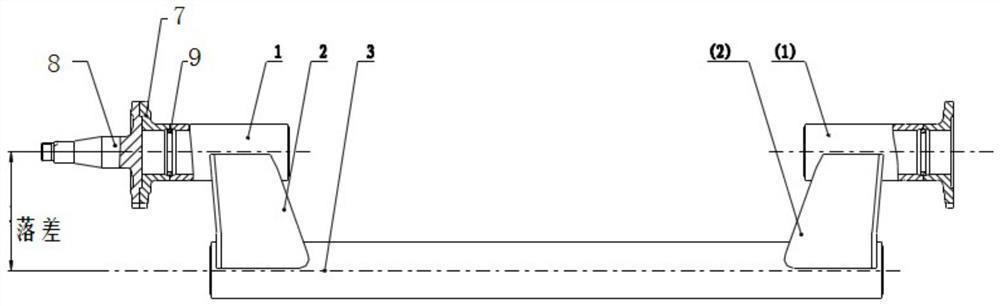

[0032] see figure 1 , figure 2 Shown:

[0033] 1. The fixing ring is welded on the first round tube 1 by electron beam welding to form a round tube assembly, and the first round tube is a short round tube;

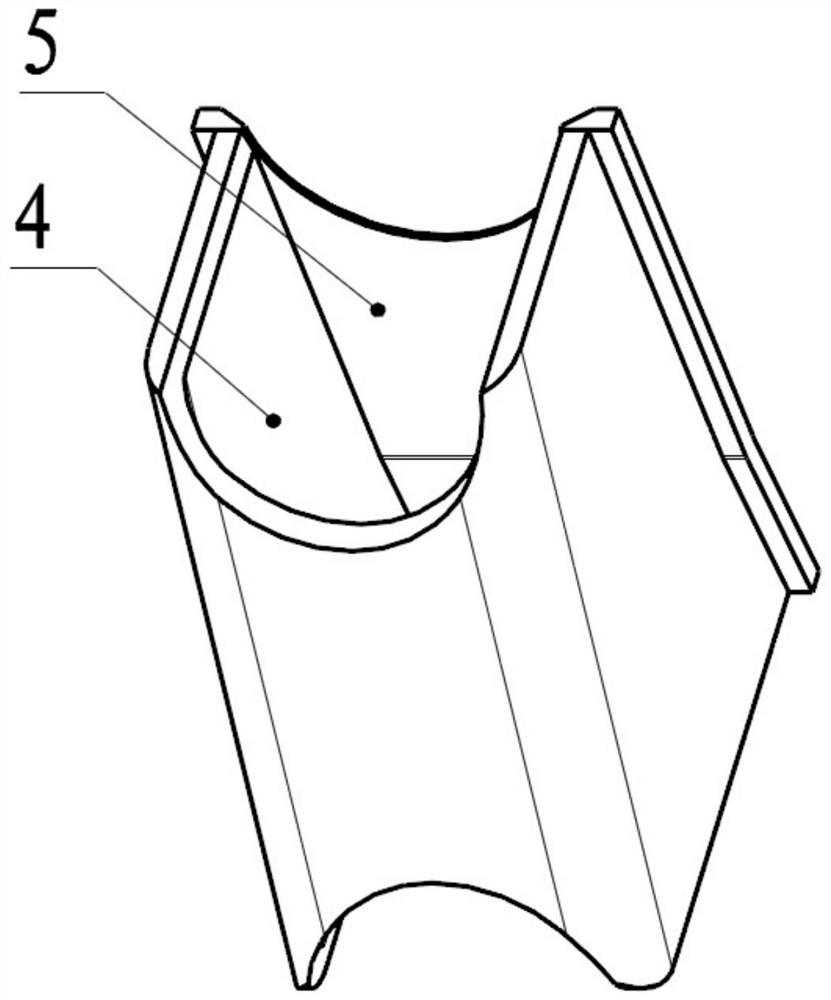

[0034] 2. The plate is bent into a U-shaped bent plate 4, and the U-shaped bent plate 4 and the straight plate 5 are welded into a column 2;

[0035] 3. The upper end surface of the column 2 is welded with the round tube assembly in step 1 by circumferential welding;

[0036] 4. Weld the two assemblies in step 3 on both sides of the second round tube 3, the second round tube is a long round tube.

[0037] 5. The finished shaft head is connected to the fixed ring by bolts.

[0038] In a specific embodiment, the liftable intermediate support shaft and axle housing assembly is made of tailor-welded round tube profiles and bent plates; it includes a first round tube 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com